Filler and preparation method thereof

A filler and a technology for preparation steps, applied in the field of filler and filler preparation, can solve the problems of poor tissue repair effect, difficulty in forming a delicate and natural shape, pain, etc., and achieve the effects of simplifying the classification process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] .

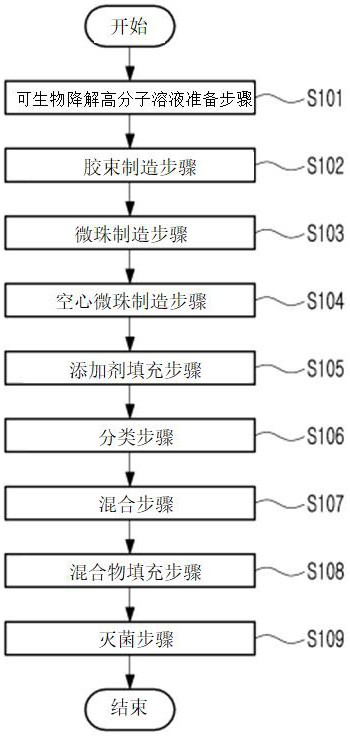

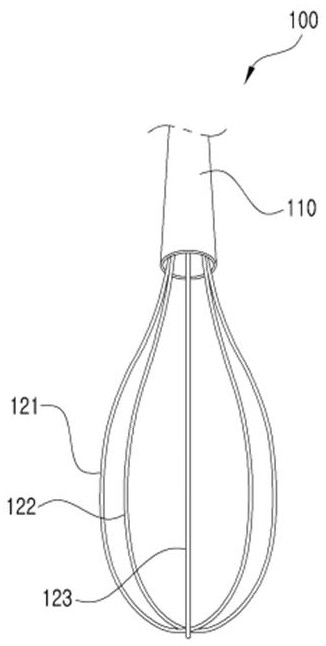

[0086] Mix sodium hyaluronate with 1N sodium hydroxide solution to make the concentration of sodium hyaluronate reach 10w / v%, and stir for 3-4 hours to prepare a biodegradable polymer solution. Mix the prepared biodegradable polymer solution with mineral oil, rotate with an impeller at 1000-2000 rpm for 30 minutes to 15 hours, and stir the mixed solution of biodegradable polymer solution and mineral oil at high speed. When mixing the biodegradable polymer solution with mineral oil, the content was set to the values described in Table 1 below. The impeller structure and figure 2 Similarly, an impeller with three steel wires crossing each other at an angle and fixed to the rotating shaft is used.

[0087] After that, a cross-linking agent (butanediol diglycidyl ether) was added to the stirring material, and after stirring at 1000 rpm, the polymer micelles were cross-linked at room temperature for 24 hours. At this time, the content of the crosslinking age...

Embodiment 2

[0090] .

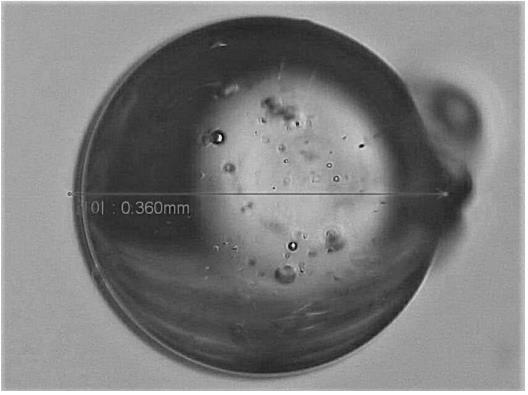

[0091] In addition to setting the content of the cross-linking agent as described in the following table 2, and putting the hydrogel microbeads classified according to the diameter of 50-500 μm into a vacuum oven, and drying them under vacuum at 20mmHg for 1 hour at 60°C , the setting of other matters when preparing hydrogel microbeads is the same as that of Example 1.

[0092] 【Table 2】

[0093] .

Embodiment 3~4

[0094] .

[0095] Except that the number of steel wires of the impeller was set according to the values listed in Table 3, the setting of other matters during the preparation of hydrogel microbeads was the same as in Example 1.

[0096] 【table 3】

[0097] .

[0098] Productivity evaluation of hydrogel microbeads.

[0099] To confirm the productivity of different biodegradable polymer solution to mineral oil volume ratios, the following experiments were performed. In the production process of each Example and Comparative Example, after recovering the hydrogel beads filled with additives, the hydrogel beads were sorted by size using a sieve. When the proportion of beads with a diameter of 50 to 500㎛ in all the produced hydrogel beads exceeds 80%, it is evaluated as excellent in productivity, and when it is less than 80%, it is evaluated as poor in productivity. The results are shown in Table 4 below.

[0100] 【Table 4】

[0101] .

[0102] As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com