Construction method for prevention and control of water seepage on the surface of the secondary lining of the tunnel

A construction method and tunnel technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of dampness, non-compactness, etc., and achieve the effects of improving water seepage, good flatness, and improving color inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

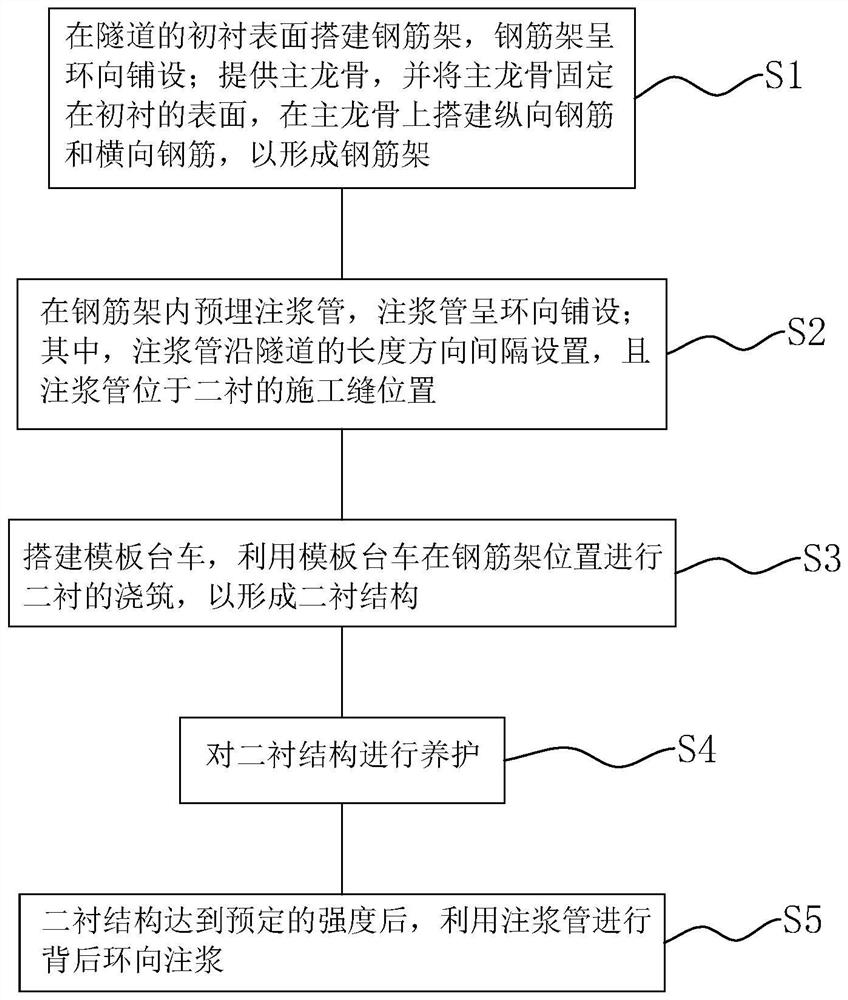

[0042] refer to figure 1 and figure 2 , the construction method for preventing water seepage on the surface of the secondary lining of the tunnel includes the following steps:

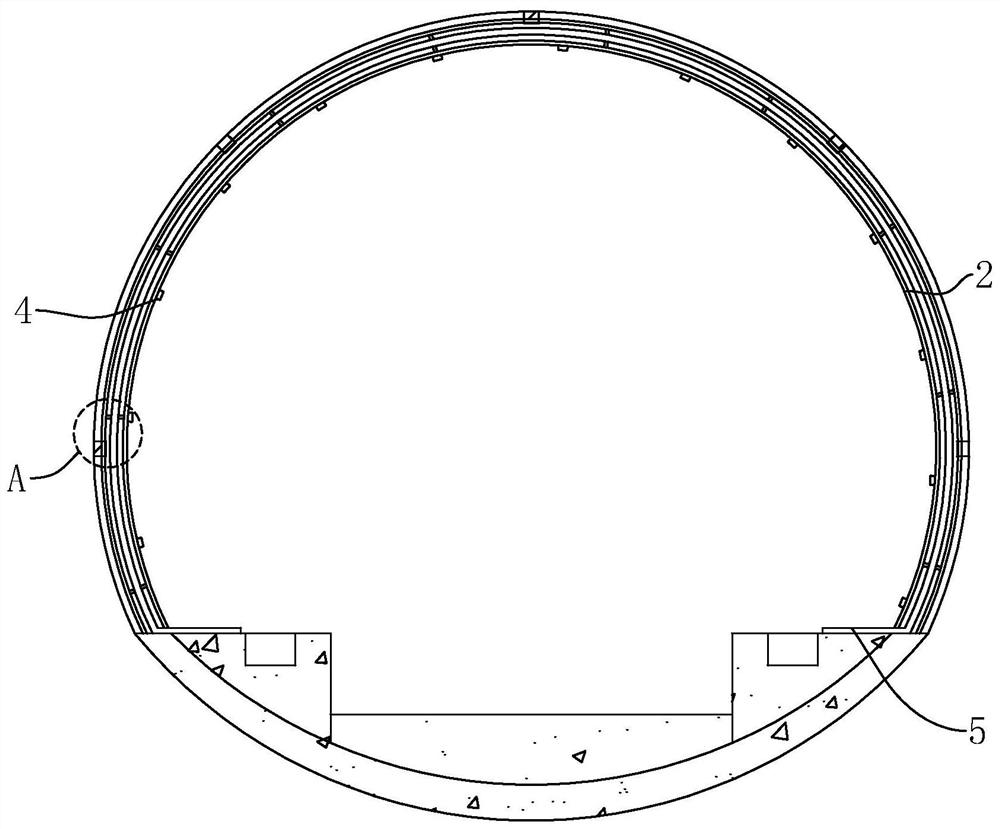

[0043] S1: Build a reinforcement frame on the initial lining surface of the tunnel, and the reinforcement frame is laid in a circumferential direction; provide the main keel 1, and fix the main keel 1 on the surface of the initial lining, build longitudinal reinforcement 2 and transverse reinforcement 3 on the main keel 1, to form a rebar frame.

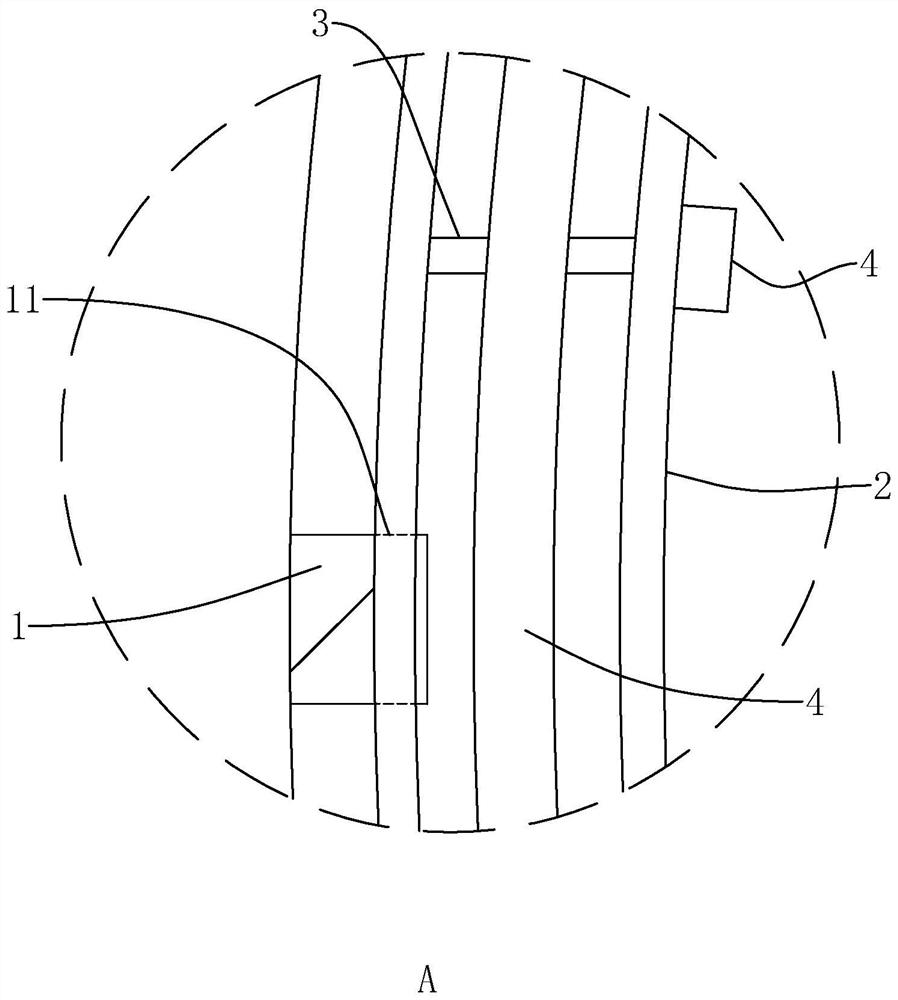

[0044] Specifically, refer to image 3 , in this embodiment, the main keel 1 is fixed on the surface of the initial lining by the embedded screw, the main keel 1 is provided with several positioning grooves 11 equidistant along the length direction, the longitudinal steel bar 2 is bent according to the outline of the tunnel, and the longitudinal The steel bar 2 is clamped in the positioning groove 11, and the longitudinal steel bar 2 and the main keel 1 a...

Embodiment 2

[0057] refer to figure 1 , the construction method for preventing water seepage on the surface of the secondary lining of the tunnel includes the following steps:

[0058] S1: Build a reinforcement frame on the initial lining surface of the tunnel, and the reinforcement frame is laid in a circumferential direction; provide the main keel 1, and fix the main keel 1 on the surface of the initial lining, build longitudinal reinforcement 2 and transverse reinforcement 3 on the main keel 1, to form a rebar frame.

[0059] Specifically, in this embodiment, the main keel 1 is fixed on the surface of the initial lining by pre-embedded screws, and the main keel 1 is provided with a number of positioning grooves 11 equidistant along the length direction, and the longitudinal steel bars 2 are bent according to the outline of the tunnel. , the longitudinal steel bar 2 is clamped in the positioning groove 11, and the longitudinal steel bar 2 and the main keel 1 are welded. The transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com