Portable electric detonator

An electric detonator, portable technology, applied in the field of portable electric detonators, can solve the problems of low production efficiency, inconvenient handling, unfavorable continuous production, etc., to improve production speed and production efficiency, simplify structure and assembly process , The effect of simplifying the assembly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

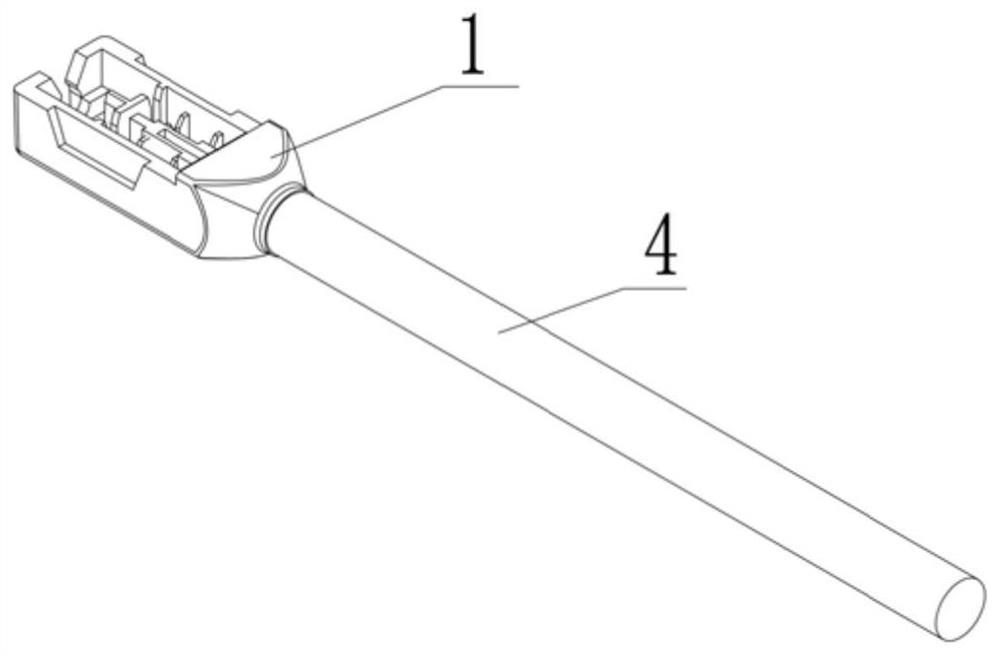

[0041] This embodiment provides a portable electric detonator, such as figure 1 As shown, it includes an insulated electrical connector 1, an electric ignition element 2 and a basic detonator 4.

