Device for bridge deck construction and construction method thereof

A technology in the direction of bridges and sliding, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of too thick concrete, small concrete slump, waste of time, etc., to reduce workload, slow down accumulation speed, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 2-7 The application is described in further detail.

[0044] The embodiment of the present application discloses a device for bridge deck construction.

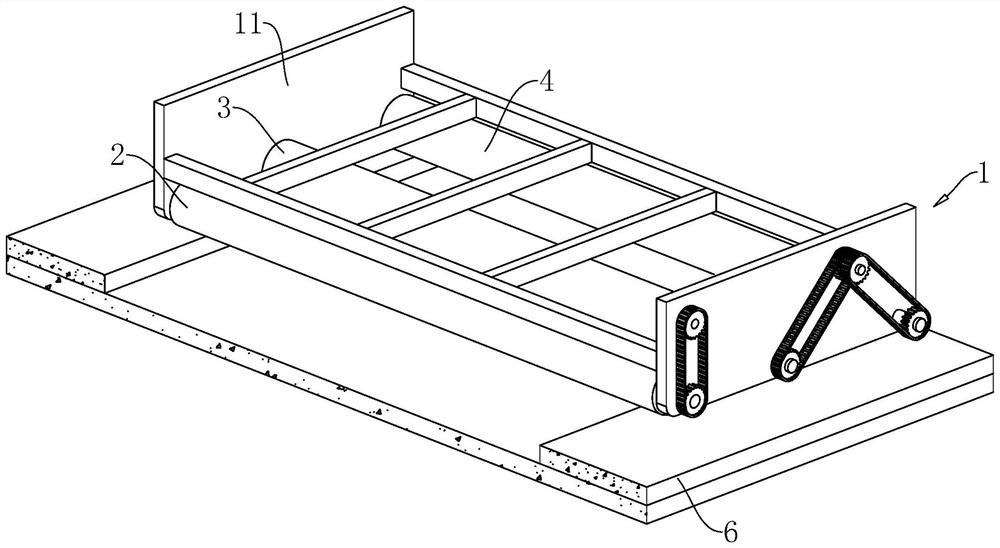

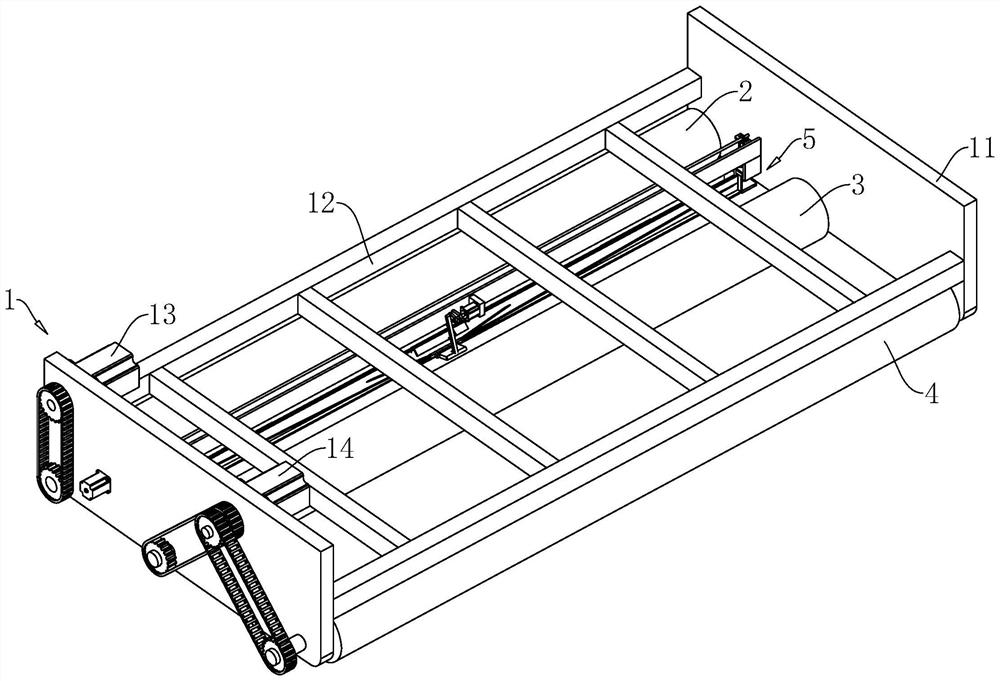

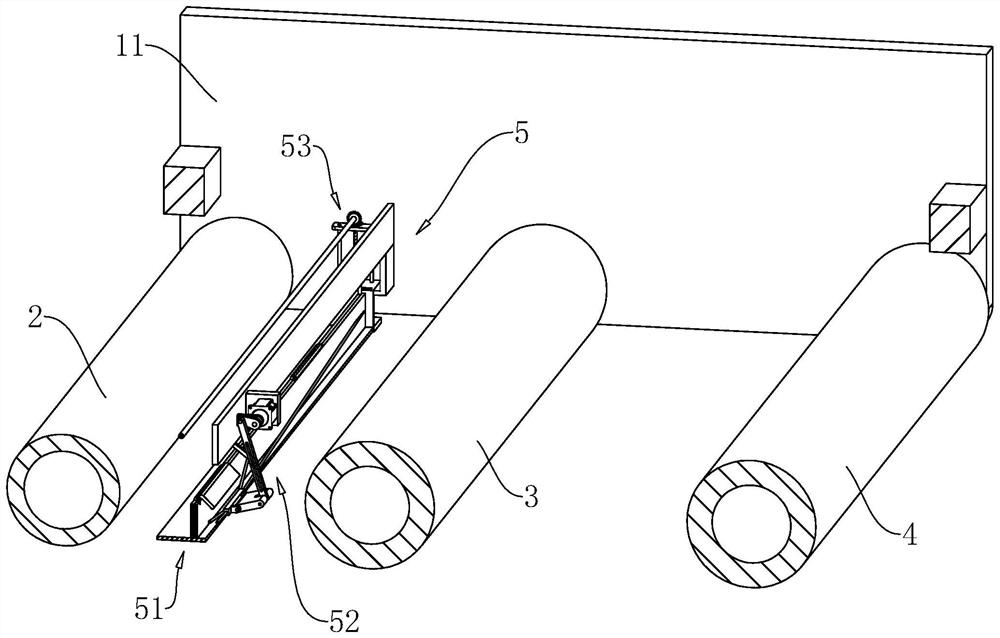

[0045] refer to figure 2 , a device for bridge deck construction includes a frame body 1, the frame body 1 includes two fixed plates 11 arranged horizontally at intervals, and two beams 12 are fixed between the two fixed plates 11. A first roller shaft 2 , a second roller shaft 3 and a third roller shaft 4 are sequentially arranged at intervals along the horizontal direction between the two fixing plates 11 .

[0046] refer to figure 2 , wherein a first motor 13 is installed on one of the fixed plates 11, and is used to drive the first roller shaft 2 to rotate alone, and a second motor 14 is also installed on the same fixed plate 11, and the second motor 14 is used to jointly drive the second roller shaft 3 and the third roller shaft 4 rotate, the third roller shaft 4 provides po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com