Method for safely removing algae and settling algae based on sepiolite

A technology of sepiolite and algae, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, etc. Fast algae speed and complete algae removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

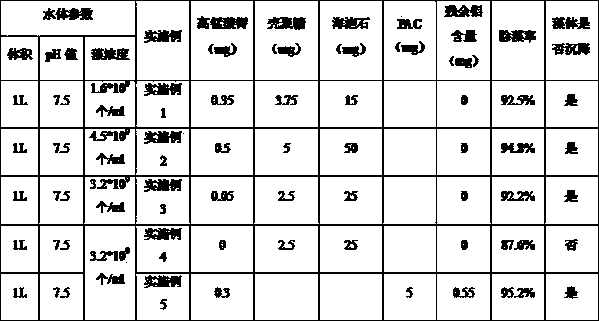

Embodiment 1

[0016] In 1L algal concentration is 1.6*10 9 0.35 mg of potassium permanganate was added to simulated water with a pH of 7.5, pre-oxidized for 15 minutes, and then 3.75 mg of chitosan and 15 mg of sepiolite were added. Stir at a speed of 400 rpm for 5 minutes to mix the powder. During the stirring process, it can be observed that the algae in the water body begin to agglomerate; then stir at a slow speed of 30 rpm for 15 minutes, and it can be observed that the aggregates gradually increase. , and the volume of the same condensate is getting bigger and bigger. After standing still for half an hour, the algae condensate sinks to the bottom of the water, the water quality is clear, and the algae removal efficiency can reach 92.5%.

Embodiment 2

[0018] In 1L algal concentration is 4.5*10 9 0.5mg potassium permanganate was added in the simulated water body with pH of 7.5, and after pre-oxidation for 15 minutes, 5mg chitosan and 50mg sepiolite were added. Stir at a speed of 400 rpm for 5 minutes to mix the powder. During the stirring process, it can be observed that the algae in the water body begin to agglomerate; then stir at a slow speed of 30 rpm for 15 minutes, and it can be observed that the aggregates gradually increase. , and the volume of the same condensate is getting bigger and bigger. After standing still for half an hour, the algae condensate sinks to the bottom of the water, the water quality is clear, and the algae removal efficiency can reach 94.8%.

Embodiment 3

[0020] In 1L algal concentration is 3.2*10 9 0.05 mg potassium permanganate per ml, pH 7.5 in the simulated water, pre-oxidized for 15 minutes, then added 2.5 mg chitosan and 25 mg sepiolite. Stir at a speed of 400 rpm for 5 minutes to mix the powder. During the stirring process, it can be observed that the algae in the water body begin to agglomerate; then stir at a slow speed of 30 rpm for 15 minutes, and it can be observed that the aggregates gradually increase. , and the volume of the same condensate is getting bigger and bigger. After standing still for half an hour, the algae condensate sinks to the bottom of the water, the water quality is clear, and the algae removal efficiency can reach 92.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com