Building board pouring equipment

A technology for building boards and equipment, applied in the field of building boards, can solve the problems of prolonged board forming time, low pouring efficiency, increased bubble generation, etc., so as to improve pouring and forming efficiency, improve cleaning effect and efficiency, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

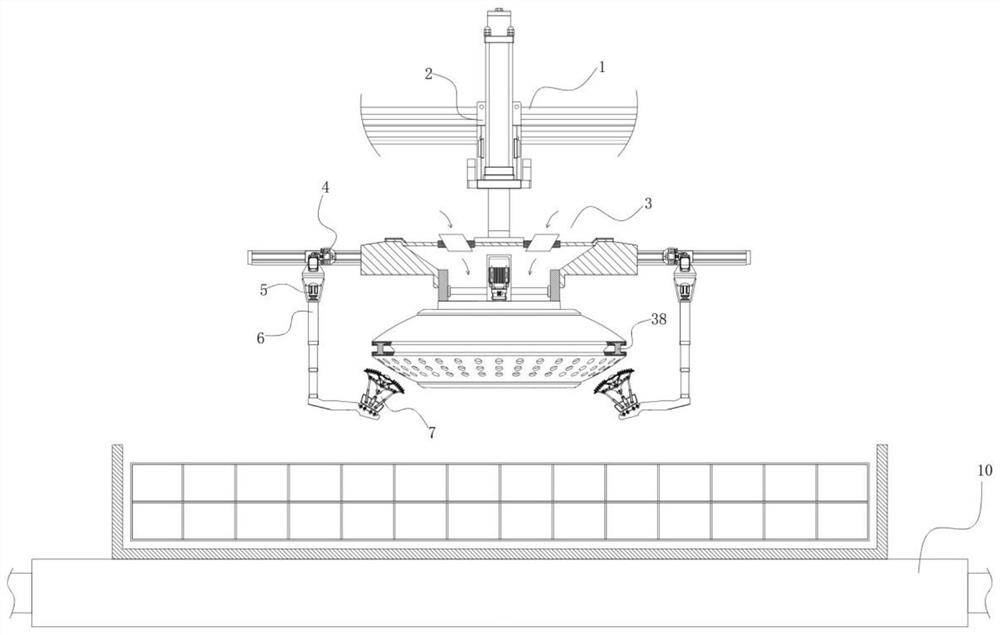

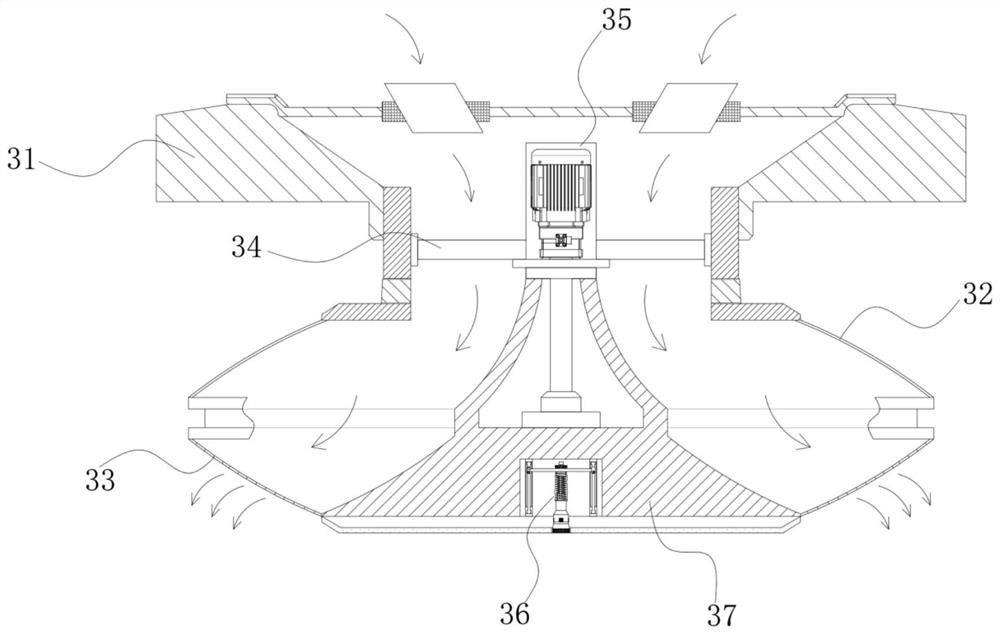

[0050] refer to figure 1 , the present invention provides a technical solution: a building plate pouring equipment, which includes:

[0051] Conveyor belt 10 for conveying sheet metal frames;

[0052] The lifting assembly 2 is slidably connected to the transverse guide rail 1;

[0053] The pouring device 3 is installed on the output end of the lifting assembly 2, and a side lateral moving device 4 is installed on the left and right sides;

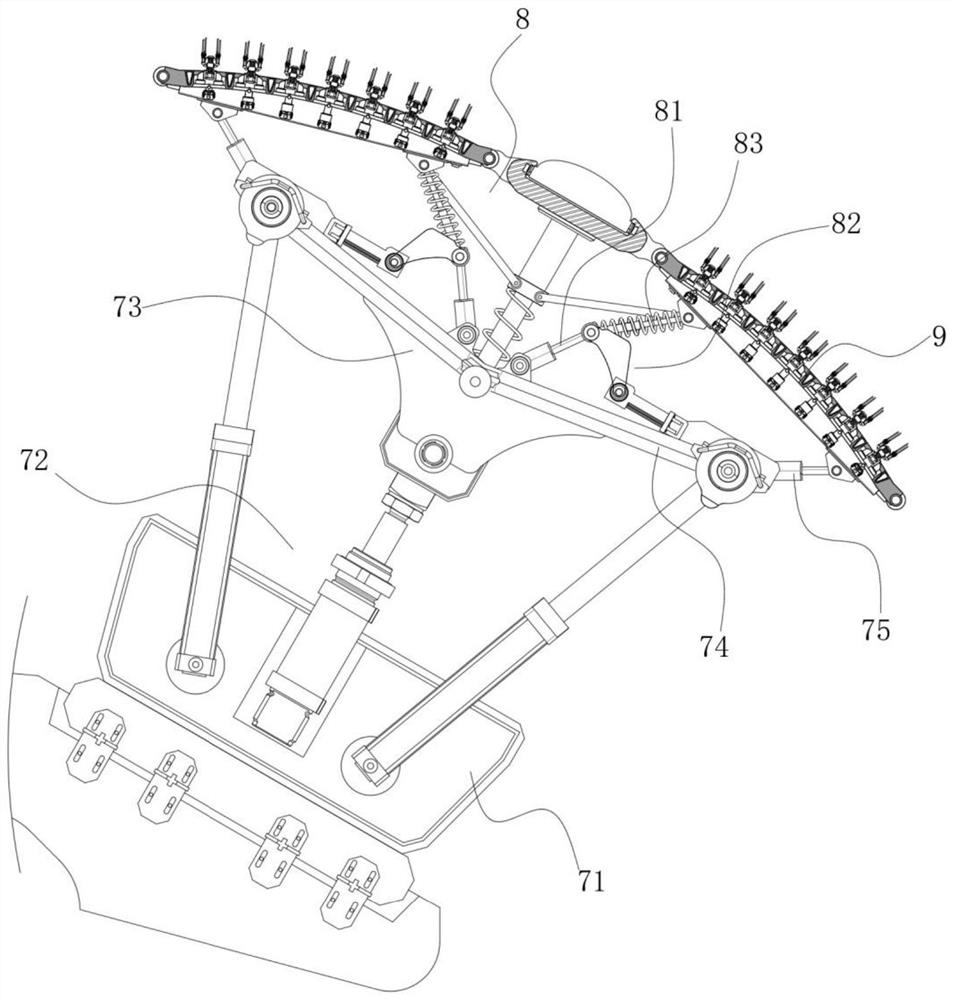

[0054] The lifting arm 6 is provided with two groups, which are respectively installed on the side lateral moving device 4, and are driven by the rotating motor 5 to rotate;

[0055] The cleaning device 7 is provided with two groups, respectively installed on the output end of the lifting arm 6;

[0056] Wherein, the lifting arm adjusts the height of the cleaning device, and the rotating motor adjusts the external rotation of the lifting arm to stop operation, and the internal rotation to start operation.

[0057] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com