Water supply and drainage pipeline with glass fiber reinforced plastics lining and manufacture method thereof

A production method and technology of FRP, applied in the direction of pipeline connection layout, pipes, rigid pipes, etc., can solve the problems of FRP pipelines such as brittle materials, poor bearing capacity, and easy damage, and achieve the effect of long pipe body, long service life and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

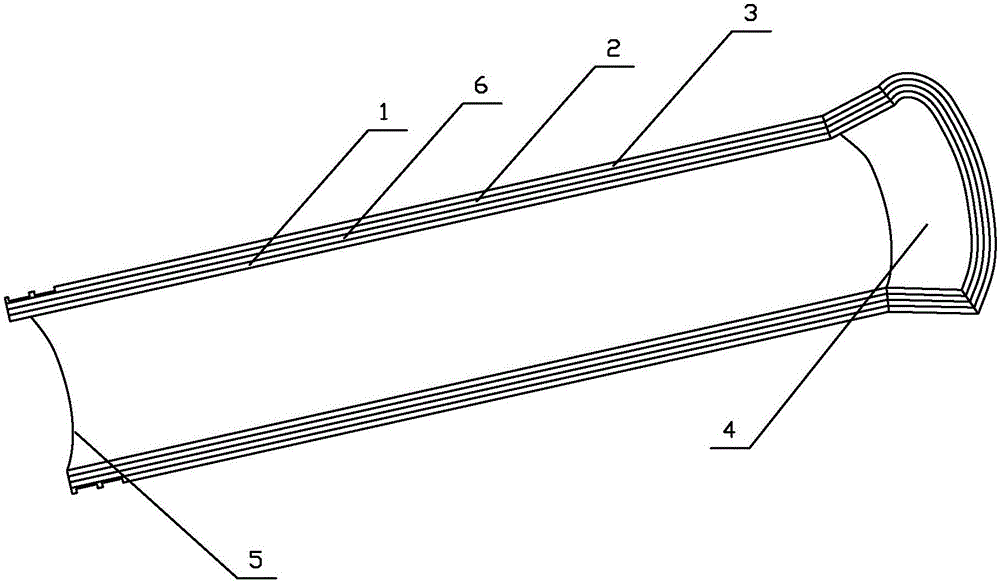

Image

Examples

Embodiment 1

[0053] A method for manufacturing a fiberglass-lined water supply and drainage pipeline:

[0054] S1, select a suitable mold, and set the glass fiber reinforced plastic wear-resistant layer 1 on the mold according to the following method;

[0055] S11. According to the required weight, prepare according to the following ratio: take 80 parts by weight of unsaturated polyester resin, add styrene solution containing 1% cobalt naphthenate and stir evenly, and the part by weight added is 0.3 parts;

[0056] S12, then add the phthalic acid solution of methyl ethyl ketone peroxide containing 10% active oxygen and stir evenly, the added part by weight is 0.4 parts, to obtain glue;

[0057] S13. Take the uniform glue solution obtained in S12 and apply it on the surface of the mold. Put the surface felt from the socket of the mold and put it into the required production length. After putting it, apply a layer of glue solution to make the surface felt soaked in resin , and then put the ...

Embodiment 2

[0064] A method for manufacturing a fiberglass-lined water supply and drainage pipeline:

[0065] S1, select a suitable mold, and set the glass fiber reinforced plastic wear-resistant layer 1 on the mold according to the following method;

[0066] S11. According to the required weight, prepare according to the following ratio: take 120 parts by weight of unsaturated polyester resin, add styrene solution containing 1% cobalt naphthenate and stir evenly, and the number of parts added is 1.2 parts by weight;

[0067] S12, then add the phthalic acid solution of methyl ethyl ketone peroxide containing 10% active oxygen and stir evenly, and the added parts by weight are 1.5 parts to obtain glue;

[0068] S13. Take the uniform glue solution obtained in S12 and apply it on the surface of the mold. Put the surface felt from the socket of the mold and put it into the required production length. After putting it, apply a layer of glue solution to make the surface felt soaked in resin , ...

Embodiment 3

[0075] A method for manufacturing a fiberglass-lined water supply and drainage pipeline:

[0076] S1, select a suitable mold, and set the glass fiber reinforced plastic wear-resistant layer 1 on the mold according to the following method;

[0077] S11. According to the required weight, prepare according to the following ratio: take 100 parts by weight of unsaturated polyester resin, add styrene solution containing 1% cobalt naphthenate and stir well, and the number of parts added is 0.7 parts by weight;

[0078] S12, then add the phthalic acid solution of methyl ethyl ketone peroxide containing 10% active oxygen and stir evenly, the part by weight added is 1.0 parts, to obtain glue;

[0079] S13. Take the uniform glue solution obtained in S12 and apply it on the surface of the mold. Put the surface felt from the socket of the mold and put it into the required production length. After putting it, apply a layer of glue solution to make the surface felt soaked in resin , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com