Integrated automobile wheel wrench forming method

A forming method and technology of automobile wheels, which are applied in the field of integral automobile wheel wrench forming, can solve problems such as cracking, deformation, and insufficient toughness of wheel wrenches, and achieve the effects of improving service life and increasing fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

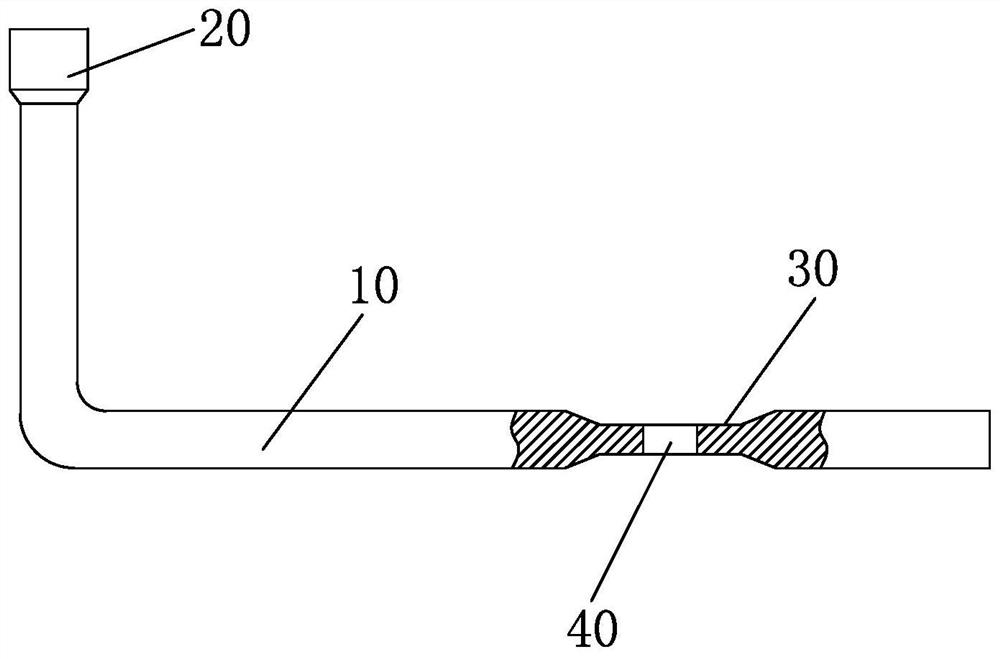

Image

Examples

Embodiment 1

[0025] The tensile strength of No. 45 steel is 600MPa, the yield strength is 355MPa, the hot rolling hardness is 229HBS, and the annealing hardness is 197HBS. Because it contains less harmful impurities such as sulfur and phosphorus, the quality is higher, and its strength, plasticity and toughness are higher than those of carbon structural steel. Good, with good comprehensive mechanical properties, it is an ideal material for making automobile wheel wrenches.

[0026] The integrated automobile wheel wrench forming method, the automobile wheel wrench adopts No. 45 steel, and the forming method includes the following steps:

[0027] S1, using a cylindrical bar as the blank, blanking according to the designed length to obtain a piece of rough blank;

[0028] S2, carrying out the plane chamfering of the end face by turning the rough material provided in the step S1;

[0029] S3, put the blank that has passed the step of S2 into the mold of the forging machine vertically, the jaw...

Embodiment 2

[0045] The integral automobile wheel wrench forming method comprises the following steps:

[0046] S1, using a cylindrical bar as the blank, blanking according to the designed length to obtain a piece of rough blank;

[0047] S2, carrying out the plane chamfering of the end face by turning the rough material provided in the step S1;

[0048] S3, put the blank that has passed the step of S2 into the mold of the forging machine vertically, the jaw plate of the forging machine clamps the top-to-bottom third of the blank, and heats the blank close to the top by means of electric heating One part is heated to 820°C;

[0049] S4, the pier head of the forging machine goes down, and the mold forms an inner hexagonal hole on the top of the blank, and expands the hole diameter to the specified size;

[0050] S5, using air cooling to naturally cool the blank to 25°C;

[0051] S6, tempering the part from the top of the blank to the bending position, the tempering temperature is 650°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com