Full-degree-of-freedom air pressure floating type deburring device

A deburring and degree of freedom technology, applied in the direction of grinding/polishing safety devices, grinding machine parts, metal processing equipment, etc., can solve the problems of spindle shaking, internal jamming of the device, and affecting the device, so as to improve work efficiency , increase the stability, increase the effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

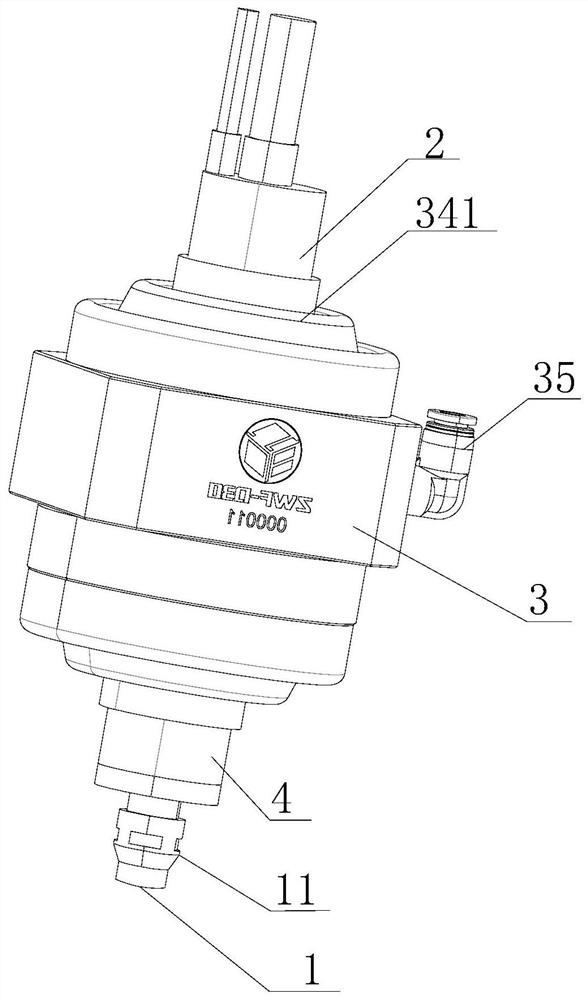

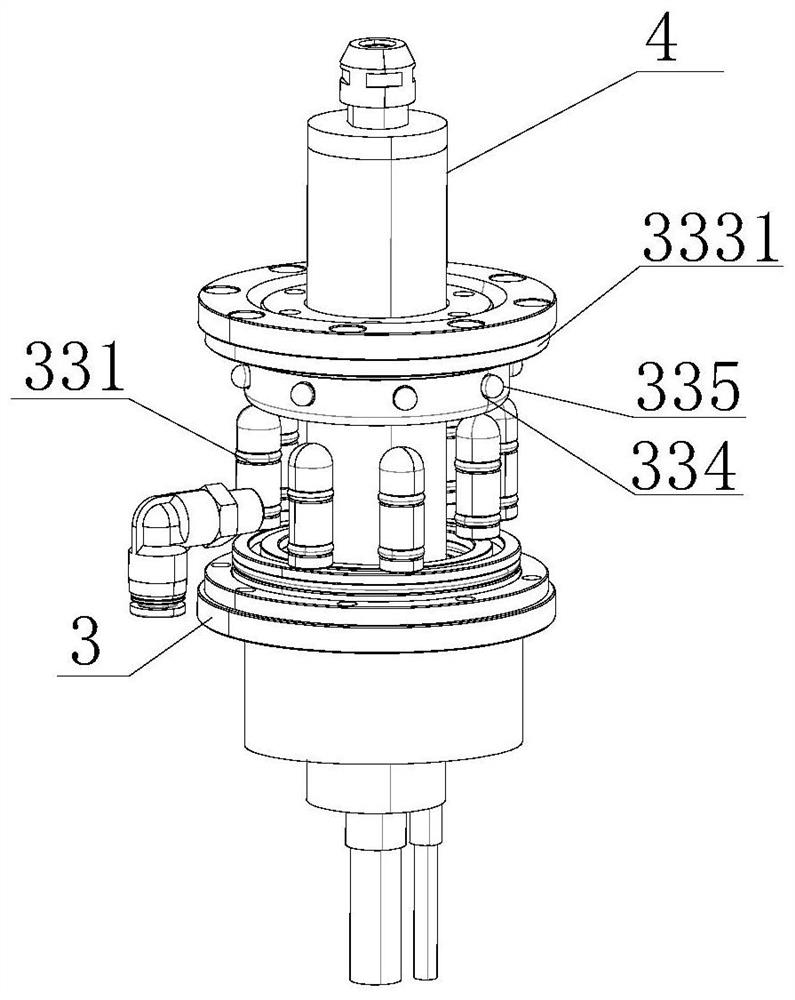

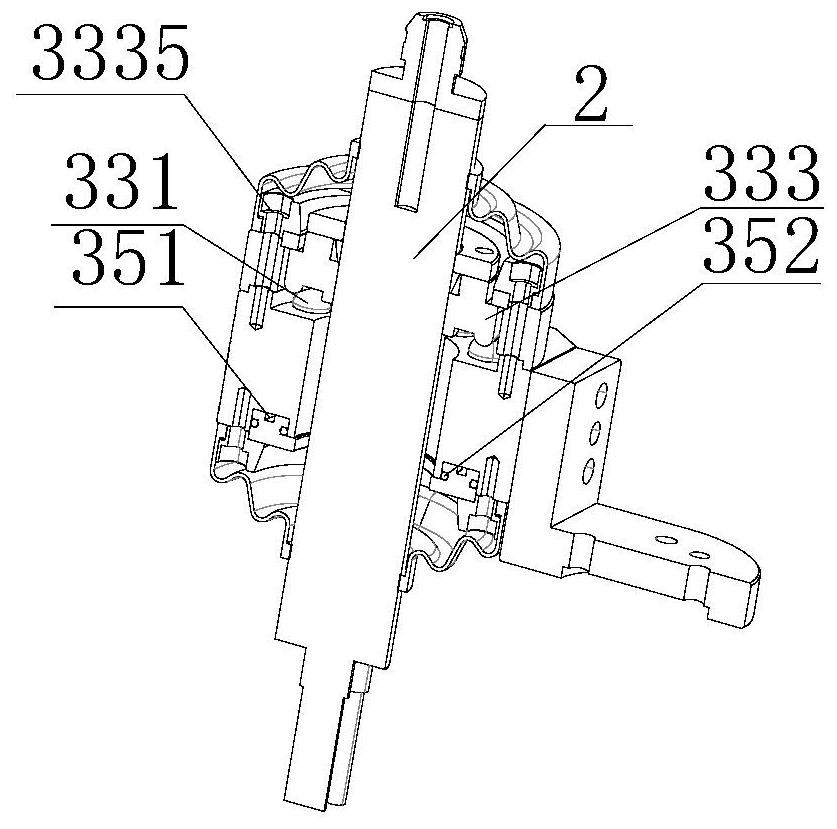

[0041] Such as Figure 1-7 As shown, the present invention provides a full-degree-of-freedom pneumatic floating deburring device, which includes a deburring device main body 1, a main shaft 2, a middle shaft layer 3, and a bottom shaft 4. The top of the deburring device main body 1 is movably connected with a connecting shaft 11. The bottom shaft 4 is installed on the top of the connecting shaft 11, the middle shaft layer 3 is fixedly installed on the top of the bottom shaft 4, the main shaft 2 is fixedly installed on the inner side of the middle shaft layer 3, and the sealing shaft 31 is fixedly installed on the top of the middle shaft layer 3 , the top of the sealing shaft 31 is fixedly installed with a connecting column 32, the inside of the middle shaft layer 3 is fixedly installed with a stabilizing mechanism 33, the top and bottom of the middle shaft layer 3 are fixedly installed with a dust-proof shaft 34, and the stabilizing mechanism 33 includes a moving piston 331 , ...

Embodiment 2

[0044] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top of the limit shaft 3331 is provided with a limit hole 3330, and the inner side of the pressure ring 3332 is fixedly installed with a collar block, and the inner side of the collar block is fixed. A hoop 3333 is installed, and the inner side of the pressure ring 3332 is fixedly installed with a hoop 3333 , and the inner side of the hoop 3333 is fixedly installed on the outer side of the main shaft 2 .

[0045] In this embodiment, the limit block is plugged into the limit hole 3330, so that the limit shaft 3331 reaches the limit and fixation of the main shaft 2, and then the collar block and the hoop 3333 cooperate with each other to increase the support for the main shaft. 2 is fixed to prevent the main shaft 2 from shaking left and right during operation, resulting in a decrease in accuracy, so that the main shaft 2 can stably drive the ma...

Embodiment 3

[0047] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a dustproof cover 341 is fixedly installed inside the dustproof shaft 34, and a fixed shaft 342 is fixedly installed at the bottom of the dustproof cover 341 to prevent The interior of the dust cover 341 is fixedly installed with an adsorption column 3411 , and fixed blocks 3412 are fixedly installed at both ends of the adsorption column 3411 , and the other side of the fixed block 3412 is fixedly installed on the inner wall of the dust cover 341 . The outer side of the fixed shaft 342 is provided with a fixed hole 3421 , and the inside of the fixed shaft 342 is fixedly sleeved with a retaining ring 3422 .

[0048] In this embodiment, debris and dust are filtered and blocked by the dust cover 341 at both ends of the central axis layer 3, and then the adhesion of the surface of the adsorption column 3411 is combined to adhere to the finer dust ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com