Umbrella cloth printing method capable of eliminating influence of sewing on pattern integrity and umbrella

A printing method and integrity technology, applied in the field of umbrellas, can solve problems such as pattern misalignment, and achieve the effect of eliminating white edges, complete umbrella surface patterns, and high splicing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

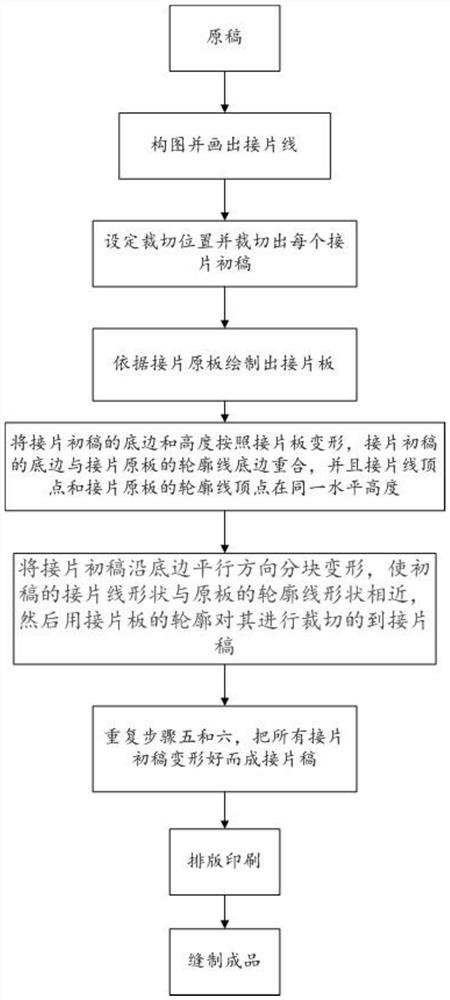

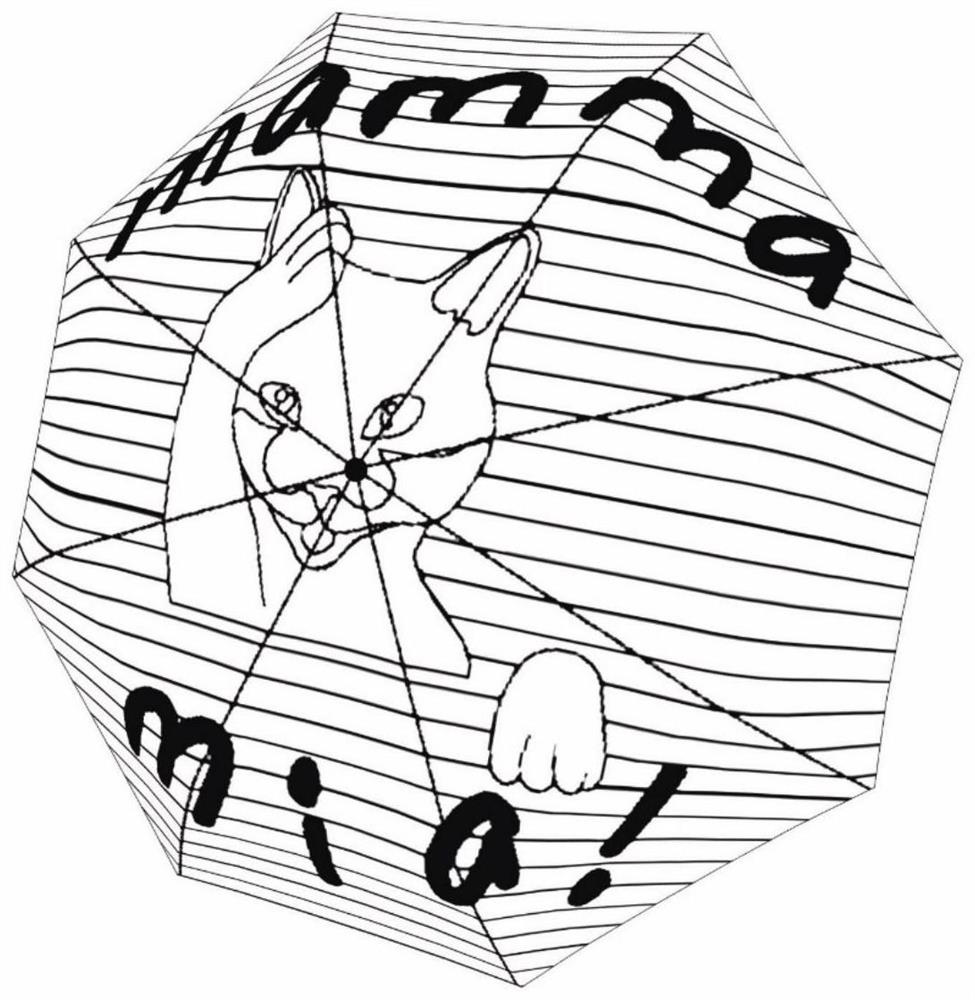

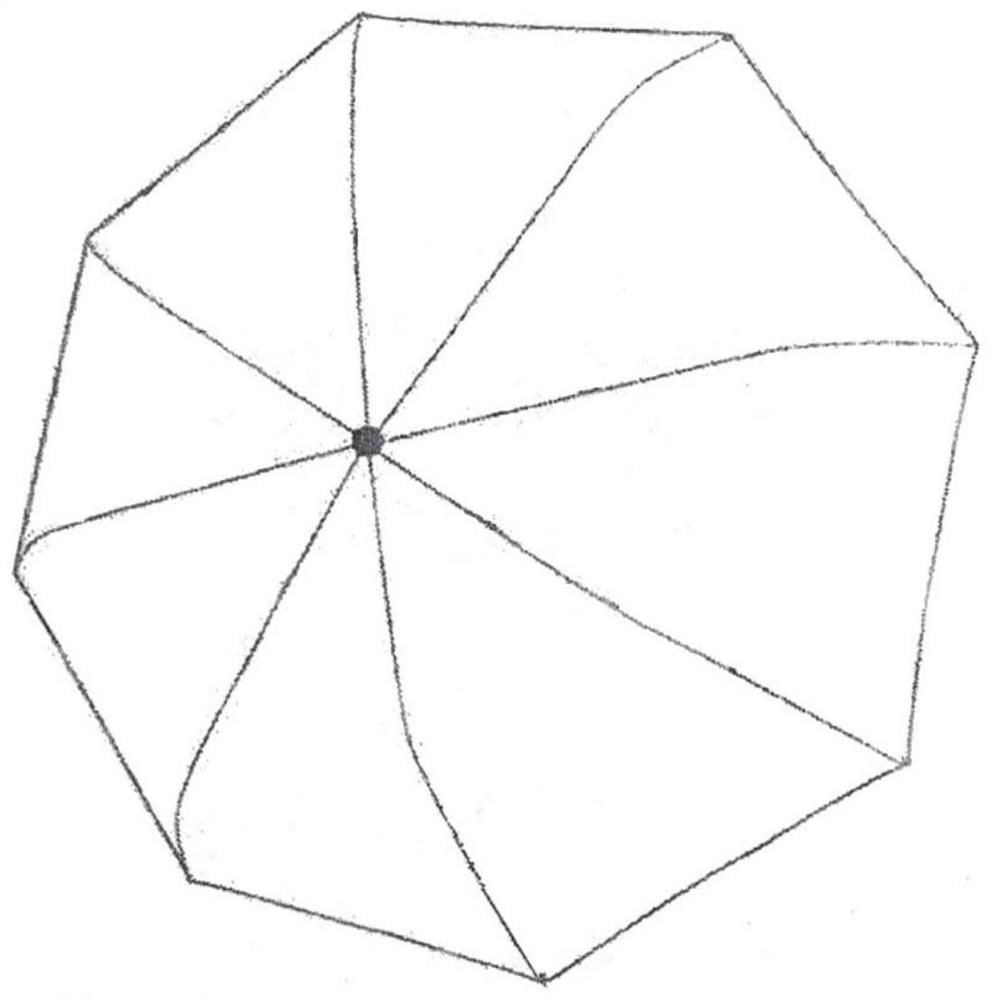

[0072] Such as figure 2 As shown, a 8K regular octagonal umbrella surface has eight equally divided triangular pieces, and its printing method is as follows: Figure 2-Figure 14 As shown, the specific steps are as follows:

[0073] Step 1: The umbrella manufacturer provides the original design of the umbrella pattern, which is a cat pattern;

[0074] Step 2: If Figure 5 As shown, design the original according to the Figure 4 The regular octagon composition of the orthographic projection of the umbrella surface, and draw the splicing lines according to the shape and number of the umbrella surface splices. Specifically, the splicing lines divide the regular octagonal composition into eight identical triangles;

[0075] Step 3: Cut out a square draft of the splice; Figure 7 As shown, the first draft of the tab includes a pattern bounded by the bottom edge of the tab and the tab line (that is, the pattern inside the triangle), and also includes a part of the pattern outsid...

Embodiment 2

[0083] Such as Figure 15 As shown, an 8K umbrella cover has four long and narrow triangular joints and four short and wide triangular joints. The printing method is as follows: Figure 15-Figure 27 As shown, the specific steps are as follows:

[0084] Step 1: The umbrella manufacturer provides the original design of the umbrella pattern, which is a cat pattern;

[0085] Step 2: If Figure 18 As shown, design the original according to the Figure 17 The octagonal composition of the orthographic projection of the umbrella surface, and draw the splicing lines according to the shape and number of the splicing pieces of the umbrella surface. Specifically, the splicing lines divide the octagonal composition into four pieces of long and narrow triangle pieces and four pieces of short pieces. Wide triangular tabs;

[0086] Step 3: Cut out a square draft of the splice; Figure 20-21 As shown, the first draft of the tab includes a pattern bounded by the bottom edge of the tab and ...

Embodiment 3

[0094] Such as Figure 28 As shown, a 24K regular 24-sided umbrella surface has 24 equally divided triangular pieces, and its printing method is as follows: Figure 28-37 As shown, the specific steps are as follows:

[0095] Step 1: The umbrella manufacturer provides the original design of the umbrella pattern, which is a cat pattern;

[0096] Step 2: If Figure 28 As shown, design the original according to the Figure 30 The regular twenty-four-sided composition of the orthographic projection of the umbrella surface, and draw the splicing lines according to the shape and number of the umbrella surface splices. Specifically, the splicing lines divide the octagonal composition into twenty-four equally divided triangles. piece;

[0097] Step 3: Cut out a square draft of the splice; Figure 33 As shown, the first draft of the tab includes a pattern bounded by the bottom edge of the tab and the tab line (that is, the pattern inside the triangle), and also includes a part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com