Energy-saving and environment-friendly high polymer material cutting device

A polymer material, energy saving and environmental protection technology, applied in the direction of metal processing, etc., can solve the problems of difficult to clean, dangerous, and inconvenient to clean the work floor, and achieve the effect of avoiding the splash of waste and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

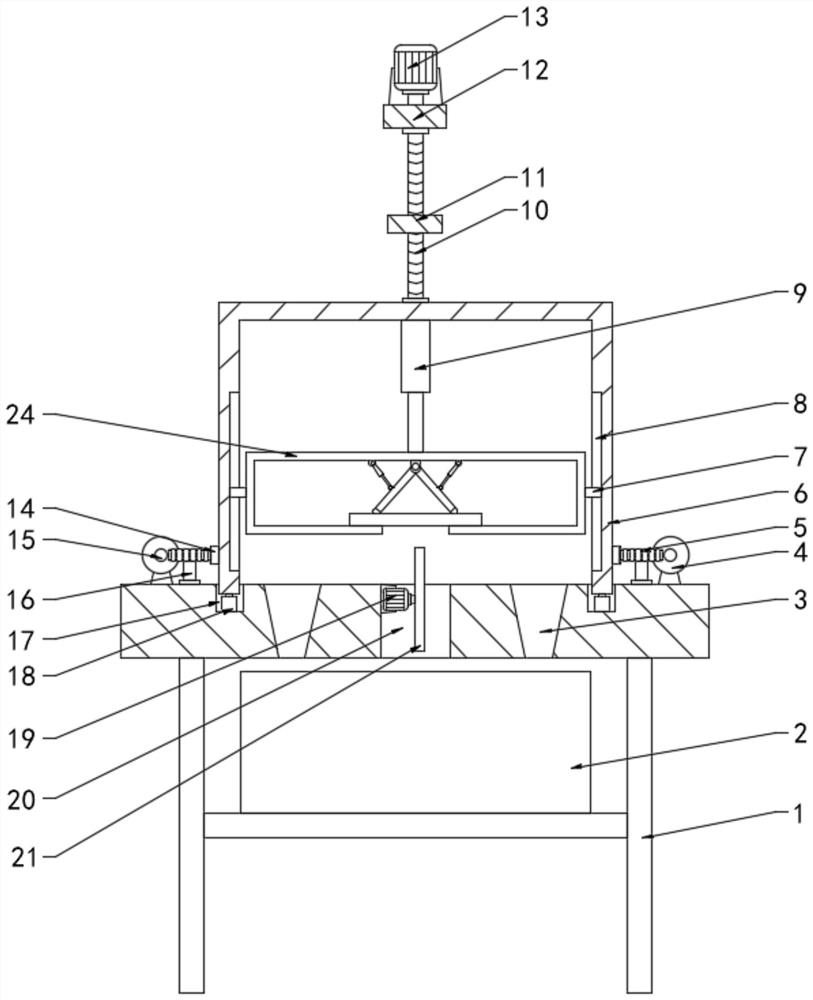

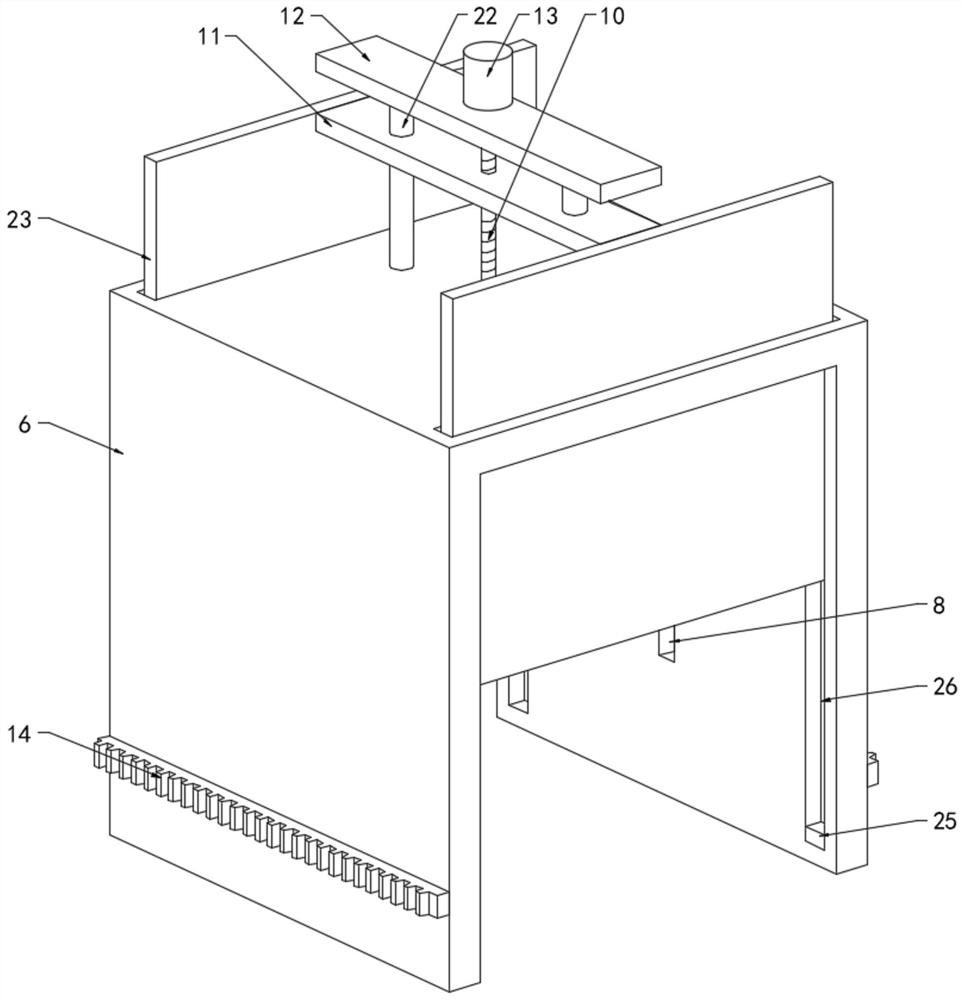

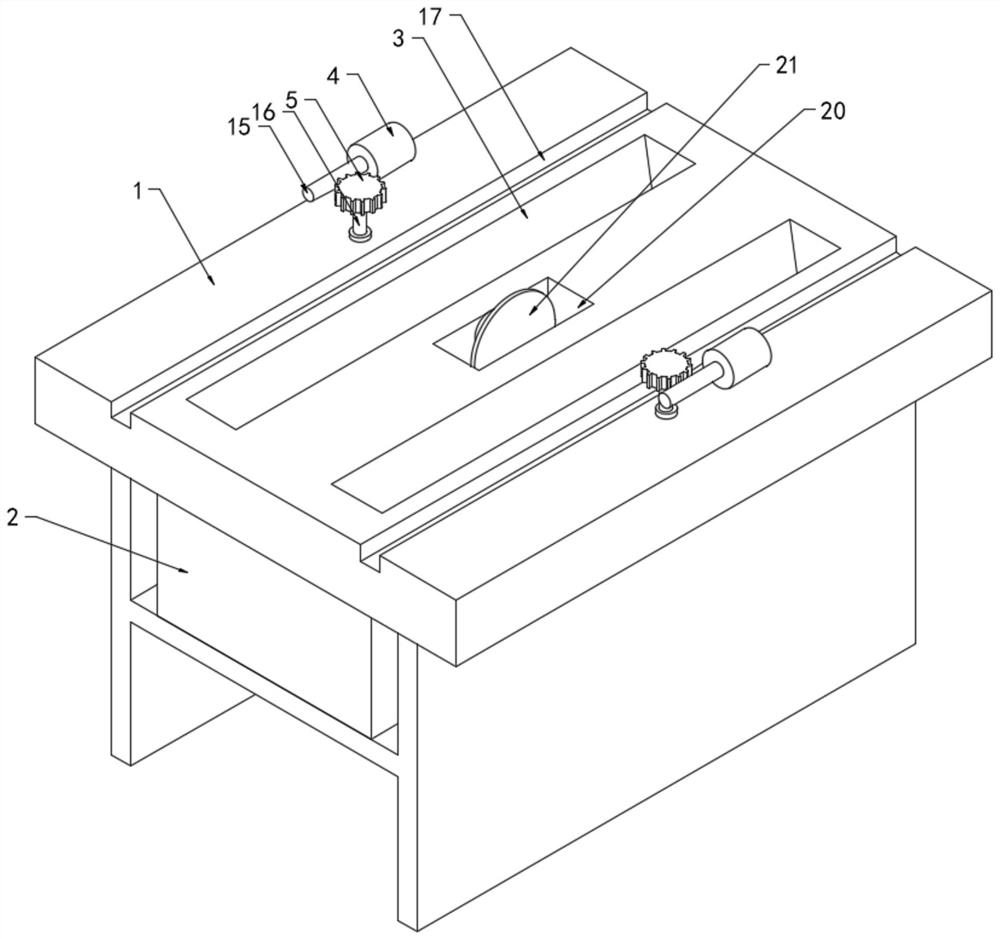

[0042] see Figure 1-10 , the present invention provides a technical solution: an energy-saving and environment-friendly cutting device for polymer materials, comprising a frame 1 and a workpiece 31, the top of the frame 1 is provided with a second through slot 20, and one side of the second through slot 20 is fixedly installed with The 3rd driving motor 19, the output shaft transmission of the 3rd driving motor 19 is connected with cutter 21, and frame 1 top slides and is connected with the protective cover 6 that is positioned at cutter 21 outsides, and frame 1 both sides is provided with drive protective cover 6 on A mobile device that moves horizontally on the frame 1. A third through groove 26 is provided on both sides of the frame 1. A baffle plate 23 is slidably connected in the third through groove 26. An elastic pad 25 is bonded to the bottom of the third through groove 26. The top of the frame 1 is provided with an opening and closing device that drives the baffles 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com