Method for preventing resin from tackifying and generating large particles during polymerization reaction

A polymerization reaction, large particle technology, applied in the field of resin processing, to achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

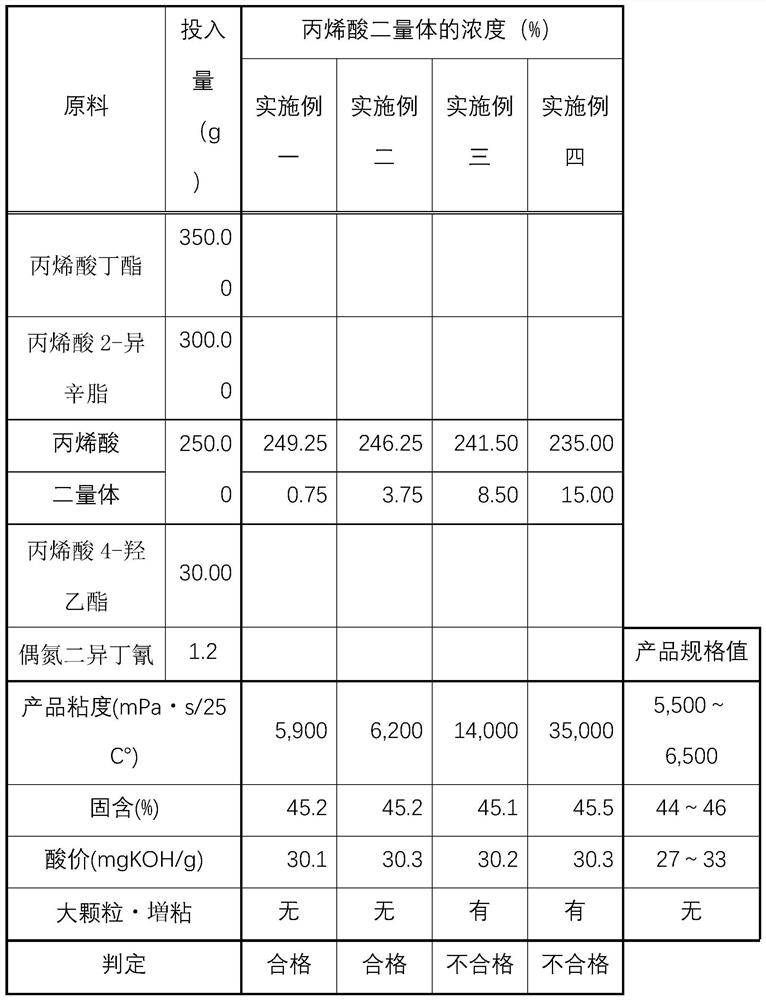

Embodiment 1

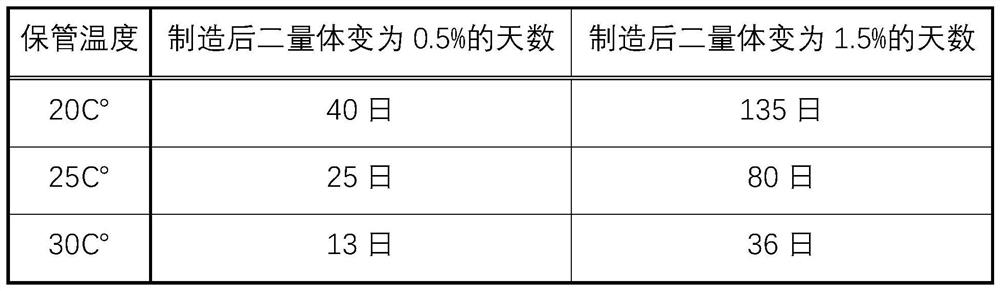

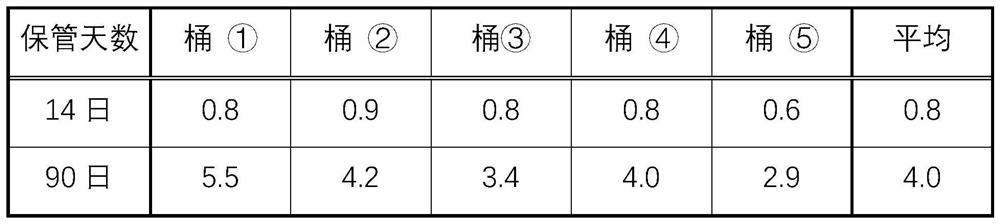

[0012] Put the following components by weight: 350g of butyl acrylate, 300g of 2-isooctyl acrylate, 250g of acrylic acid, 30g of 4-hydroxyethyl acrylate, and 1.2g of azobisisobutylcyanide into the mixing equipment, stir and mix evenly, that is Yes; the binary content of the above-mentioned acrylic acid is 0.75g, the storage temperature of acrylic acid is 25 degrees Celsius, and the storage period is within 80 days after the production of acrylic acid.

Embodiment 2

[0014] Put the following components by weight: 350g of butyl acrylate, 300g of 2-isooctyl acrylate, 250g of acrylic acid binary body, 30g of 4-hydroxyethyl acrylate, and 1.2g of azobisisobutylcyanide, put them into the mixing equipment, stir and mix Uniform, enough; the binary content in the above-mentioned acrylic acid is 3.75g, the storage temperature of acrylic acid is 25 degrees centigrade, and the storage period is within 80 days after the production of acrylic acid.

Embodiment 3

[0016] Put the following components by weight: 350g of butyl acrylate, 300g of 2-isooctyl acrylate, 250g of acrylic acid binary body, 30g of 4-hydroxyethyl acrylate, and 1.2g of azobisisobutylcyanide, put them into the mixing equipment, stir and mix Uniform, that is enough; the binary content in the above-mentioned acrylic acid is 8.5g, the storage temperature of acrylic acid is 25 degrees centigrade, and the storage period is within 80 days after the production of acrylic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com