Installation type high-pile wharf structure and construction method

A technology of high-pile wharf and construction method, which is applied in infrastructure engineering, water conservancy engineering, sea area engineering, etc., can solve the problems of low construction efficiency and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

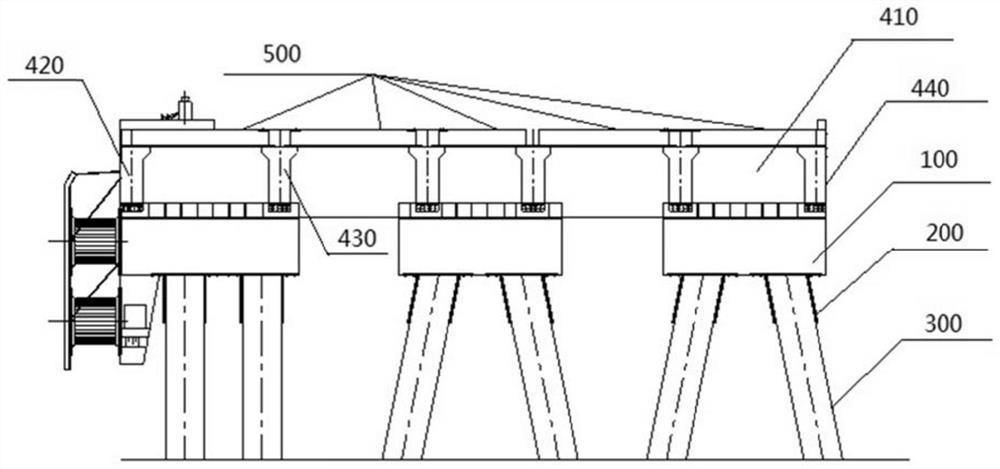

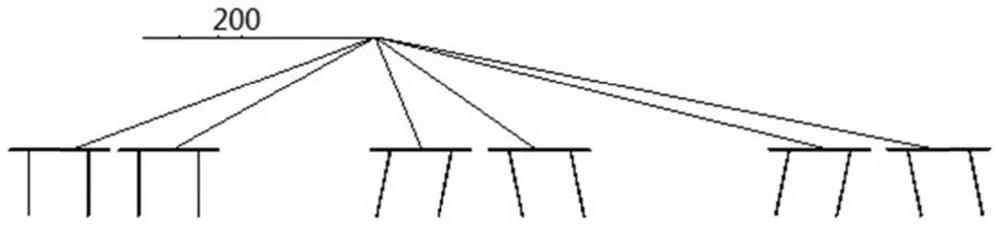

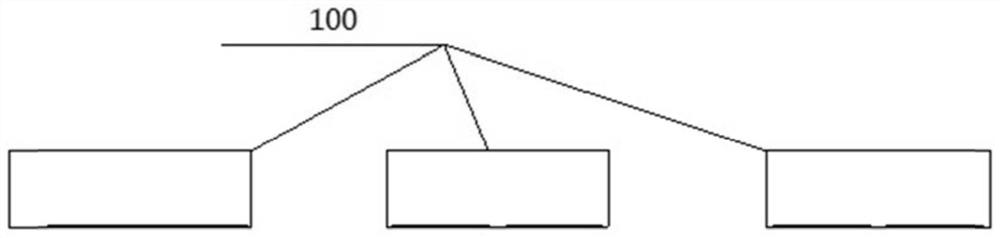

[0033] For the installed high-piled wharf structure provided by this scheme, see figure 1 , which is composed of a prefabricated plate 500 with a steel structure, a beam member, a pile cap 100, a transfer steel 200, a pile foundation 300 and connecting steel plates (not marked in the figure). The size of each prefabricated component can be determined according to the actual situation.

[0034] Wherein, the prefabricated slab 500 with steel structure is prefabricated by pre-embedding the connecting steel plate in the concrete when the prefabricated slab is prefabricated. As for the beam member, the approach of the pile cap 100 is similar to that of the slab, in that the steel plate is pre-embedded in the concrete.

[0035] The size of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com