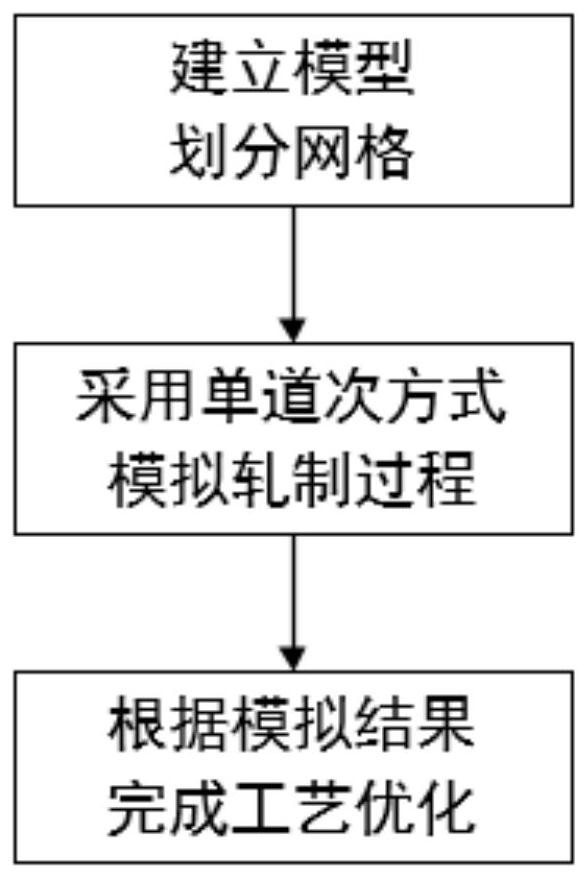

Flat-bulb steel rolling process optimization method based on finite element simulation

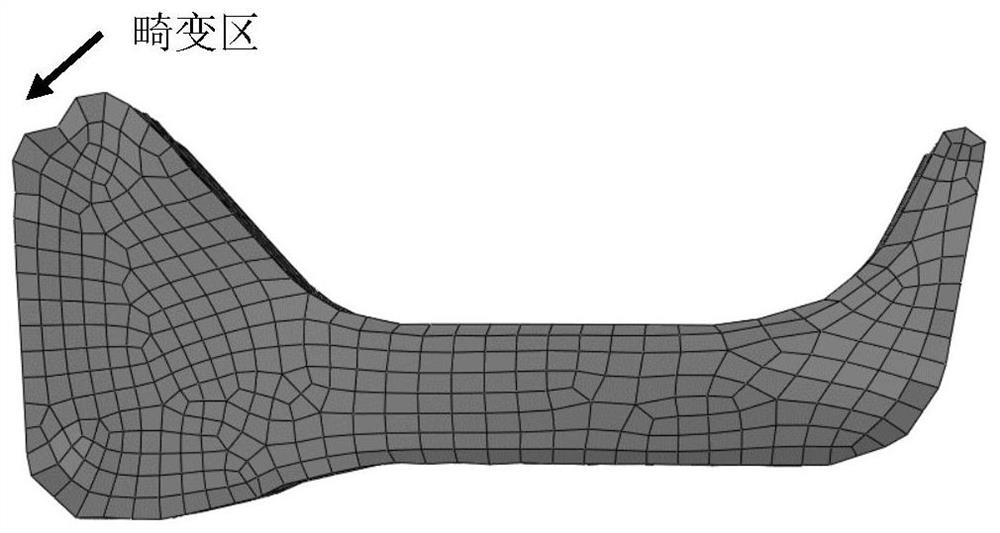

A process optimization and finite element technology, applied in metal rolling, design optimization/simulation, CAD numerical modeling, etc., can solve the problem of unsuitable cross-section shape, unfavorable multi-pass rolling simulation, mesh re-division and reconstruction and other problems. The division method is cumbersome and other problems, so as to ensure the accuracy of calculation, shorten the simulation operation time, and avoid serious distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Taking the rolling of HP370*13 spherical flat steel with a section size of 280mm*165mm as an example, in order to realize the flexible and controlled rolling of the rolling process of spherical flat steel, the finite element simulation method in the present invention is used for calculation, and the spherical flat steel is calculated according to the calculation results. The rolling process of flat steel is optimized:

[0085] Make full use of the advantages of each model to simulate a complex multi-pass large deformation process in stages:

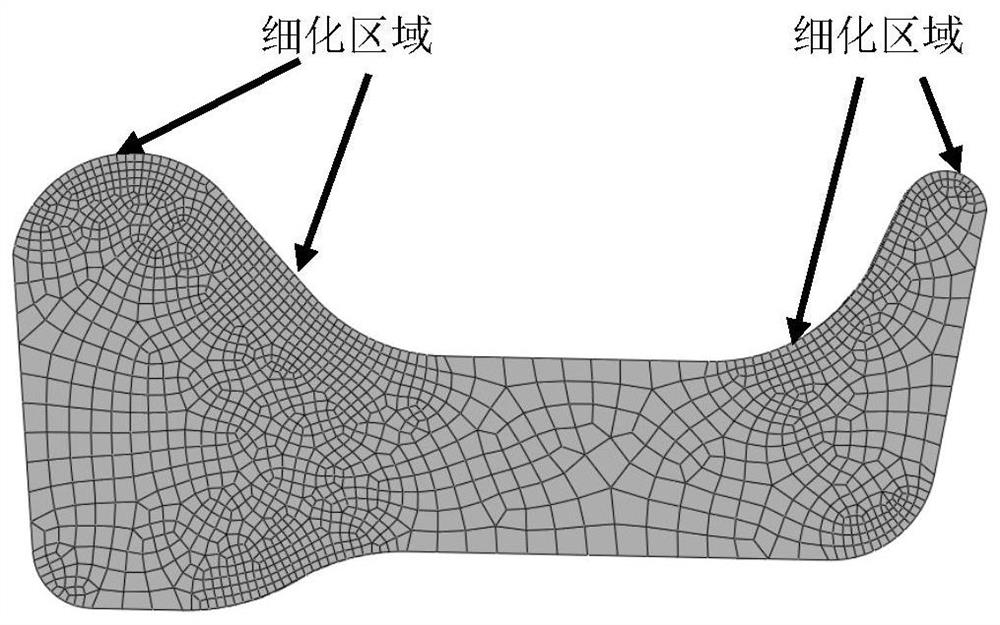

[0086] 1) Use grid topology and grid seeds to realize the grid structure of complex cross-section blanks in each pass, such as figure 2 shown. The number of cross-sectional meshes N after local refinement is 1593, and the number of meshes before local refinement is N 0 384, satisfying N=(2~5)N 0 requirements. The cross-sectional area of the billet in this pass is 21237mm 2 , the pass area reduction rate is 21%, and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com