A kind of sulfate-reducing bacteria metabolic microenvironment responsive composite coating and its preparation method

A composite coating and micro-environment technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of bacterial resistance and biological toxicity that destroy the marine environment and ecological order, and achieve excellent microbial corrosion protection ability, inhibition of microbial corrosion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

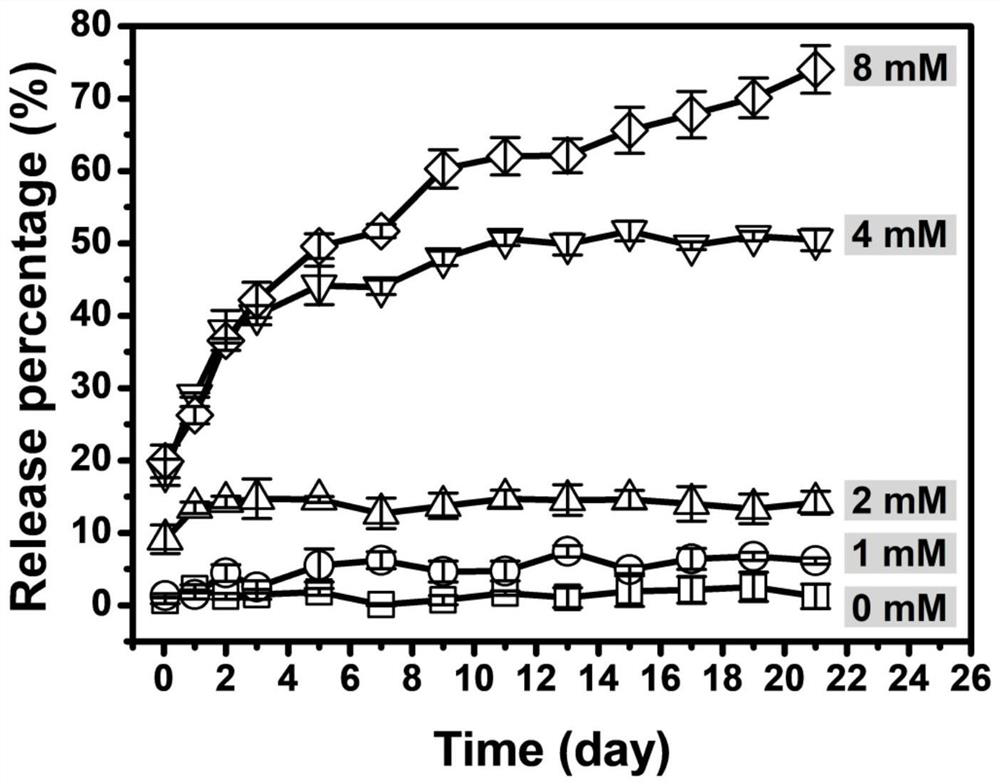

[0043] Example 1 The sulfate-reducing bacteria metabolic microenvironment-responsive composite coating provided in this example mainly includes: an antibacterial surface layer doped with micro-environment-responsive nanoparticles of sulfate-reducing bacteria metabolism and encapsulated with a bactericide, and an antibacterial surface layer doped with encapsulation Anticorrosion primers of microenvironment-responsive nanoparticles of sulfate-reducing bacteria with corrosion inhibitors.

