Welding-free splicing type heavy frame beam

A beam erecting and heavy-duty technology, which is applied in the direction of welding equipment, laser welding equipment, gas flame welding equipment, etc., can solve the problems of inconvenient disassembly and assembly of beam erection, high labor cost, and inconvenient transportation, so as to improve the fixing firmness, The effect of low replacement cost and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

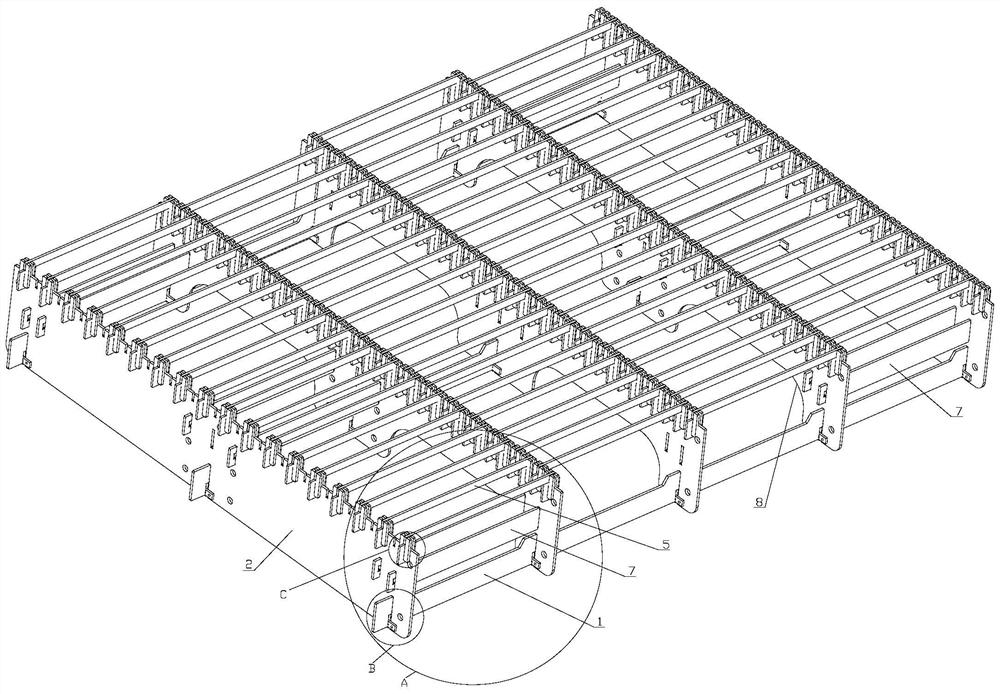

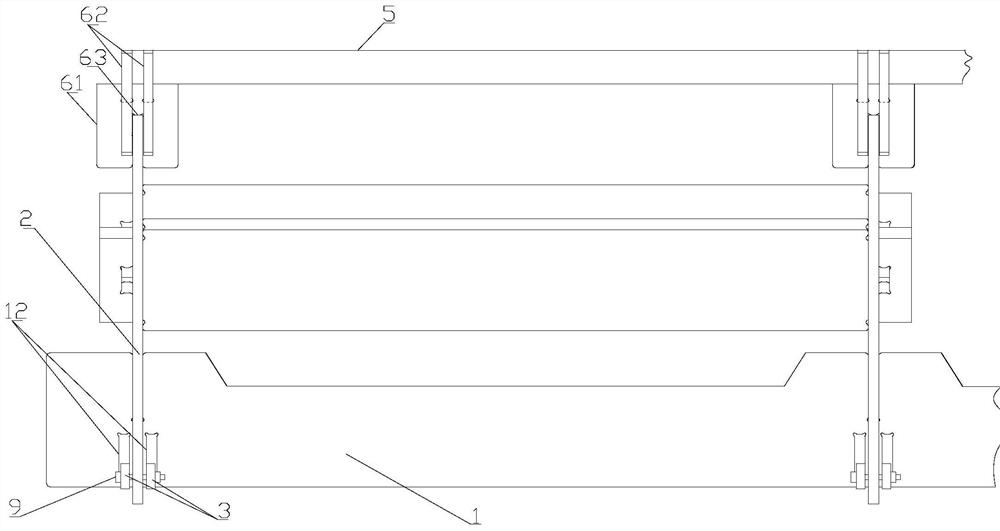

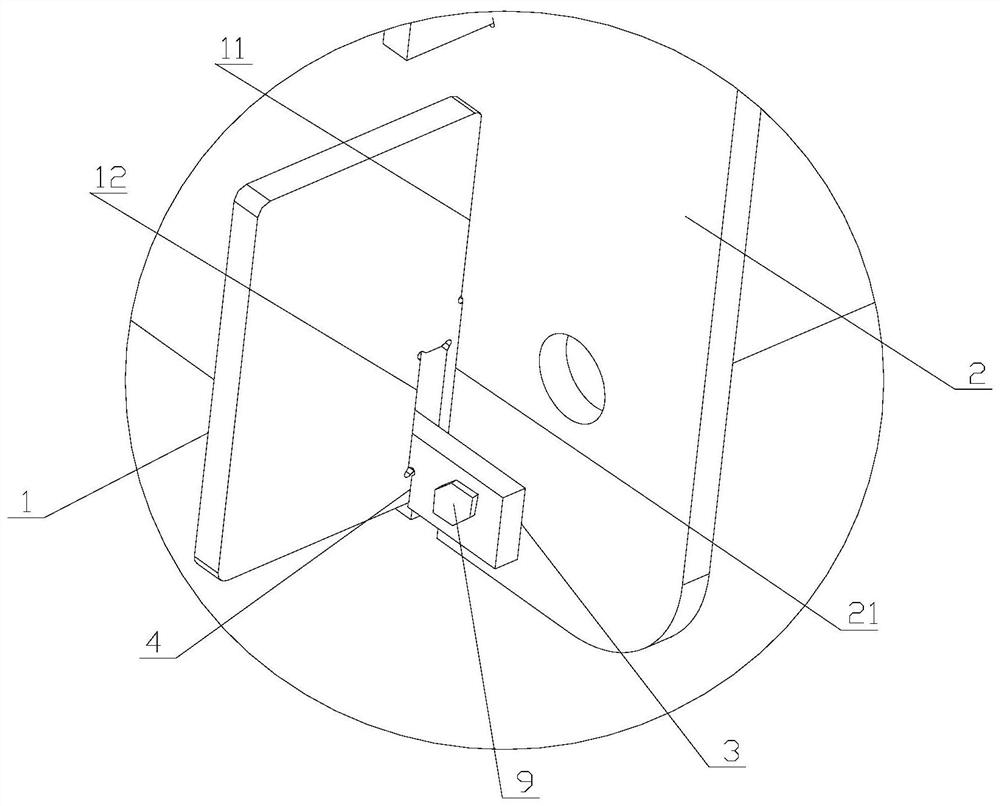

[0026] refer to figure 1 , figure 2 , image 3 and Figure 4 , a welding-free splicing heavy-duty girder according to the present invention, which includes several positioning bodies 1 and several load-bearing bodies 2, the positioning bodies 1 and load-bearing bodies 2 are intersected and connected together with mortise and tenon joints, and the lower ends of the load-bearing bodies 2 are arranged There is a socket I21 matching with the positioning body 1, the upper end of the positioning body 1 is provided with a socket II11 matching with the load-bearing body 2, and the positioning body 1 is provided with sockets 12 on both sides of the load-bearing body 2 , the locking bodies 3 are provided in the socket holes 12, the load-bearing body 2 is fixedly connected with the locking bodies 3 on both sides through the bolts and nuts 9, and the lower end of the locking body 3 is provided with the positioning body 1. The matching socket III4 also includes several force-bearing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com