Self-adjusting building embedded section and embedding method thereof

A self-adjusting and pre-embedded technology, which is applied in the direction of vibration suppression adjustment, cable installation device, electrical components, etc., can solve the problems of easy displacement of pre-embedded joints, instability of pre-embedded joints, inconvenient maintenance, etc., and achieve novel splicing structure Ingenious, reducing the probability of maintenance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

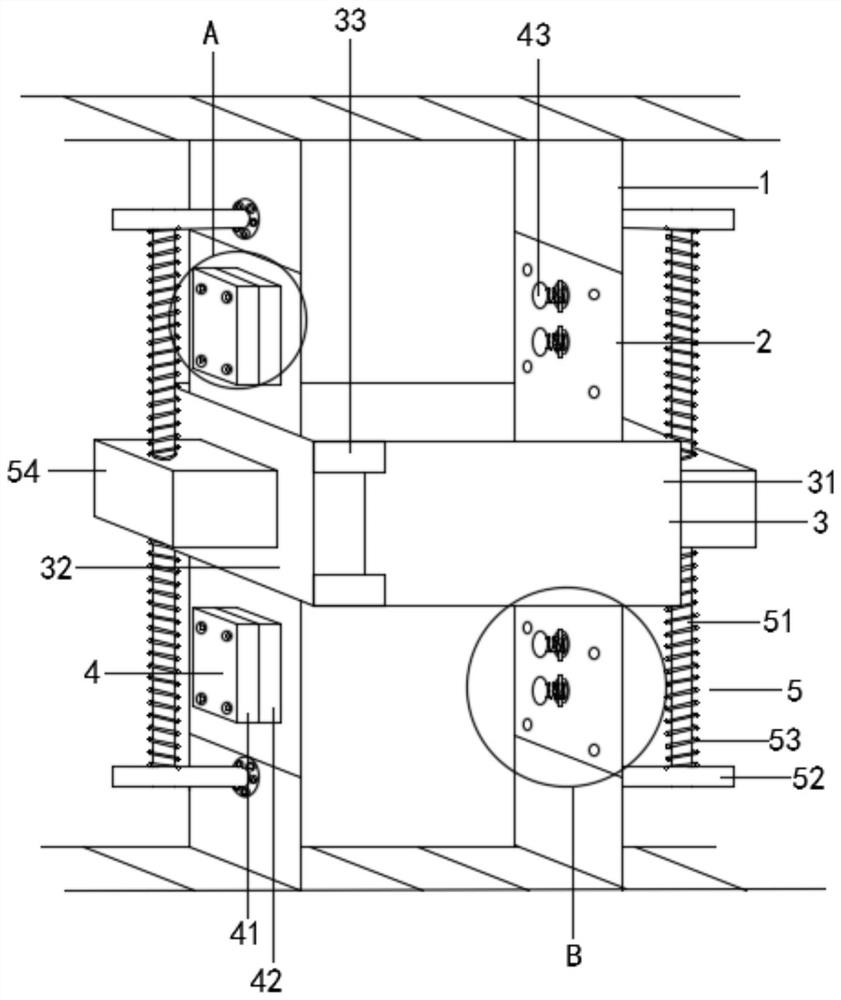

[0047] Refer to the attached Figure 1-9 , a self-adjusting built-in construction joint in this embodiment, comprising a bridge frame 1, a second through hole 11 is opened on the bridge frame 1, and also includes: a butt plate 2 detachably connected to the bridge frame 1; and

[0048] The pre-embedded section 3 of the detachable connection bridge;

[0049] The bridge frame 1 and the docking plate 2 are connected through the first connection assembly 4, and the bridge frame 1 and the embedded joint 3 are connected through the second connection assembly 5 or the fourth connection assembly 6;

