A periodic microstructure noise reduction device, noise suppression test system and method

A noise suppression and testing system technology, applied in the field of aerodynamic noise reduction, can solve the problems of lack of engineering practical noise reduction measures, poor noise reduction effect of noise reduction structure, poor engineering practicability, etc., and achieve strong engineering implementability , Reliable noise reduction effect, and wide range of applicable speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment proposes a new periodic microstructure noise reduction device for noise suppression, and conducts multi-parameter noise reduction effect research on the periodic microstructure noise reduction device through a special acoustic wind tunnel, analyzes and compares the added The wind noise spectrum and A-weighted total sound pressure level before and after noise suppression measures provide reliable data support and suggestions for cylindrical blunt body noise reduction measures.

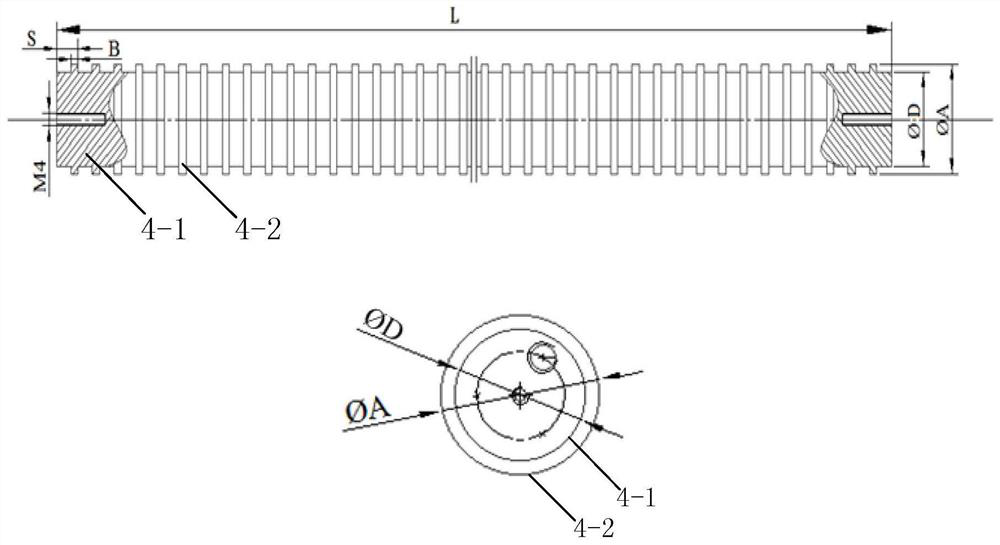

[0047] Specific as figure 1 As shown, the periodic microstructure noise reduction device of this embodiment includes a reference cylinder 4-1, on which a radial protruding structure 4-2 is periodically arranged in the axial direction on the reference cylinder 4-1, wherein the reference cylinder The diameter of 4-1 is D, the length of the reference cylinder 4-1 is L; the outer diameter of the radial protrusion structure 4-2 is A, the setting period is S, and the thickness is B.

[0...

