Low-concentration gas efficient mixing device and method

A low-concentration gas, high-efficiency technology, applied in the field of pneumatic blending, can solve the problems of low blending effect, low blending pressure loss, and inability to effectively adjust the blending strength of the blending device, so as to reduce the length of the mixing section and reduce the Investment cost, the effect of improving the installation space environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

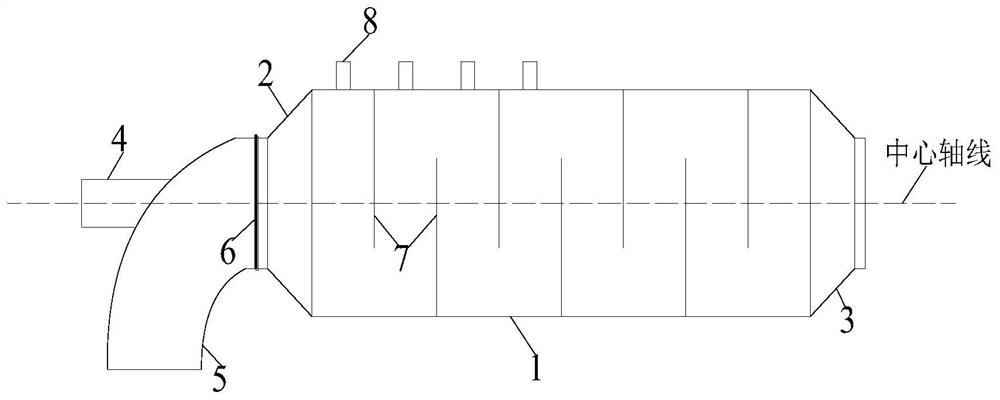

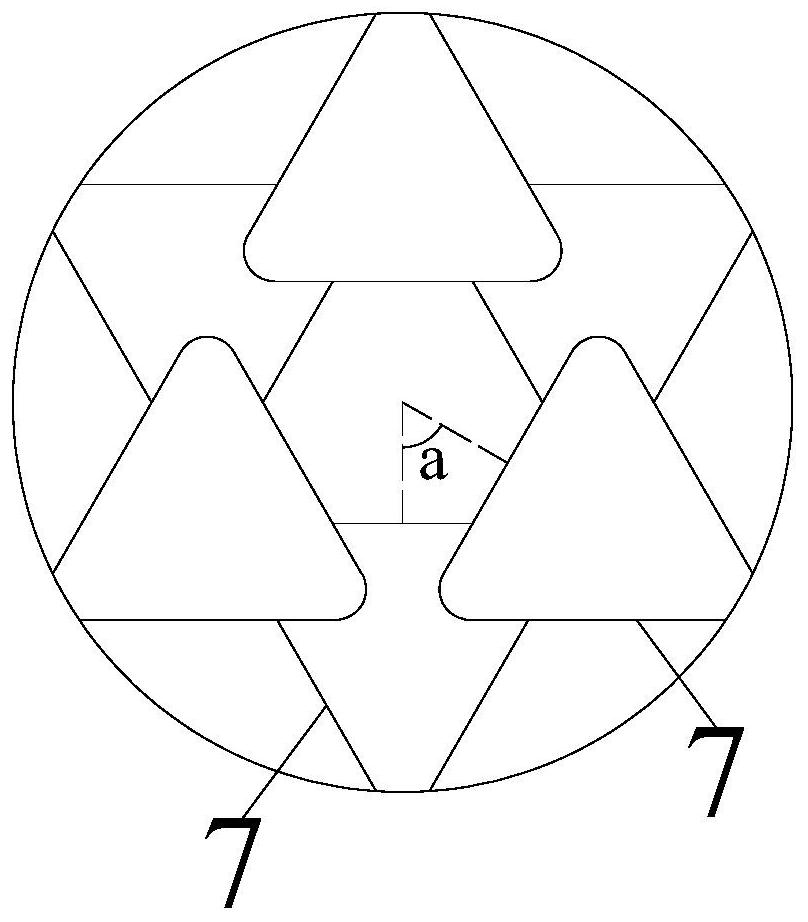

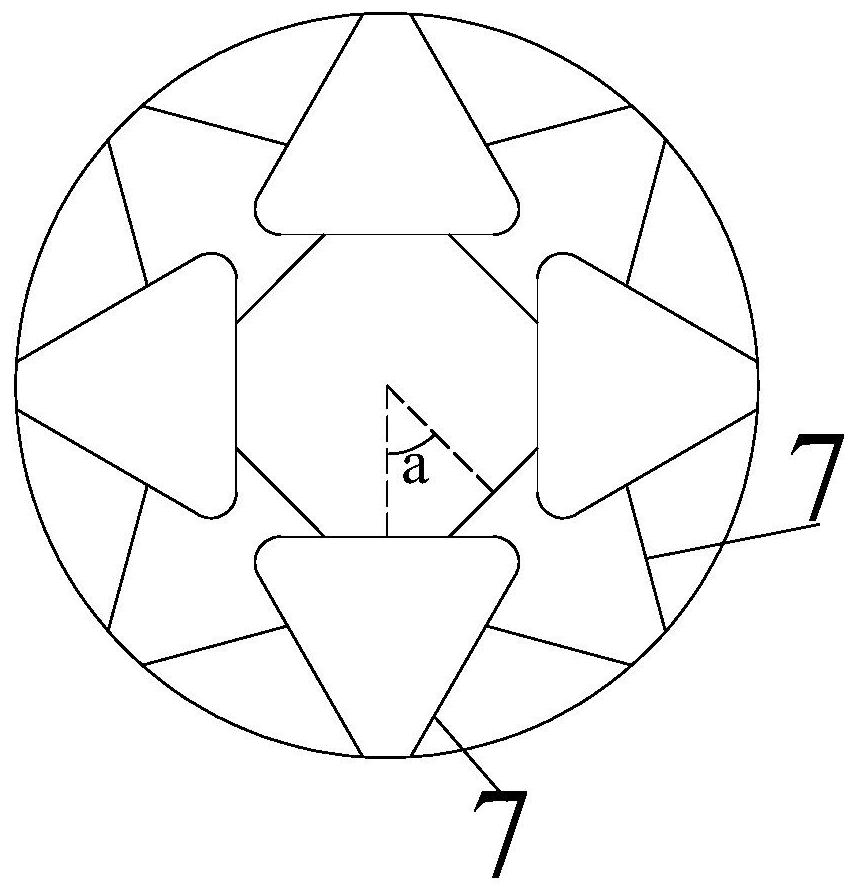

[0029] see figure 1 , in this embodiment, a low-concentration gas high-efficiency blending device includes: a mixing chamber 1, an air inlet pipe mouth 2, an air outlet pipe mouth 3, a low-concentration gas air inlet pipe 4, an air inlet pipe 5, a flange 6, a disturber Flow device 7, turbulence inlet port 8 and spoiler 9, the mixing chamber 1 is a cylindrical cavity body structure, the inlet end of the mixing chamber 1 is connected with an inlet nozzle 2, and the inlet nozzle 2 flows along the gas The direction is the expansion pipe, the outlet end of the mixing chamber 1 is connected with the outlet pipe port 3, and the air outlet pipe port 3 is a contraction pipe along the gas flow direction, and the air inlet pipe 5 is connected with the inlet end of the air inlet pipe port 2 through the flange 6, And the air intake direction of the air intake pipe 5 is perpendicular to the central axis of the mixing chamber 1, and the air intake pipe 5 is also connected to the low-concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com