Metal material plastic yield strength detection device

A plastic yield and strength detection technology, applied in the direction of measuring device, analyzing material, strength characteristics, etc., can solve the problems of limited contact area, loose clamping position, inaccurate results, etc., to achieve firm clamping, avoid loosening, and ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

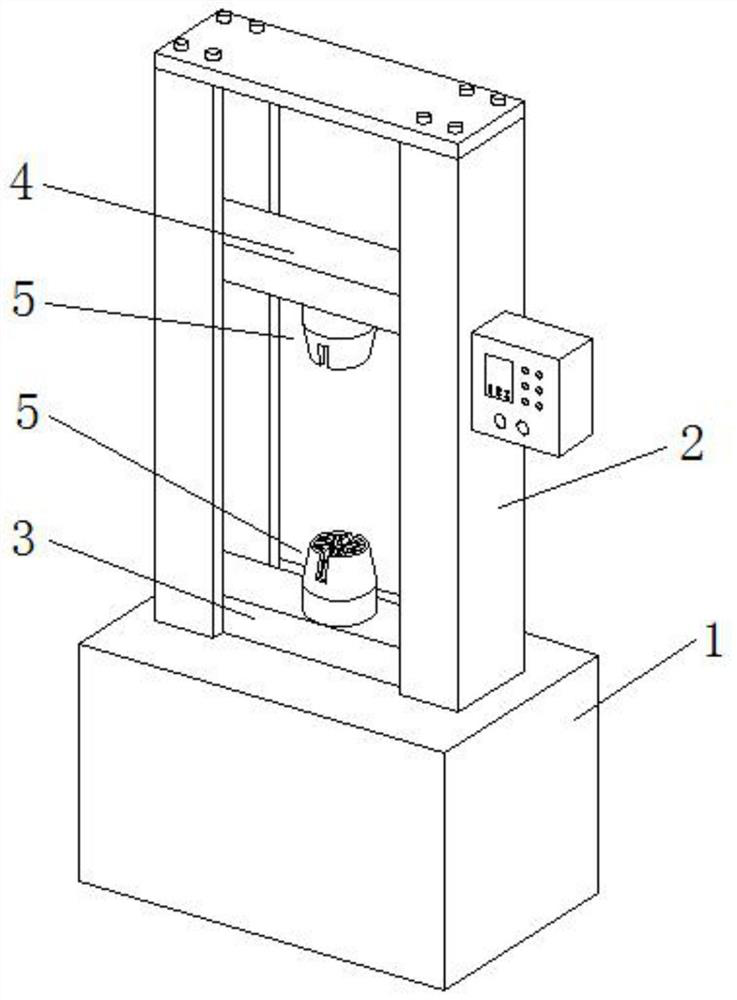

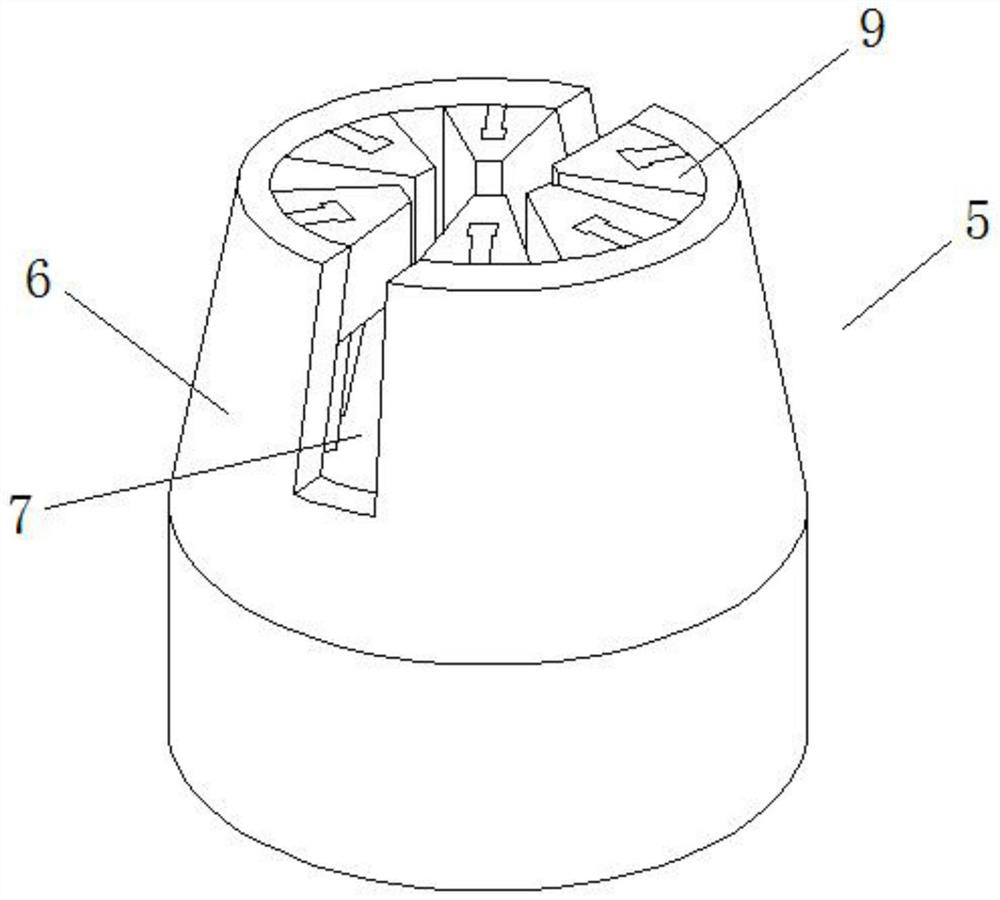

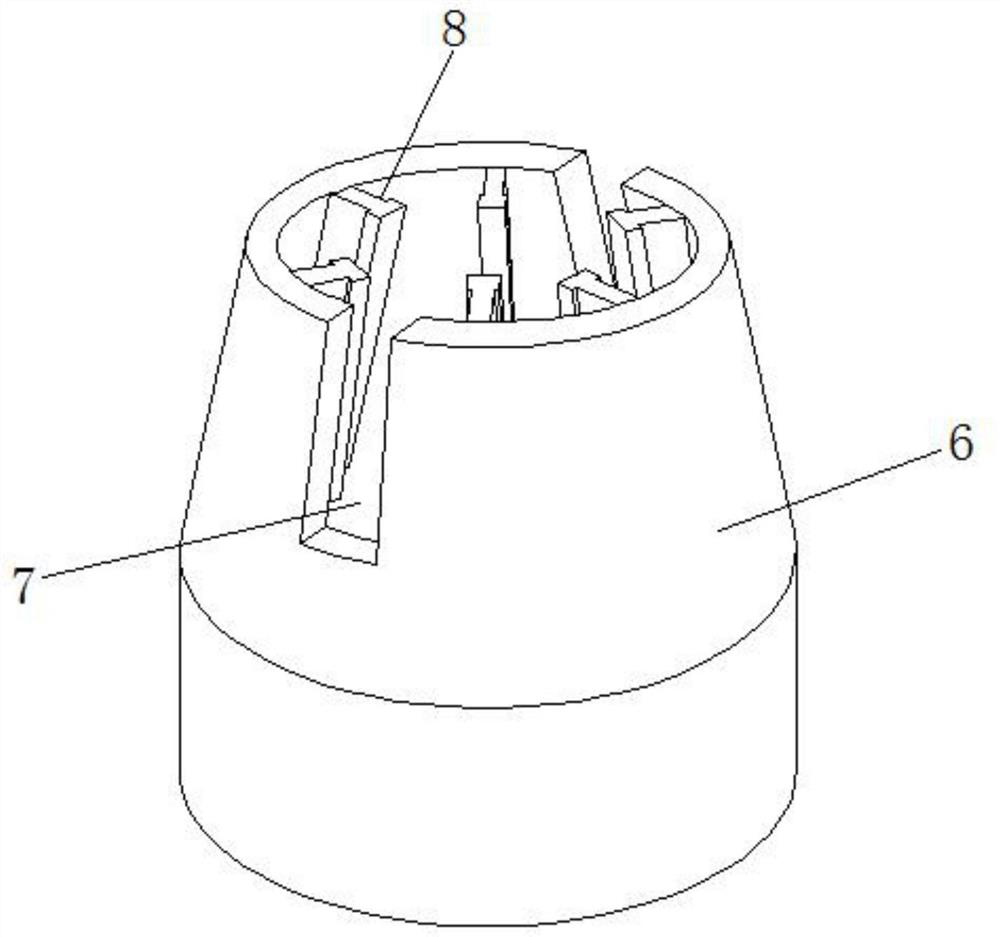

[0037] see Figure 1-4, a metal material plastic yield strength detection device, comprising a testing machine main body 1, the lower end of the bracket 2 of the testing machine main body 1 is equipped with a lower beam 3, the upper end of the bracket 2 is provided with a lifting upper beam 4, and the lower beam The middle position of the upper surface of 3 and the middle position of the lower surface of the lifting upper crossbeam 4 are fixedly installed with a chuck mechanism 5, and the chuck mechanism 5 includes an outer shell 6, and the upper side walls of the outer shell 6 are provided with The installation port 7, the upper end of the inner wall of the outer casing 6 is evenly arranged with a number of slide rails 8 on the circumference, and the sliding fan-shaped clamping blocks 9 are slidably installed on the slide rails 8, and the lower end of the inner end of the sliding fan-shaped clamping block 9 Each is provided with a fan-shaped groove 10, and a vertically arrang...

Embodiment example 2

[0044] see Figure 4 , 8 and 9, the synchronous lifting mechanism 13 includes a first support rod 16 fixed horizontally on the lower end of the inner wall of the outer casing 6 and having the same number as the sliding sector clamping block 9, and the inner ends of the first support rods 16 are all slidably installed with Vertically arranged elevating rod 17, the top of the elevating rod 17 is rotatably equipped with double-sided rollers 18 rollingly arranged inside the lower end of the sliding fan-shaped clamping block 9, and the lower end of the elevating rod 17 is provided with ring teeth 19, The lower ends of the lifting rods 17 are meshed with transmission rods 20 , and the inner parts of both ends of the transmission rods 20 are installed on the lower end of the inner wall of the outer casing 6 through the second support rods 21 .

[0045] The servo motor 26 of the synchronous lifting mechanism 13 can drive one of the transmission rods 20 to rotate through the engaged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com