Erecting method of fair-faced concrete sheet wall arc formwork

A technology of fair-faced concrete and formwork, which is applied in the direction of formwork/formwork/work frame, connection of formwork/formwork/work frame, and on-site preparation of building components, etc. Dimensional member support and calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further illustrated below by specific examples.

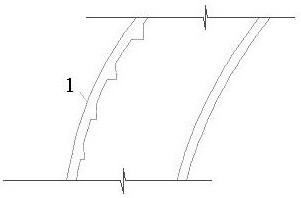

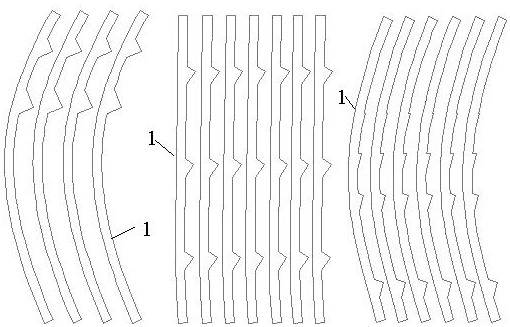

[0014] Such as figure 1 and figure 2 Shown, a kind of fair-faced concrete sheet wall circular arc formwork erecting method comprises

[0015] Step 1. Embody the fair-faced concrete circular arc section back flute 1 on the CAD drawing according to the model, and segment according to the drawing;

[0016] Step 2. The full-automatic engraving machine carries out the special-shaped formwork back corrugation processing and production, including three 18mm thick back corrugations combined into a 54mm thick back corrugation as the wall beam bottom to reinforce the secondary keel, and the curved wooden back corrugated outer arc surface In the part with a large arc, the arc shape is canceled and changed to a flat trapezoidal opening perpendicular to the inner arc of the back corrugated surface and the ground, so as to ensure that the double C-shaped steel profiles of the transverse main keel have suffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com