Efficient iron ore concentrate and tailing slurry water recovery device and method

A return water device and technology for iron ore concentrates, applied in separation methods, chemical instruments and methods, filtration circuits, etc., can solve problems such as unfavorable equipment maintenance, increase the cost of iron ore grinding, and large cost investment, and reduce the return rate. The cost of water collection, the improvement of return water efficiency, and the effect of short return water distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All features disclosed in this specification, or the steps in all methods or processes disclosed, in addition to the features and / or steps of mutual rejection, can be combined in any manner.

[0023] Any feature disclosed in this specification (including any additional claims, abstract), unless otherwise specified, it can be replaced by other alternative or similar purposes. That is, unless specifically described, each feature is only an example of a series of equivalents or similar features.

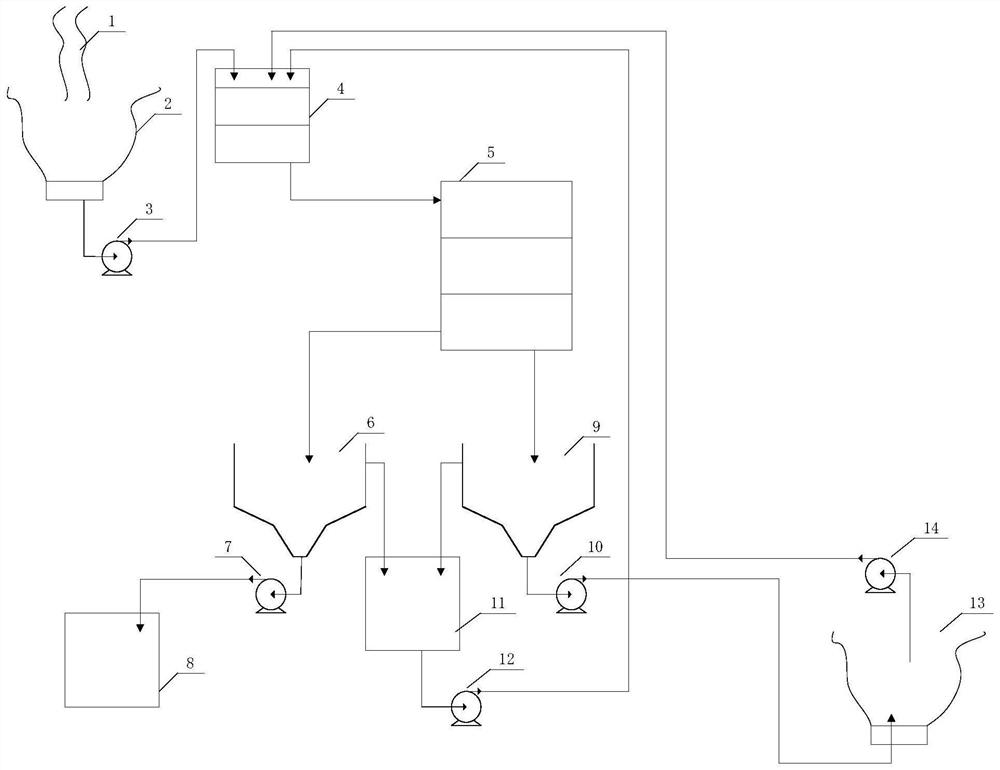

[0024] The present invention discloses a highly efficient iron ore, tail mine slurry returning device, including a high-level storage pool 4, a granulation shop 5 and a concentrated pool disposed from top to bottom; the concentration pool includes concentrate concentration pools 6 and tail mine concentration tank 9; the high-level reservoir 4 connects to the workshop 5, the mouse workshop 5, respectively, in line with concentrate concentration tank 6 and tail concentration tank 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com