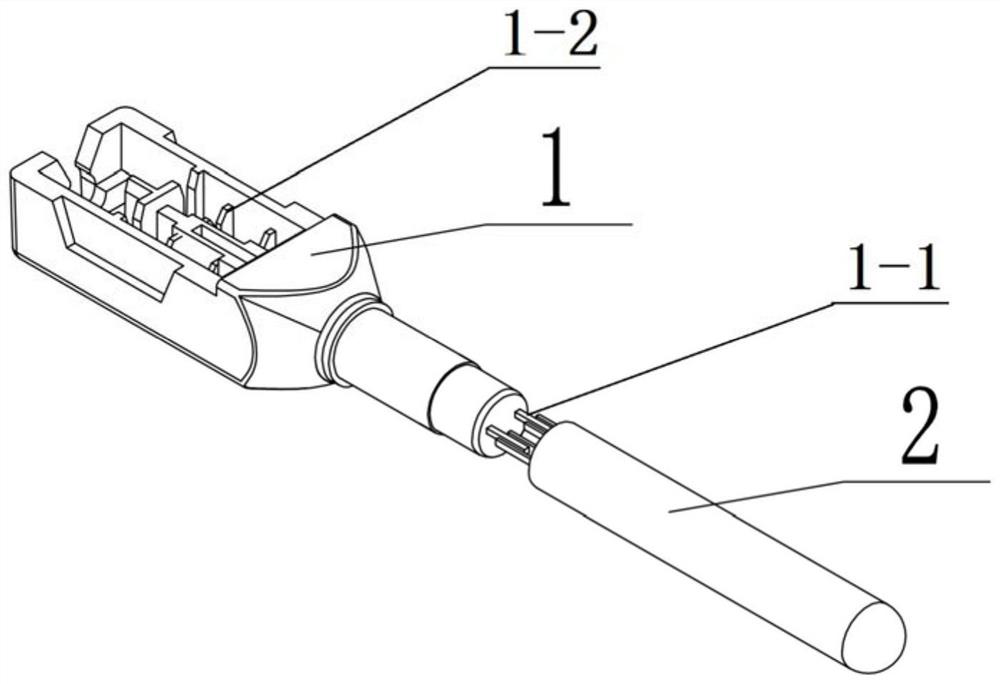

[0042] Such as figure 2As shown, the insulating connector 1 is a structure in which one end of the metal terminal is covered with an insulating elastic material as an electric detonator bayonet plug to realize the electrical connection with the relevant electronic devices and the mechanical connection with the extension parts. The other end of the insulating connector 1 Used as a junction box for extension connecting wires, the insulating connector 1 is an integrated structure composed of an electric detonator bayonet plug and a junction box. Both the electric detonator bayonet plug and the junction box housing are insulating materials, preferably plastic. The exposed metal terminal part of the bayonet plug of the electric detonator is used as the metal terminal 1-1, and the insula...

Embodiment 2

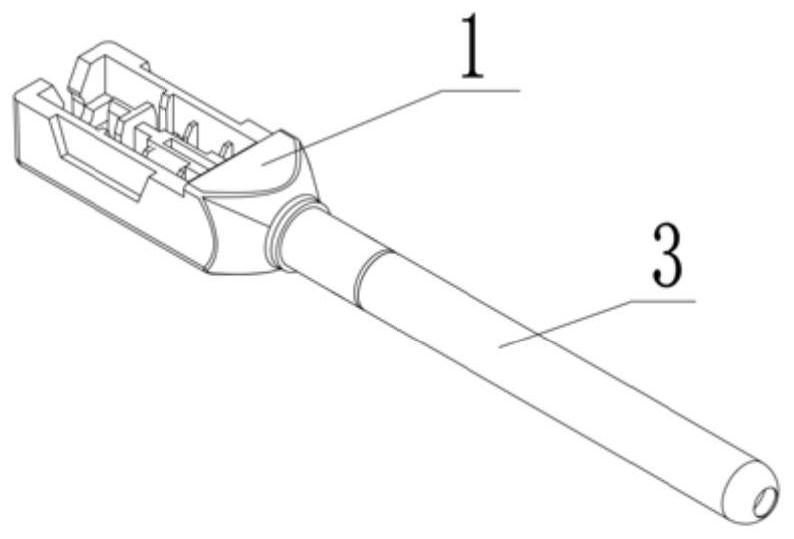

[0049] On the basis of Embodiment 1, the electric detonator further includes a reinforcing tube 3 .

[0050] The outer diameter of the small-diameter section of the electric-related detonator bayonet plug of the insulating connector 1 is consistent with the inner diameter of the reinforcing tube 3 .

[0051] Such as image 3 As shown, the reinforcing tube 3 is sleeved outside the electric ignition element 2 , and the opening end of the reinforcing tube 3 is engaged or glued to the small diameter section of the bayonet plug of the electric detonator of the insulating connector 1 . The basic detonator 4 is set outside the reinforcing tube 3, and the end of the basic detonator 4 is engaged or bonded with the large-diameter section of the electric detonator bayonet plug of the insulating connector 1 to form a sealed structure.

[0052] The insulated connector 1 is extended through the metal terminals 1-1 and clamping terminals 1-2 at both ends, and is electrically connected with ...

Embodiment 3

[0054] On the basis of Embodiment 1 or Embodiment 2, the electric detonator is clamped with the extension leg 5 through the clamping terminal 1-2 on the insulating connector 1, and the extension leg 5 and its junction box are added to form A self-contained and integrated electric detonator, such as Figure 4 , Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com