Energy-saving type mesh belt quenching furnace

A quenching furnace, energy-saving technology, applied in the production field of quenching furnace, can solve the problems of energy waste, poor heat preservation effect of quenching furnace, etc., and achieve the effect of improving heat preservation effect and reducing thermal bridge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

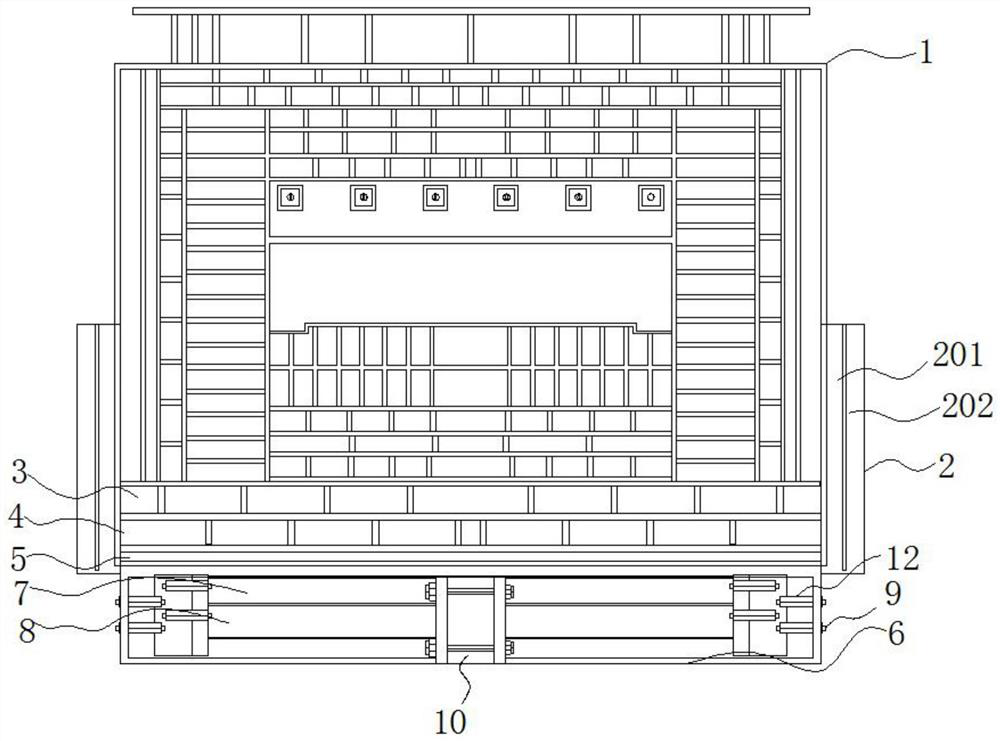

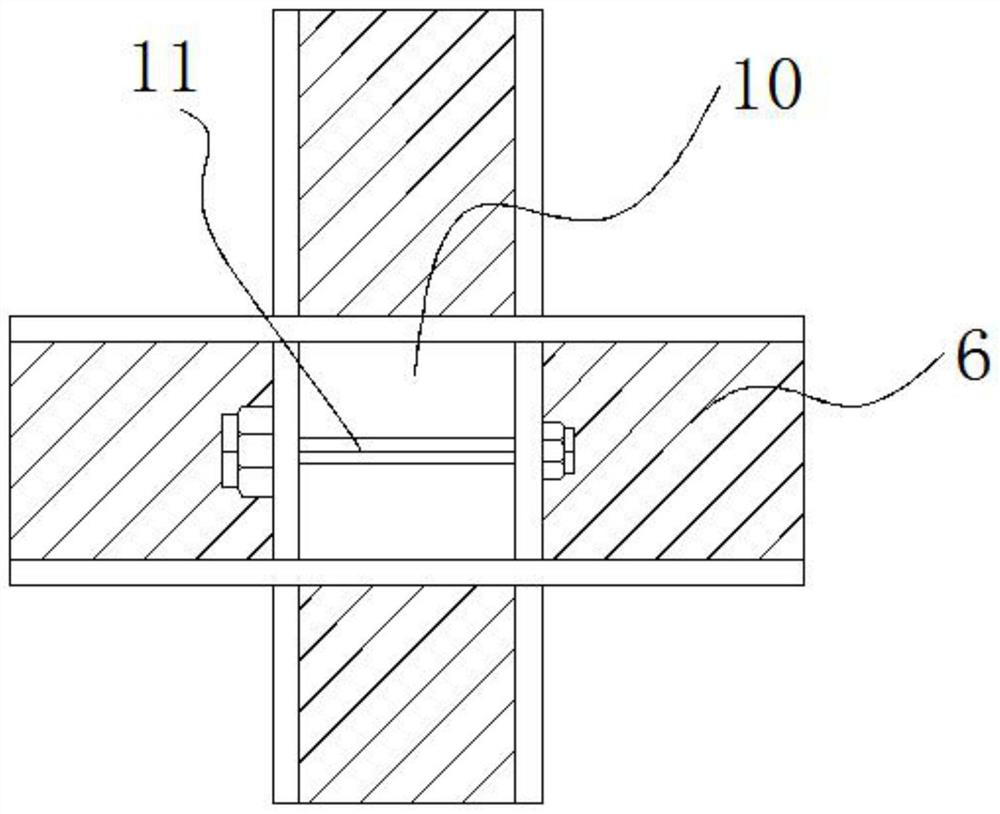

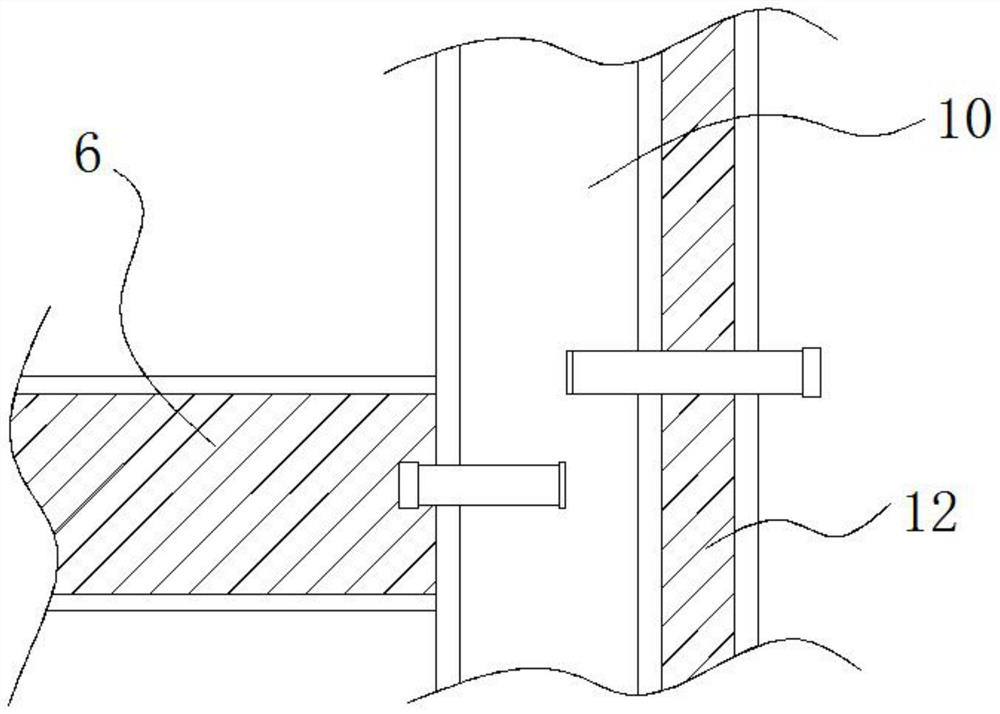

[0030] see figure 1 , the present invention provides a technical solution: an energy-saving mesh belt quenching furnace, comprising: a main body 1; a heat preservation mechanism 2, the heat preservation mechanism 2 is arranged at both ends outside the main body 1, and the bottom inside the main body 1 is provided with a first furnace bottom Insulation layer 3, the second furnace bottom insulation layer 4 is installed on the lower end of the first furnace bottom insulation layer 3, the third furnace bottom insulation layer 5 is installed on the lower end of the second furnace bottom insulation layer 4, the first furnace bottom insulation layer 3, The thickness of the second furnace bottom insulation layer 4 and the third furnace bottom insulation layer 5 is 278mm in total, and the compressive coefficients of the first furnace bottom insulation layer 3, the second furnace bottom insulation layer 4 and the third furnace bottom insulation layer 5 are sequentially Decreasing, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com