Waste silk recycling and collecting box of chemical fiber spinning equipment

A technology of recycling processing and collection boxes, which is applied in the fields of rayon recycling, fiber chemical characteristics, textiles and papermaking, etc., and can solve the problem of complete collection of waste silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

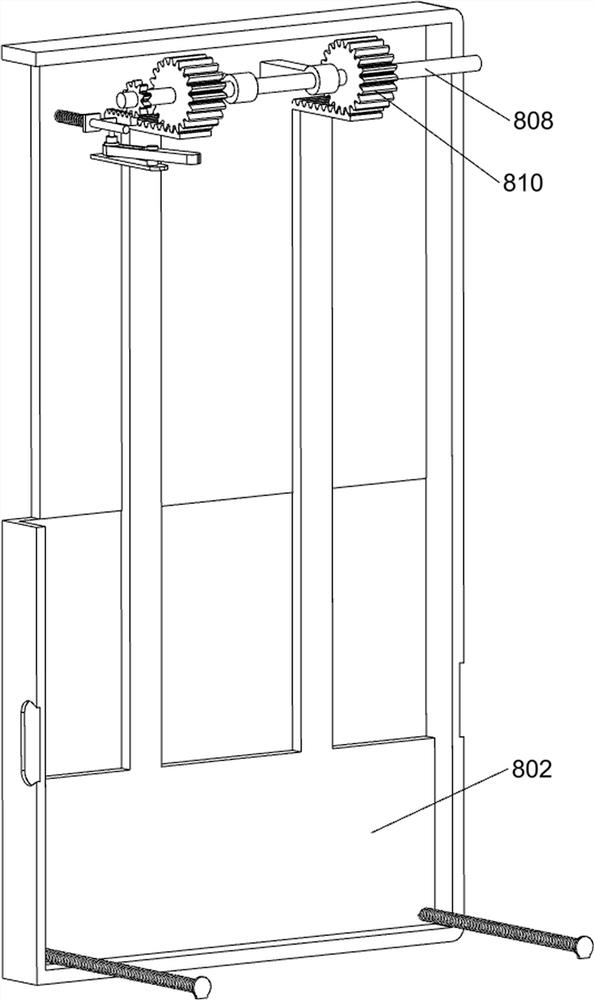

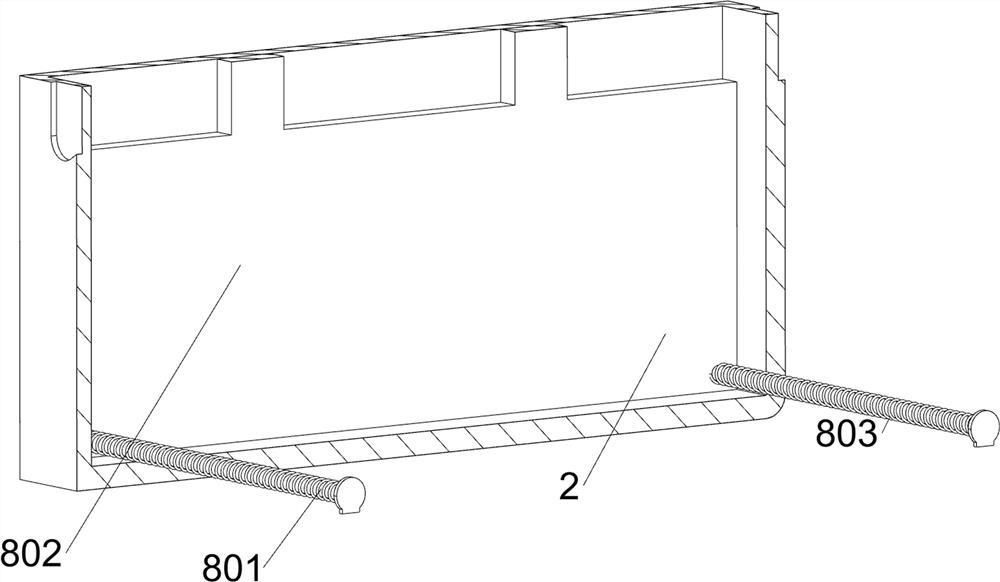

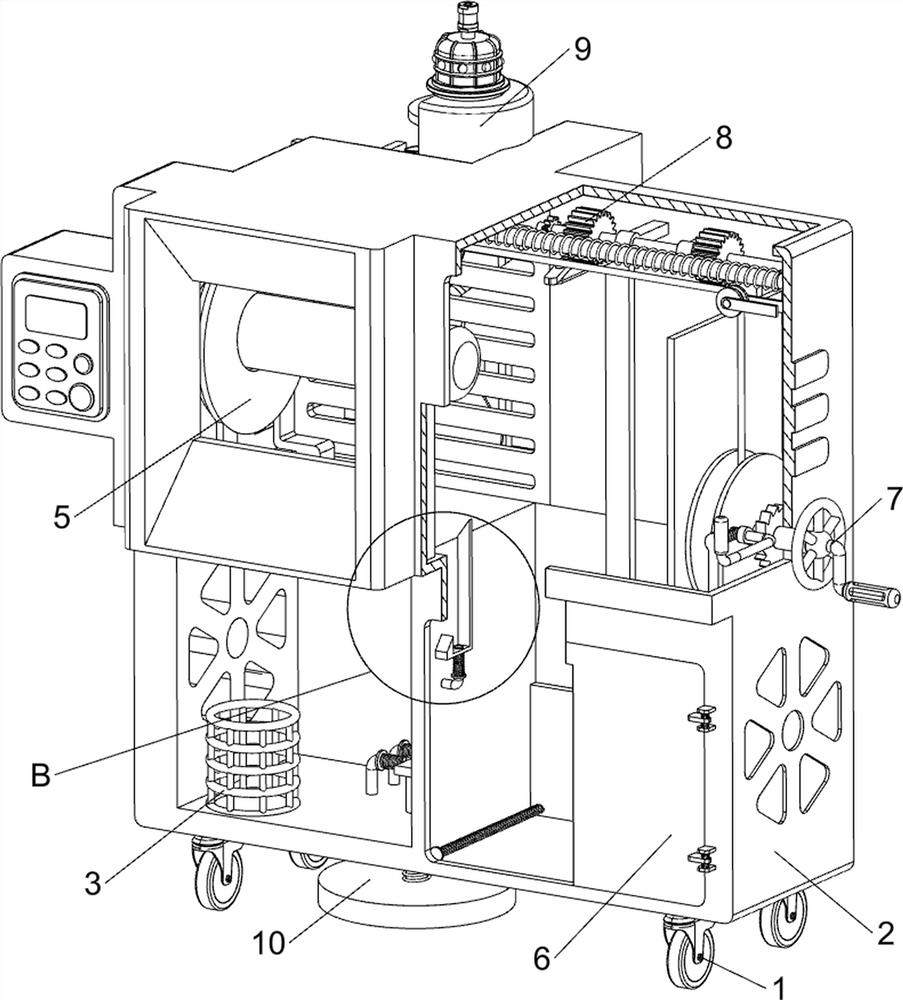

[0032] A waste silk recycling treatment collection box for chemical fiber spinning equipment, such as Figure 1-15 As shown, it includes a universal wheel 1, a collection box 2, a placement frame 3, a push rod 4, a winding assembly 5 and an opening and closing assembly 6, and the left and right sides of the bottom of the collection box 2 are equipped with a universal wheel 1 that is symmetrically rotated forward and backward. The left front side of the collection box 2 is provided with a placement frame 3, the upper right rear side of the collection box 2 is provided with a push rod 4, the upper left side of the collection box 2 is provided with a winding assembly 5, and the lower right side of the collection box 2 is provided with an opening and closing assembly 6.

[0033] The winding assembly 5 includes a control panel 501, a motor 502, a winding shaft 503, a first belt 504, a first rotating shaft 505, a first bevel gear 506 and a fan 507, and the left side of the collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com