Customized earphone assembly equipment and assembly method

A technology for assembling equipment and earphones, which is applied in the manufacture/assembly of earphones, earpieces/earphone accessories, sensor parts, etc., which can solve the problems of consuming a lot of time and manpower, time and manpower, etc., to reduce production hours and labor occupation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Such as Figure 10 , Figure 12 The shown customized earphone holder includes a holder body 3 , and the holder body 3 includes a holder base 31 , a frame body 32 , hexagon socket screws 33 , and rubber sleeves 34 .

[0061] The two ends of the upper end surface of the fixed frame base 31 are provided with predetermined shape placement grooves 311, and the placement grooves 311 are used for placing such as Figure 11 As shown in the plastic cavity 41 of the customized earphone 4 , an installation groove 312 is provided on the upper end surface of the base 31 of the fixing frame.

[0062] The frame body 32 is assembled on the upper end of the fixing frame base 31 , the lower end of the frame body 32 is provided with a mounting block 321 matching the installation groove 312 , and a pair of screw holes 322 are provided at both ends of the upper end surface of the frame body 32 .

[0063] The inner hexagon screw 33 is assembled in the screw hole 322 , and the material of t...

Embodiment 2

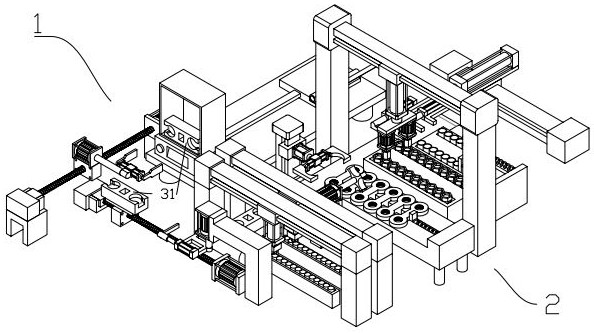

[0066] Such as Figure 1~Figure 12 As shown, a customized earphone assembly device for assembling the above-mentioned customized earphone holder and assembled customized earphones includes a transfer unit 1 and an assembly unit 2 .

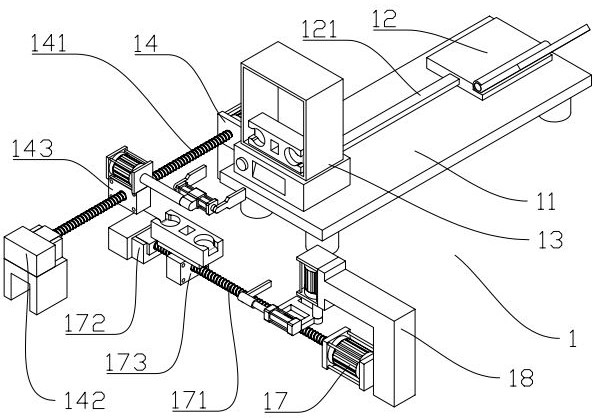

[0067] The transfer unit 1 includes a table body 11, a computer 12 is arranged on the upper surface of the table body 11, a communication cable 121 is connected to one end of the computer 12, and a 3D printer 13 is connected to one end of the communication cable 121, and the 3D printer 13 is used to receive data from the computer 12 for printing. The fixed frame base 31 of a predetermined shape, the printed placement slot 311 of the fixed frame base 31 faces the feeding end of the 3D printer 13 .

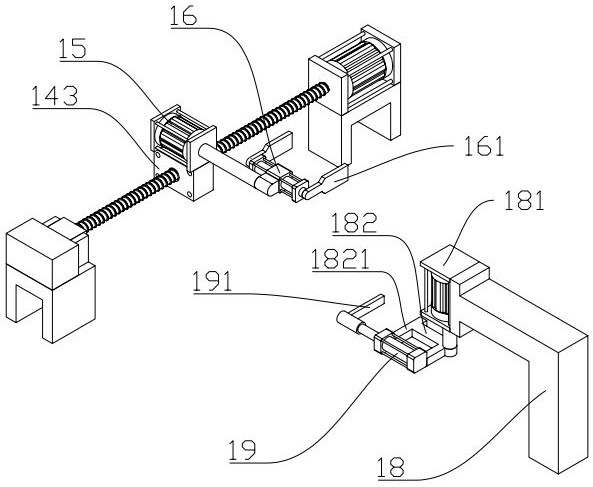

[0068] The feeding end of the 3D printer 13 is provided with a transfer assembly, the transfer assembly is used to transfer the printed fixed frame base 31, the transfer assembly includes a first screw motor 14 arranged at a predetermined distance from ...

Embodiment 3

[0078] A custom earphone assembly method using the above-mentioned custom earphone assembly equipment is operated according to the following steps:

[0079] S01: On the computer 12, select the fixed frame base 31 corresponding to the customized earphone customized with the ear mold of the predetermined customer, and send it to the 3D printer 13 through the communication cable 121 for printing.

[0080] S02: Start the first screw motor 14, move the first slider 143 through the first screw 141, the first slider 143 drives the first two-way cylinder 16 close to the fixed frame base 31, start the first two-way cylinder 16, use the first The splint 161 clamps the base 31 of the fixed frame, starts the first screw motor 14 , and moves the first two-way cylinder 16 away from the 3D printer 13 .

[0081] S03: when step S02 ends, perform the operation of step S1 on the fixing frame base 31 corresponding to the next customized earphone.

[0082] S04: As a follow-up step to step S02, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com