Offshore wind power multi-barrel jacket foundation installation and recovery method

A technology for offshore wind power and installation methods, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve problems such as engineering accidents, barrel buckling, and cable tension decoupling, so as to improve the bearing capacity of the foundation, reduce bearing requirements, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

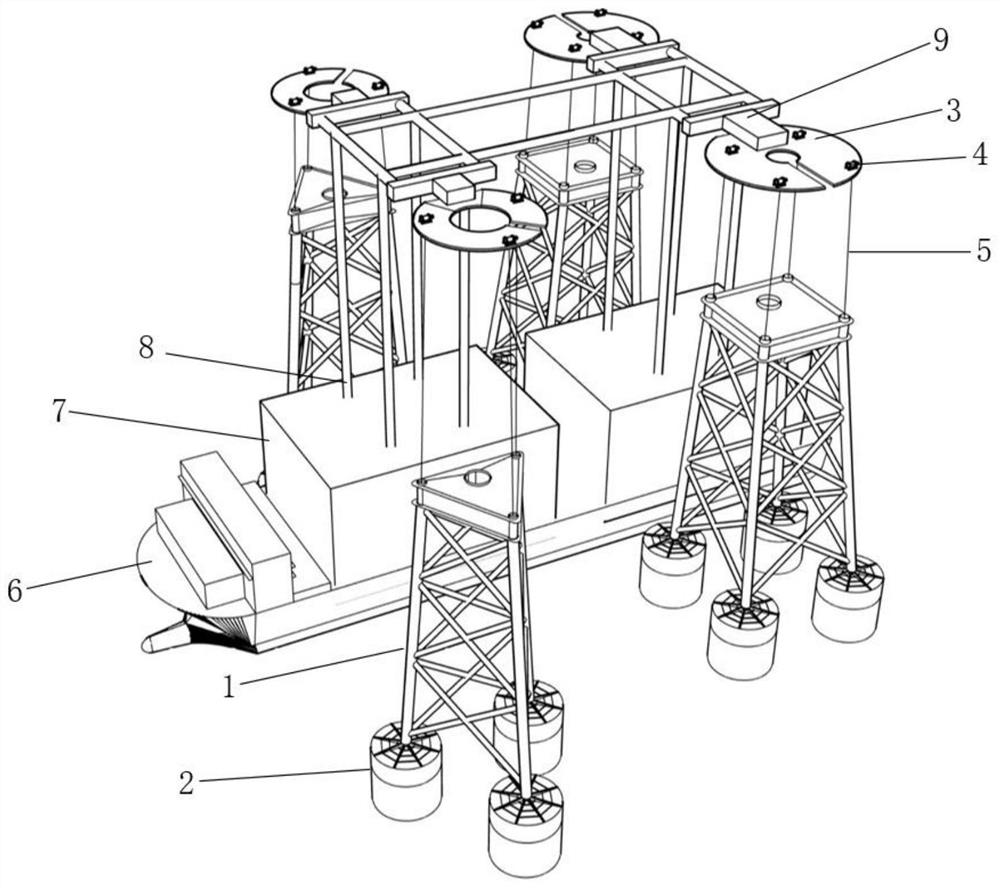

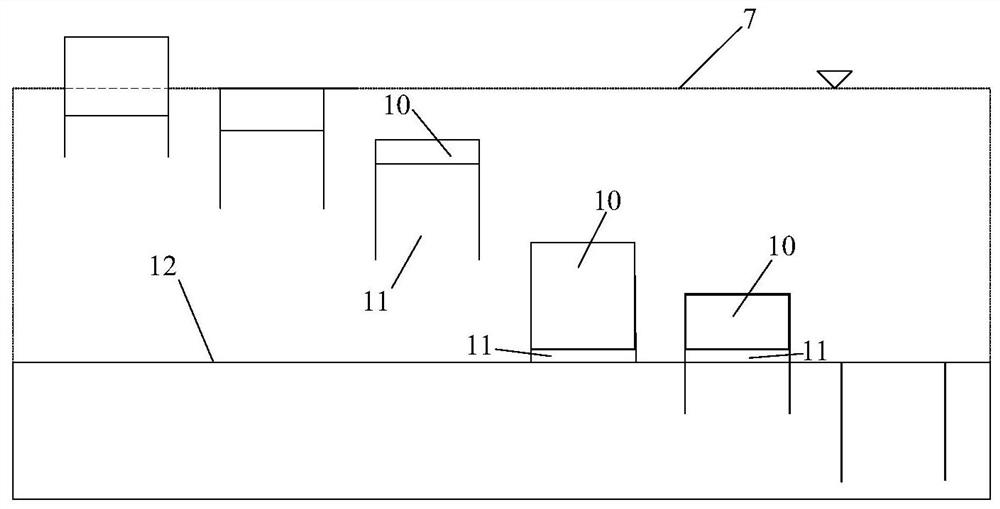

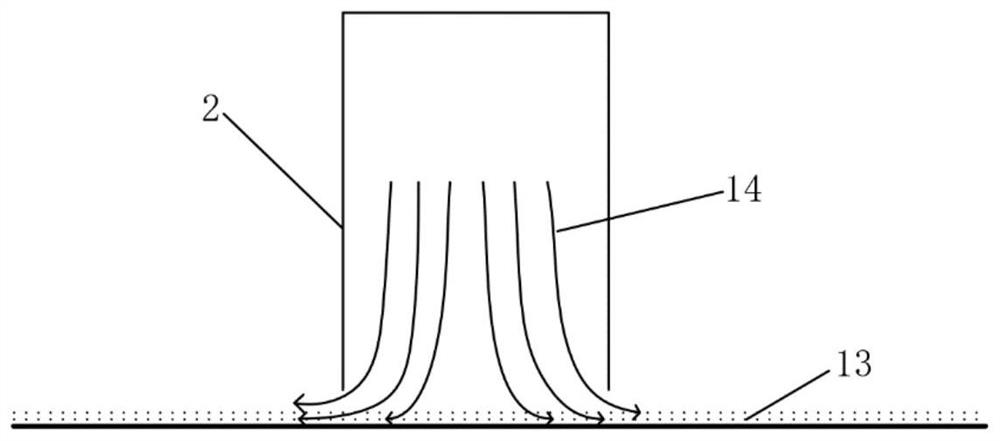

[0046]The present invention provides a method for installation and recovery of offshore wind power multi-tube jacket foundations. After transporting a plurality of multi-tube jacket foundations to the installation sea area by an integrated transport and installation ship 6, the integrated transport and installation ship 6 directly installs and / or Or recover multiple multi-tube jacket foundations, each suction tube 2 of the multi-tube jacket foundation is equipped with a separate suspension cable 5 to control the lowering and / or jacking speed of the multi-tube jacket foundation; the sinking of the multi-tube jacket foundation And / or keep the suction cylinder 2 in the air-holding state during the recovery process to provide a certain buoyancy for the foundation of the multi-tube jacket, and adjust the buoyancy by inflating or deflated the suction cylinder 2 to control the tension of each suspension cable 5, so that the tension of the suspension cables 5 It is always controlled wi...

Embodiment 2

[0079] Such as Figure 4 As shown, the multi-tube jacket foundation and the upper fan integrated machine are floated to the installation site and then installed and recovered, which greatly shortens the time for offshore construction operations. The multi-tube jacket foundation wind power machine includes wind turbines, towers and multi-tube jacket foundations connected sequentially from top to bottom. Jacket foundation wind power complete machine.

[0080] If the foundation of the multi-tube jacket includes three suction tubes 2, the fan head can be adjusted to the direction of a certain suction tube 2 to form an eccentric when the whole machine is installed, and the water content of the suction tube 2 can be adjusted in the process of sinking. Air ratio is adjusted; if the multi-tube jacket foundation includes three suction tubes 2, the fan head can be adjusted to the middle position of two adjacent suction tubes 2 to form an eccentric when the whole machine is installed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com