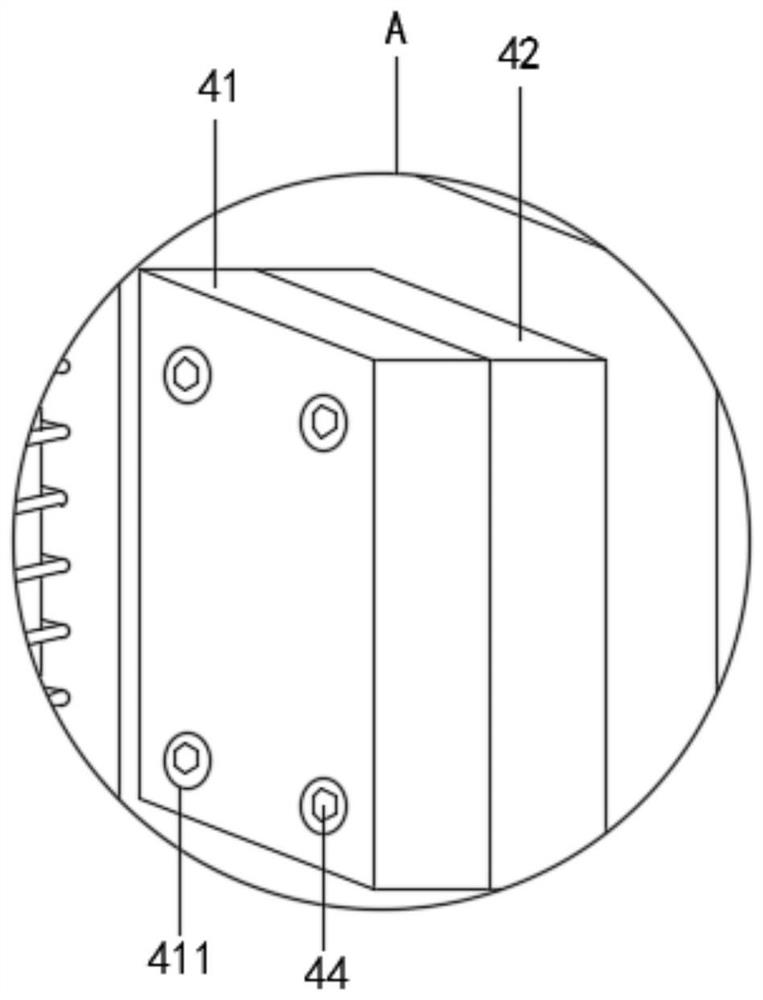

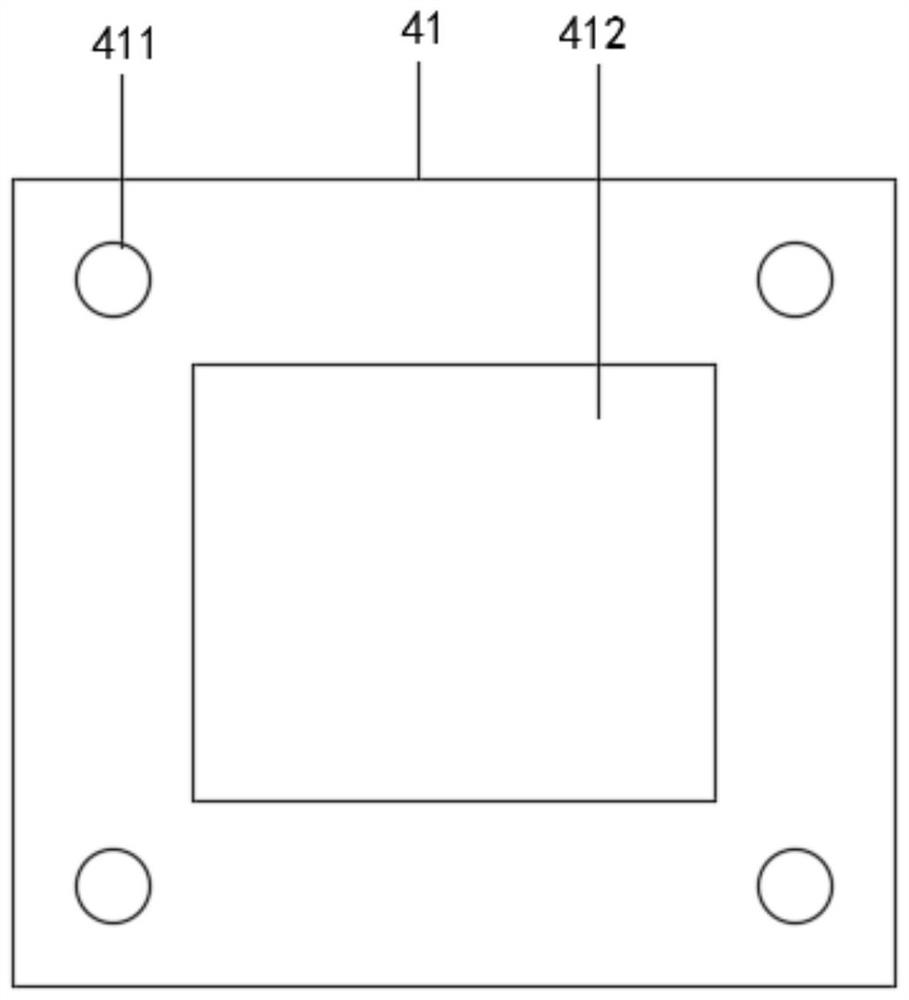

[0050] The first connection assembly 4 includes a first square plate 41, the first square plate 41 is connected to the second square plate 42, and the second square plate 42 is provided with a first through hole 422, a first rectangular through hole 423 and a rectangular groove 424, the inner wall of the first through hole 422 is inserted into the plug pin 43;

[0051] The latch 43 inclu...

Embodiment 2

[0067] Refer to the attached Figure 10-11 , the difference from Embodiment 1 is that: the bridge frame 1 and the embedded joint 3 are connected through the fourth connection assembly 6;

[0068] The fourth connection assembly 6 includes a sliding seat 61, the inner wall of the embedded joint 3 is fixedly installed with a sliding seat 61, and the sliding seat 61 is provided with a T-shaped chute 611, and the inner wall of the T-shaped chute 611 is slidably connected to the T T-shaped slider 21, one end of the T-shaped slider 21 is fixedly connected to the butt plate 2, the two ends of the slider 61 are fixedly connected to the cover 62 by bolts, and the T-shaped chute 611 is provided with a fourth spring 63 , one end of the fourth spring 63 is fixedly connected to the cover 62, and the other end of the fourth spring 63 is fixedly connected to the T-shaped slider 21;

[0069] The specific implementation scenarios are:

[0070] When using the present invention, the first splic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com