Valve airtightness detection equipment

An air tightness detection and valve technology, which is used in mechanical valve testing, liquid tightness measurement using liquid/vacuum degree, etc. The effect of convenient later viewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings.

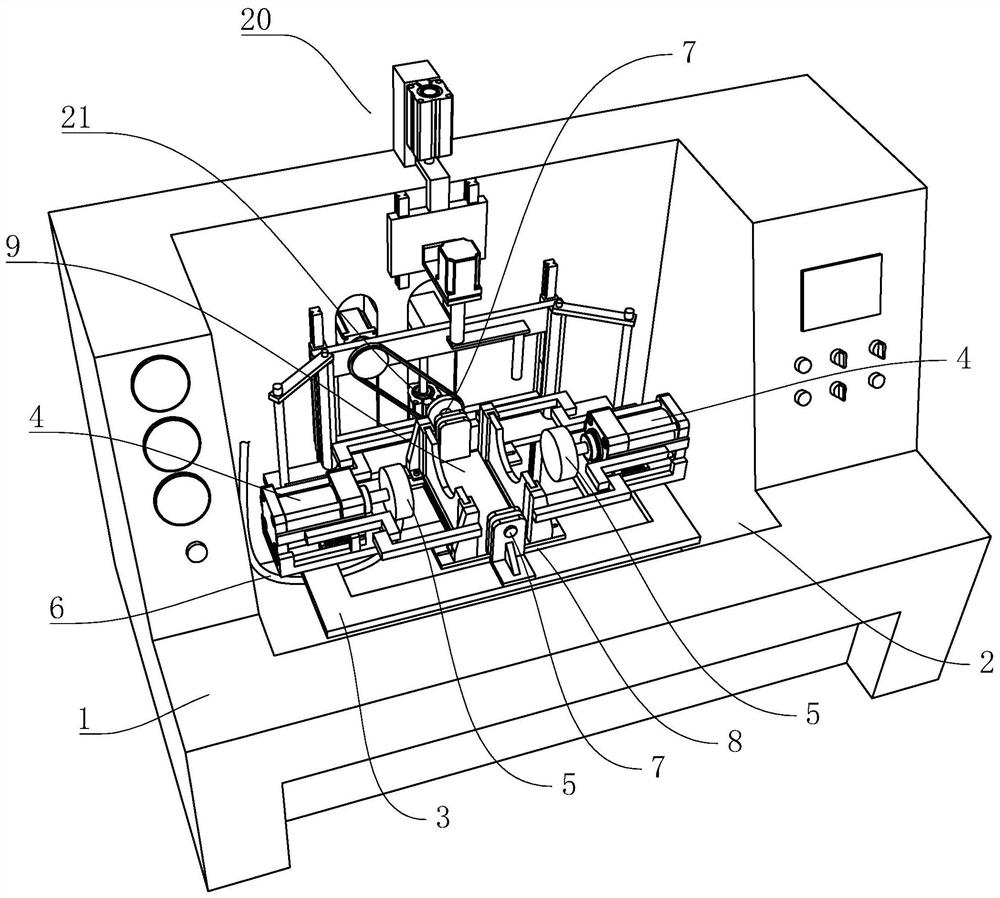

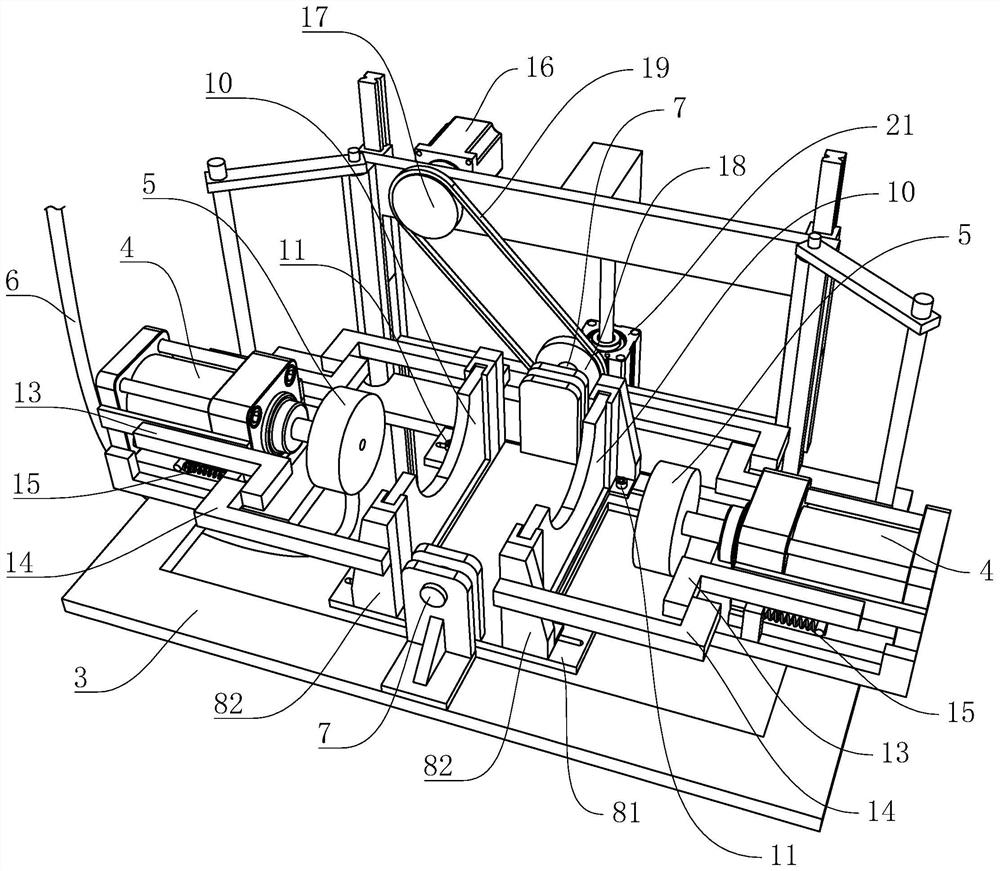

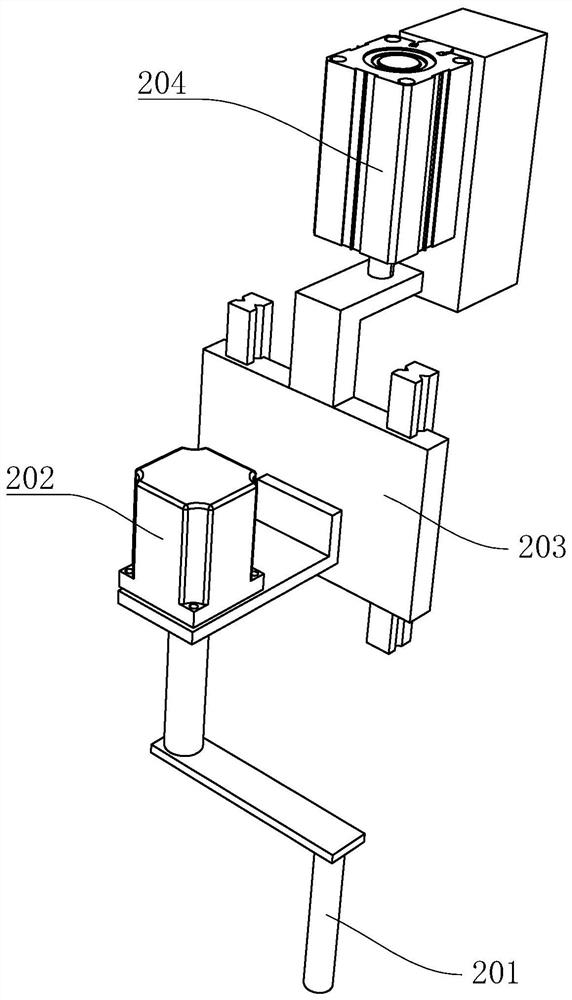

[0034] refer to Figure 1 to Figure 5 , a valve air tightness detection equipment, including a body 1 and a reservoir 2 formed in the body 1, a lift platform 3 is arranged above the reservoir 2, the lift platform 3 is slidably arranged on the body 1, and the body 1 There is a second driving member 21 for driving the lifting platform 3 to lift and lower. The second driving member 21 is an air cylinder. The cylinder body of the air cylinder is fixedly arranged on the fuselage 1 , and the piston rod is fixedly connected to the lifting platform 3 . Driving parts 4 are symmetrically arranged on the lifting platform 3 , and sealing parts 5 are connected to each driving part 4 , and an air intake pipe 6 is connected to one sealing part 5 . A detection platform 8 is disposed on the lifting platform 3 at a position between the two seals 5 through a rotating shaft 7 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com