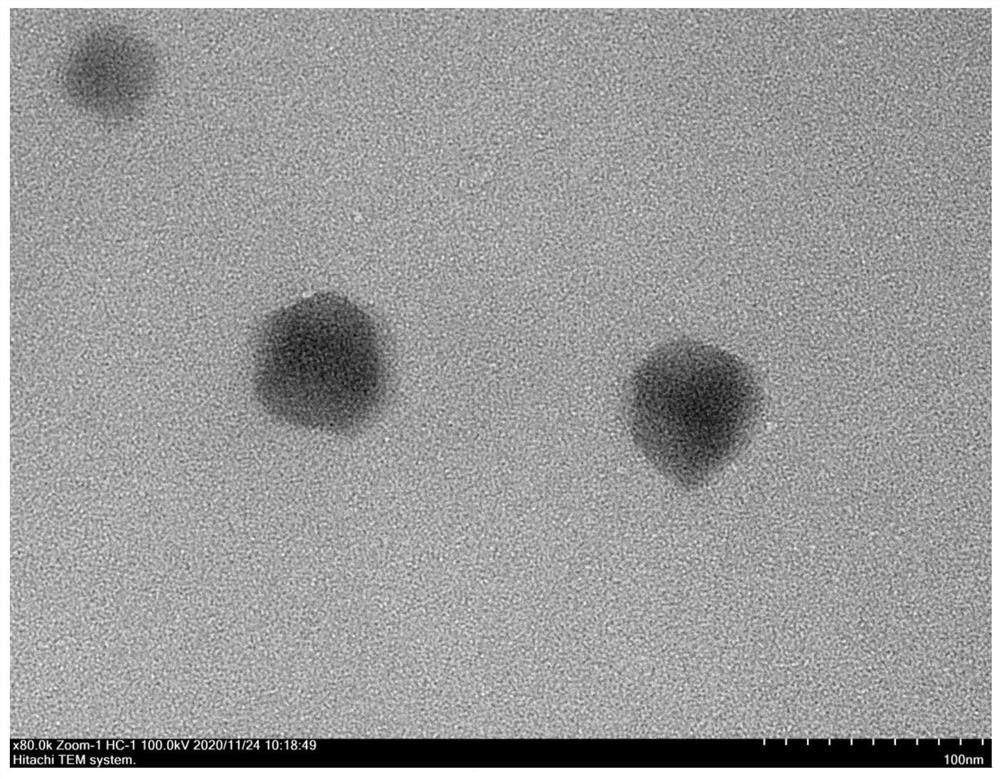

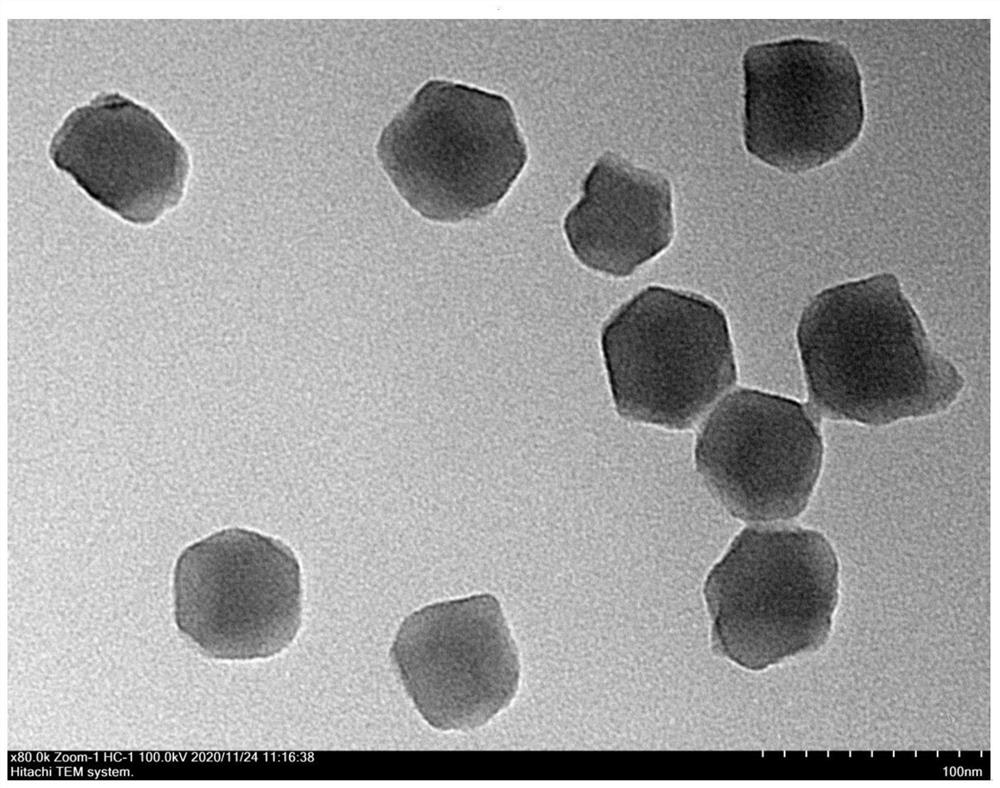

[0044]Among them, the microenvironment-responsive nanoparticles of sulfate-reducing bacteria metabolism use ZIF-90 as the skeleton material, and the antibacterial agent 4,5-dichloro-N-octyl-4-isothiazoline-4,5-dichloro-N-octyl-4-isothiazoline- 3-ketone and corrosion inhibitor benzotriazole.

[0045] The amount of sulfate-reducing bacteria metabolic microenvironment-responsive nanoparticles was 4% of the mass of the antibacterial surface layer base material and the anti-corrosion bottom layer ba...

Embodiment 2

[0054] Example 2 The sulfate-reducing bacteria metabolic microenvironment-responsive composite coating provided in this example mainly includes: an antibacterial surface layer doped with micro-environment-responsive nanoparticles of sulfate-reducing bacteria metabolism and encapsulated with a bactericide, and an antibacterial surface layer doped with encapsulation Anticorrosion primers of microenvironment-responsive nanoparticles of sulfate-reducing bacteria with corrosion inhibitors.

[0055] Among them, the microenvironment-responsive nanoparticles of sulfate-reducing bacteria metabolism use ZIF-90 as the skeleton material, and the antibacterial agent 4,5-dichloro-N-octyl-4-isothiazoline-4,5-dichloro-N-octyl-4-isothiazoline- 3-ketone and corrosion inhibitor benzotriazole.

[0056] The amount of sulfate-reducing bacteria metabolic microenvironment-responsive nanoparticles was 6% of the mass of the antibacterial surface layer base material and the anti-corrosion bottom layer b...

Embodiment 3

[0066] Example 3 The sulfate-reducing bacteria metabolic microenvironment-responsive composite coating provided in this example mainly includes: an antibacterial surface layer doped with micro-environment-responsive nanoparticles for sulfate-reducing bacteria metabolism and encapsulated with a bactericide, and a doping encapsulation Anticorrosion primers of microenvironment-responsive nanoparticles of sulfate-reducing bacteria with corrosion inhibitors.

[0067] Among them, the microenvironment-responsive nanoparticles of sulfate-reducing bacteria metabolism use ZIF-90 as the skeleton material, and the antibacterial agent 4,5-dichloro-N-octyl-4-isothiazoline-4,5-dichloro-N-octyl-4-isothiazoline- 3-ketone and corrosion inhibitor benzotriazole.

[0068] The amount of sulfate-reducing bacteria metabolic microenvironment-responsive nanoparticles was 8% of the mass of the antibacterial surface layer base material and the anti-corrosion bottom layer base material.

[0069] (1) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap