Design method of large-curvature cable-membrane structure

A design method, a technology of large curvature, applied in design optimization/simulation, using stable tension/pressure test material strength, instruments, etc., can solve the problems of cable-membrane structure temperature performance influence, change of body size, plastic deformation, etc. Achieve the effect of improving the overall stress stability, speeding up the construction speed, and reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A design method for a large-curvature cable-membrane structure, comprising the following steps:

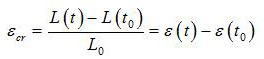

[0030] (1) Perform performance analysis on the membrane materials to be used in the large-curvature cable-membrane structure to determine the membrane materials to be used; performance analysis includes membrane tensile performance analysis and membrane creep performance analysis;

[0031] (2) Use ANSYS software to conduct form-finding analysis on the large-curvature cable-membrane structure, and select the SHELL41 unit to simulate the membrane material in the cable-membrane structure;

[0032] (3) By analyzing the stress of membrane materials with different thicknesses under the action of wind load, select membrane materials with appropriate thickness;

[0033] (4) Optimizing the reinforcement cable net in the large-curvature cable-membrane structure; specifically including determining the structural system, selection and optimization of the cable net layout scheme, and se...

Embodiment 2

[0046] A design method for a large-curvature cable-membrane structure, comprising the following steps:

[0047] (1) Perform performance analysis on the membrane materials to be used in the large-curvature cable-membrane structure to determine the membrane materials to be used; performance analysis includes membrane tensile performance analysis and membrane creep performance analysis;

[0048] (2) Use ANSYS software to conduct form-finding analysis on the large-curvature cable-membrane structure, and select the SHELL41 unit to simulate the membrane material in the cable-membrane structure;

[0049] (3) By analyzing the stress of membrane materials with different thicknesses under the action of wind load, select membrane materials with appropriate thickness;

[0050] (4) Optimizing the reinforcement cable net in the large-curvature cable-membrane structure; specifically including the determination of the structural system, selection and optimization of the cable net layout schem...

Embodiment 3

[0063] A design method for a large-curvature cable-membrane structure, comprising the following steps:

[0064] (1) Perform performance analysis on the membrane materials to be used in the large-curvature cable-membrane structure to determine the membrane materials to be used; performance analysis includes membrane tensile performance analysis and membrane creep performance analysis;

[0065] (2) Use ANSYS software to conduct form-finding analysis on the large-curvature cable-membrane structure, and select the SHELL41 unit to simulate the membrane material in the cable-membrane structure;

[0066] (3) By analyzing the stress of membrane materials with different thicknesses under the action of wind load, select membrane materials with appropriate thickness;

[0067] (4) Optimizing the reinforcement cable net in the large-curvature cable-membrane structure; specifically including the determination of the structural system, selection and optimization of the cable net layout scheme,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com