Embodiment 2

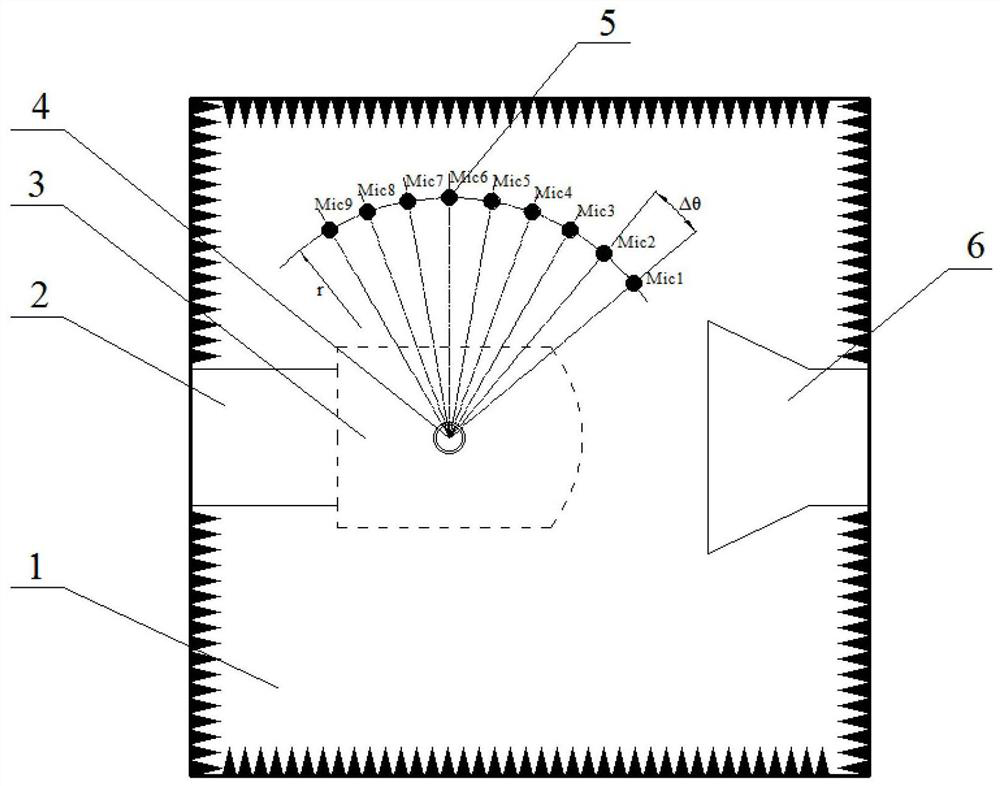

[0050] This embodiment proposes a noise suppression test system for researching the noise reduction performance of the periodic microstructure noise reduction device proposed in the above embodiment 1 under different structural types, specifically as figure 2 As shown, the test device of this embodiment includes a wind tunnel 1 , a noise sensor 5 and a model test piece 4 .

[0051] The model test piece 4 of this embodiment is the periodic microstructure noise reduction device proposed in the above-mentioned embodiment 1.

[0052] Both the model test piece 4 and the noise sensor 5 of this embodiment are installed in the wind tunnel 1 .

[0053] The wind tunnel 1 of this embodiment adopts a 0.55m×0.4m acoustic anechoic wind tunnel 1, and connecting devices are respectively arranged on both sides of the nozzle 2 of the wind tunnel 1. Installed between the two side plates 3. In this embodiment, two side plates are arranged at the flange of the nozzle 2, one is used to fix the m...

Embodiment 3

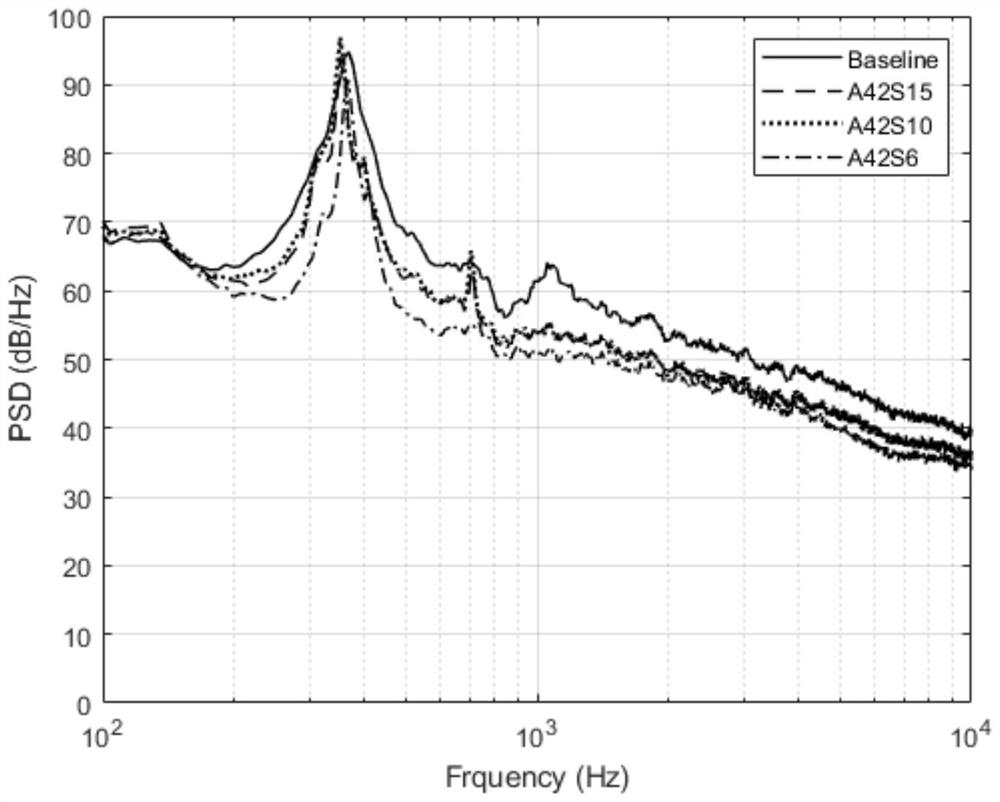

[0058] In this embodiment, the test system proposed in the above-mentioned embodiment 2 is used for testing and analysis, and the specific process includes:

[0059] Each of the pre-prepared model test pieces in different parameter states is tested under different test conditions to obtain noise test data;

[0060] Based on the analysis of noise test data, the noise reduction effect and noise suppression ability of the model test piece under different test conditions and different parameter states are obtained.

[0061] In this embodiment, model test pieces with various parameter states can be pre-prepared in the following manner:

[0062] (1) Keeping the diameter D of the cylinder, the length L of the cylinder, the period S of the radial protrusion structure, and the thickness B of the radial protrusion structure unchanged, changing the outer diameter A of the radial protrusion structure, and preparing various models test piece;

[0063] (2) Keeping the diameter D of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com