Filler and preparation method of filler

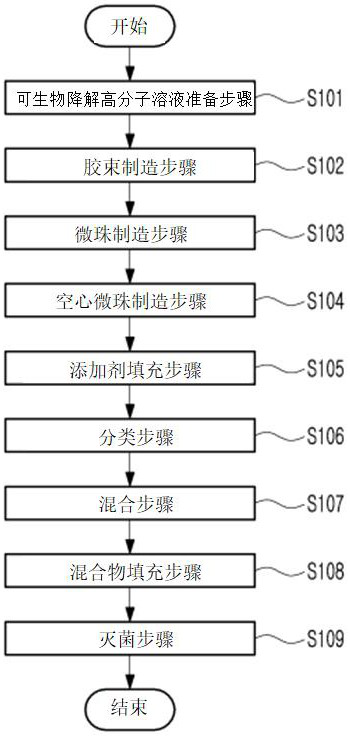

A technology of fillers and preparation steps, which is applied in the field of fillers and filler preparations, can solve the problems of poor tissue repair effect, difficulty in forming delicate and natural shapes, pain, etc., and achieve the effect of simplifying the classification process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

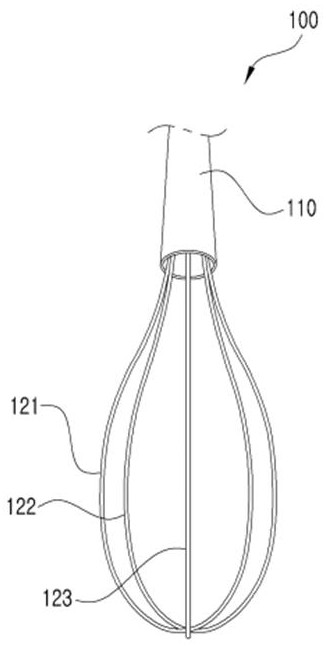

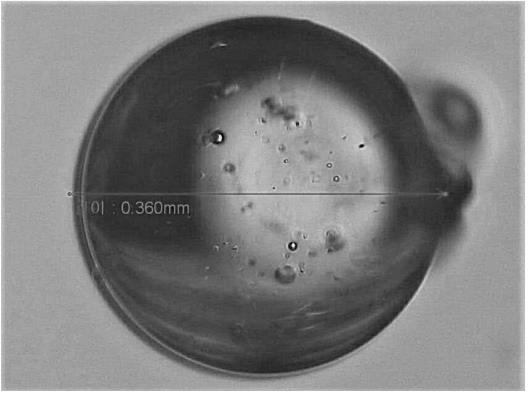

[0034] Preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings, but for the sake of brevity, technical parts that are already well known will be omitted or condensed.

[0035] It should be noted that references in this specification to "one" or "an" embodiment of the invention are not necessarily the same embodiment, but refer to at least one.

[0036] In the following embodiments, the use of terms such as first and second is not intended to limit their meanings, but is used to distinguish one technical feature from other technical features.

[0037] In the following examples, unless the context clearly dictates otherwise, singular expressions include plural expressions.

[0038] In the following examples, terms such as 'including' or 'having' refer to the presence of the features or techniques described in the specification

[0039] feature, not an additional possibility that precludes more than one other fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com