Cooling-to-energy aerospace engine

An engine and energy technology, applied in engine components, engine cooling, machine/engine, etc., can solve the problem that the engine is difficult to greatly increase the working temperature of the nozzle in the energy chamber, it is difficult to ensure the strength of the engine structure and material, and the high-energy working fluid cannot be used. and other problems, to achieve the effect of reducing the difficulty of structure and manipulation, simple and easy storage and addition, and ensuring the strength of structure and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

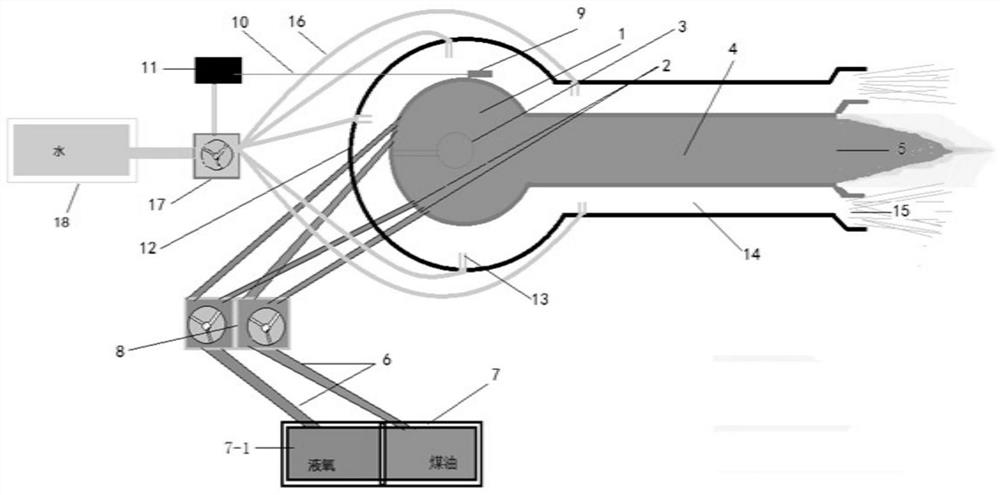

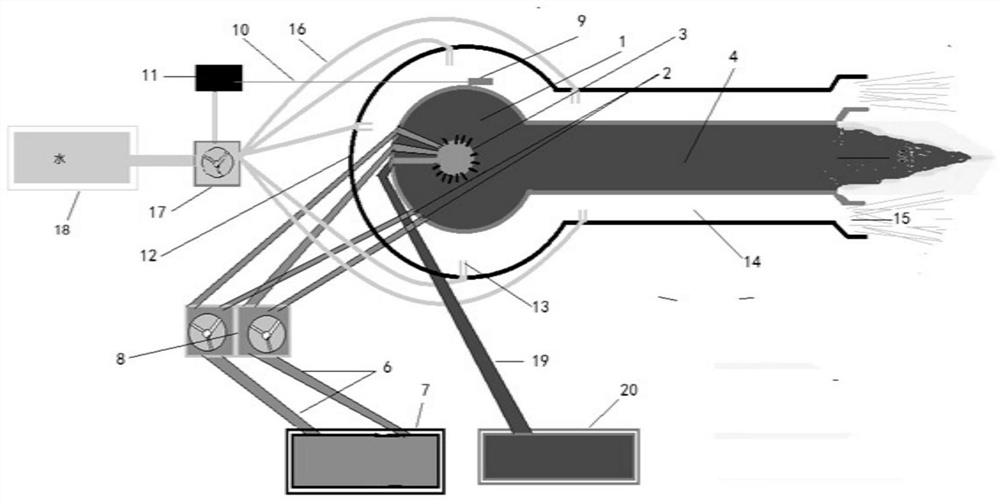

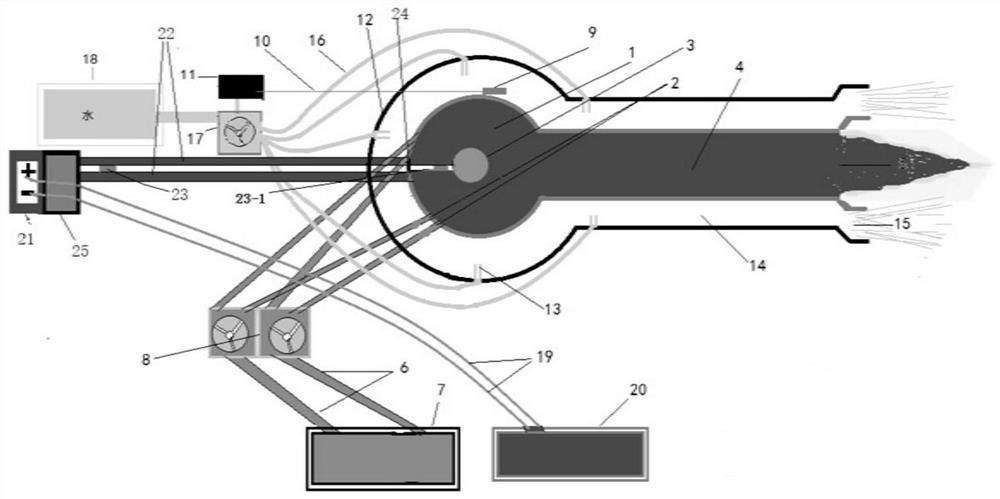

[0020] Such as figure 1 Shown: be the structural representation of embodiment 1 of the present invention, a kind of cooling transfer energy aerospace engine, its energy chamber (combustion chamber) 1, has the aperture 2 of uniform distribution, the aperture 2 other ends and working fluid conduit (propulsion) agent) 6 in communication, the working fluid conduit 6 is in communication with the working fluid compression regulator 8 and the working fluid constant temperature storage tank 7 (including the liquid oxygen storage tank 7-1); the energy chamber (combustion chamber) 1 is in communication with the inner nozzle 4, and the inner The corresponding inner nozzle 5 of nozzle pipe 4 ejects energy to do work; Ignition or energy launching device 3 is installed in the energy chamber (combustion chamber) 1, just an ignition device; the outer wall of energy chamber (combustion chamber) 1 and the inner nozzle pipe 4 The outer wall has a temperature detector 9 connected to the thermosta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap