Self-adjusting material loading device

A material loading and self-adjusting technology, which is applied in the directions of packaging, conveyor objects, transportation and packaging, etc., can solve the problems that affect the time of cement plant commissioning, increase the time of equipment debugging, and long loading time, so as to achieve convenient operation and wide application range The effect of wide and easy unloading operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

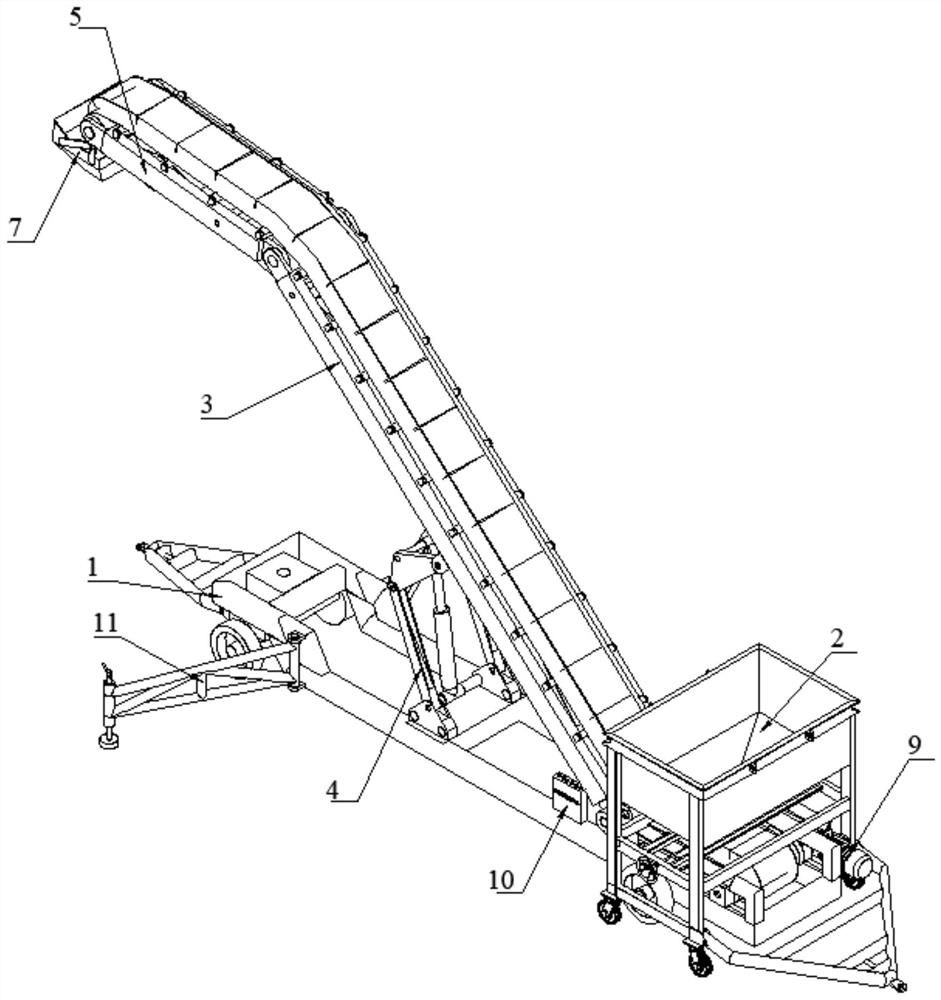

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0034] refer to Figure 1-3 , a self-adjusting material loading device of the present invention includes a traveling frame 1 and a lifting mechanism on it, and also includes a loading bucket 2 and a balance bracket 11 arranged on the traveling frame 1 . The walking vehicle frame 1 is a four-wheel structure, and balance supports 11 are provided on both sides to prevent rollover. The balance supports 11 are made of shrinkable steel trusses and hydraulic support legs at the ends. The front end of the traveling vehicle frame 1 is provided with a steering mechanism, and the position of the self-adjusting material loading device as a whole can be moved through traction equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com