Synthesis process of novel silicon paste with high defoaming performance

A synthesis process and defoaming technology, applied in the directions of foam dispersion/prevention, separation method, liquid degassing, etc., can solve the problems of inability to meet the performance requirements of users, increase the production input of producers, and the preparation method is cumbersome, etc. The effect of high controllability, stable product and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

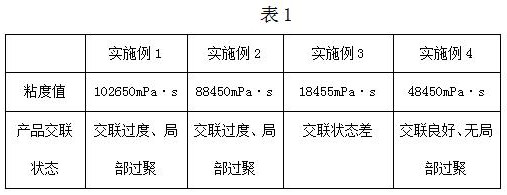

Examples

Embodiment 1

[0026] The invention provides a synthesis process of a new type of silicone paste with high defoaming performance, which includes the following raw materials in parts by weight: 350-400 parts of silicone oil, 150-200 parts of hydrogen-containing silicone oil (hydrogen content 0.18%), vinyl silicone oil (vinyl content 0.8%) 100-150 parts, MQ resin 50-70 parts, white carbon black 20-40 parts, chloroplatinic acid-isopropanol solution (0.3%wt) 0.02-0.06 parts, post-treatment agent Cat. 2 20-30 parts, the specific synthesis steps are as follows:

[0027] S1. Material dispersion: put 380 parts of silicone oil, 132 parts of hydrogen-containing silicone oil (0.18% hydrogen content), 120 parts of vinyl silicone oil (0.8% vinyl content), 60 parts of MQ resin and 32 parts of white carbon black into the reactor Disperse at 400rpm for 15min;

[0028] S2. Heat preservation reaction: After step S1 is completed, slow down to 130rpm and stir and heat up. Add 0.04 parts of chloroplatinic acid-...

Embodiment 2

[0031] The invention provides a synthesis process of a new type of silicone paste with high defoaming performance, which includes the following raw materials in parts by weight: 350-400 parts of silicone oil, 150-200 parts of hydrogen-containing silicone oil (hydrogen content 0.18%), vinyl silicone oil (vinyl content 0.8%) 100-150 parts, MQ resin 50-70 parts, white carbon black 20-40 parts, chloroplatinic acid-isopropanol solution (0.3%wt) 0.02-0.06 parts, post-treatment agent Cat. 2 20-30 parts, the specific synthesis steps are as follows:

[0032] S1. Material dispersion: put 380 parts of silicone oil, 132 parts of hydrogen-containing silicone oil (0.18% hydrogen content), 120 parts of vinyl silicone oil (0.8% vinyl content), 60 parts of MQ resin and 32 parts of white carbon black into the reactor Disperse at 400rpm for 15min;

[0033] S2. One round of heat preservation reaction: After step S1 is completed, slow down to 130rpm and stir and heat up, add 0.025 parts of chloro...

Embodiment 3

[0037] The invention provides a synthesis process of a new type of silicone paste with high defoaming performance, which includes the following raw materials in parts by weight: 350-400 parts of silicone oil, 150-200 parts of hydrogen-containing silicone oil (hydrogen content 0.18%), vinyl silicone oil (vinyl content 0.8%) 100-150 parts, MQ resin 50-70 parts, white carbon black 20-40 parts, chloroplatinic acid-isopropanol solution (0.3%wt) 0.02-0.06 parts, post-treatment agent Cat. 2 20-30 parts, the specific synthesis steps are as follows:

[0038] S1. Material dispersion: put 380 parts of silicone oil, 132 parts of hydrogen-containing silicone oil (0.18% hydrogen content), 120 parts of vinyl silicone oil (0.8% vinyl content), 60 parts of MQ resin and 32 parts of white carbon black into the reactor Disperse at 400rpm for 15min;

[0039] S2. One round of heat preservation reaction: After step S1 is completed, slow down to 130rpm and stir and heat up, add 0.02 parts of chlorop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com