Temperature control system and method for test bench

A technology of temperature control system and test bench, which is applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc., and can solve the problems of small temperature control range, low temperature control accuracy, and limited use of temperature control devices , to achieve the effect of increasing the scope of application and improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

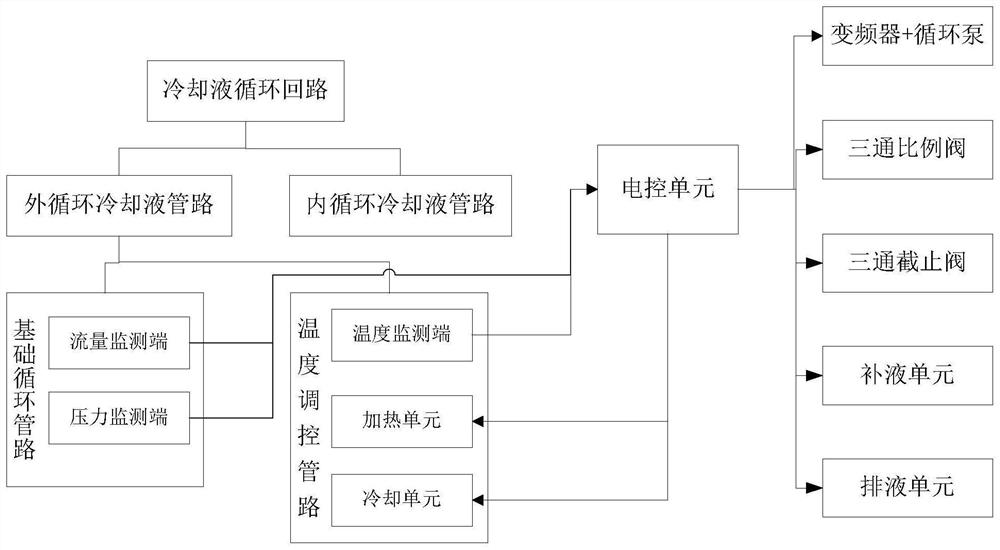

[0171] The composition and working process of this system are as follows:

[0172] according to Figure 4 It shows that the system consists of cooling water inlet / outlet pressure gauge, filter, electronic control unit, frequency converter, three-way proportional valve 3, three-way stop valve 6, cut-off ball valve (V8-V13), ordinary ball valve (V1, V2, V5-V7, V14-V17), low-level water tank, triple air source, coolant inlet / outlet pressure gauge, pressure sensor, flow meter, temperature control meter and other components.

[0173] Pneumatic triple unit is assembled with three air source processing components: air filter, pressure reducing valve and lubricator, which are used to purify, filter and depressurize the air source entering the pneumatic instrument to the rated air source pressure supplied by the instrument.

[0174] according to Figure 4 It shows that the left side of the schematic diagram is the cooling water inlet and outlet. The inlet / outlet is equipped with pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com