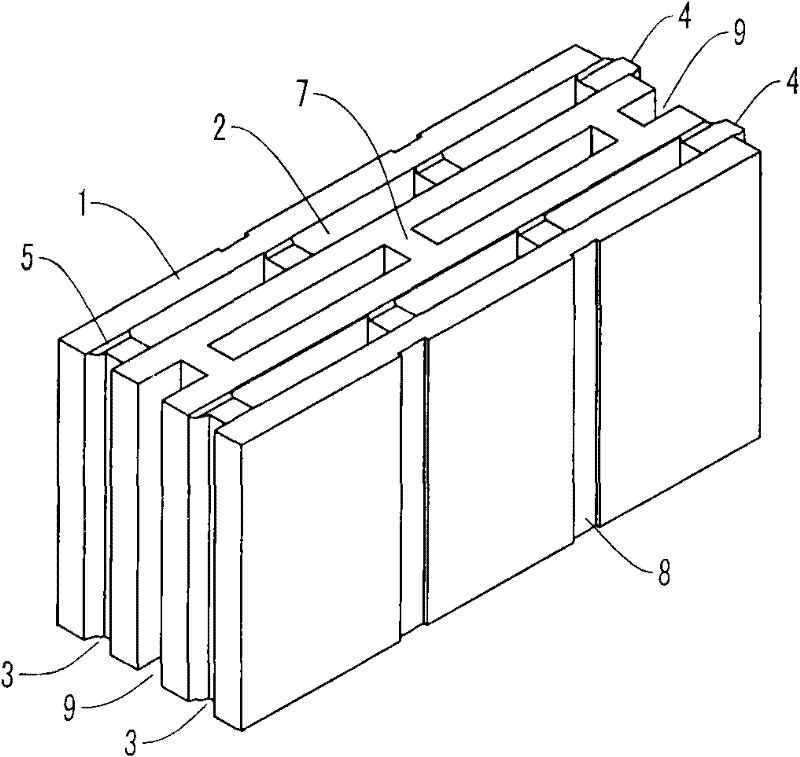

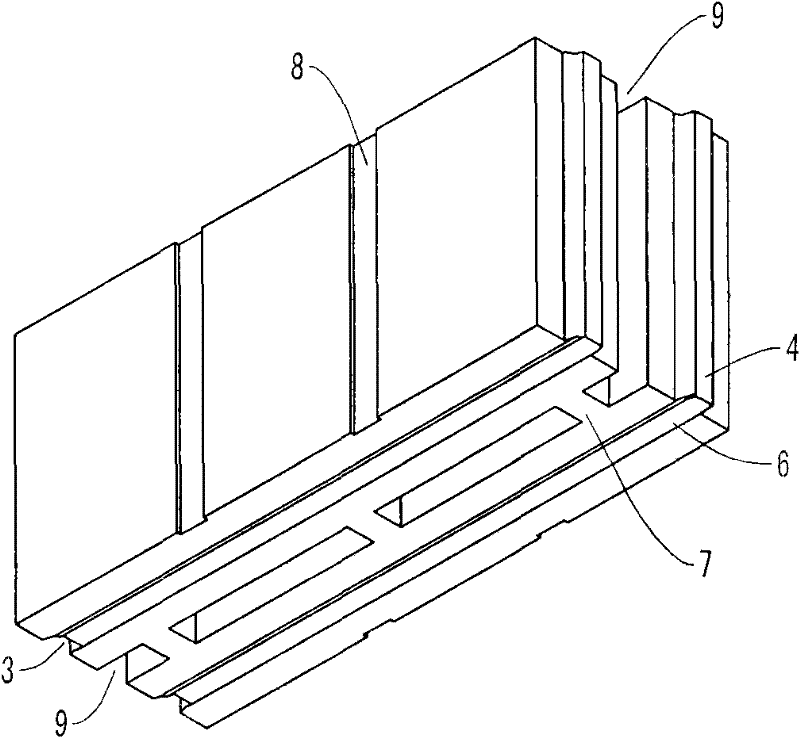

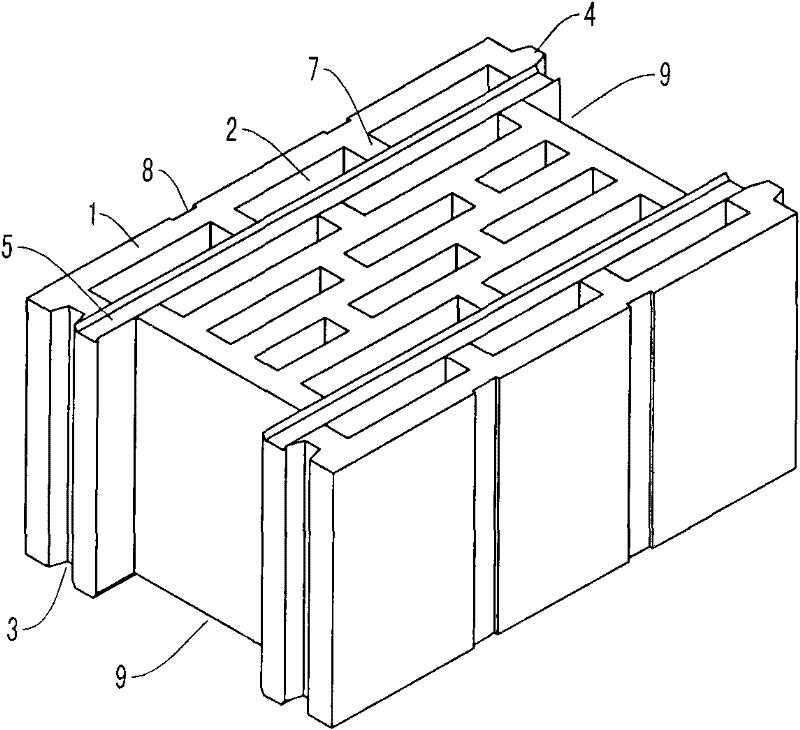

Seepage-prevention anti-shearing heat-insulating hollow building block

A hollow block, shear-resistant technology, applied in the field of building materials, can solve problems such as poor thermal insulation and thermal insulation performance, and achieve the effects of saving engineering costs, reducing environmental protection pressure, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] To produce hollow blocks with a width and thickness of 90-120mm and small specifications, the ratio of raw materials is as follows:

[0037]

[0038] Dry density based on 50% hole void ratio: 1000kg / m 3

[0039] Heat transfer coefficient: K≤1.2(W / m 2 ·K)

Embodiment 2

[0041]To produce medium-sized hollow blocks with a width and thickness of 120mm-150mm, the ratio of raw materials is as follows:

[0042]

[0043] Dry density of 950kg / m2 based on 50% hole void ratio 3

[0044] Heat transfer coefficient: K≤1.0(W / m 2 ·K)

Embodiment 3

[0046] To produce large-scale hollow blocks with a width and thickness of 190mm-240mm, the ratio of raw materials is as follows:

[0047]

[0048]

[0049] Dry density based on 50% hole void ratio: 900kg / m 3

[0050] Heat transfer coefficient: K≤0.8(W / m 2 ·K)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com