Efficient water-sediment separation device

A water-sand separation and separation device technology, which is applied in the direction of heating water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the effect of separation efficiency of the device, increase the wear of internal components, reduce the device Service life and other issues to achieve the effect of improving efficiency, reducing difficulty and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

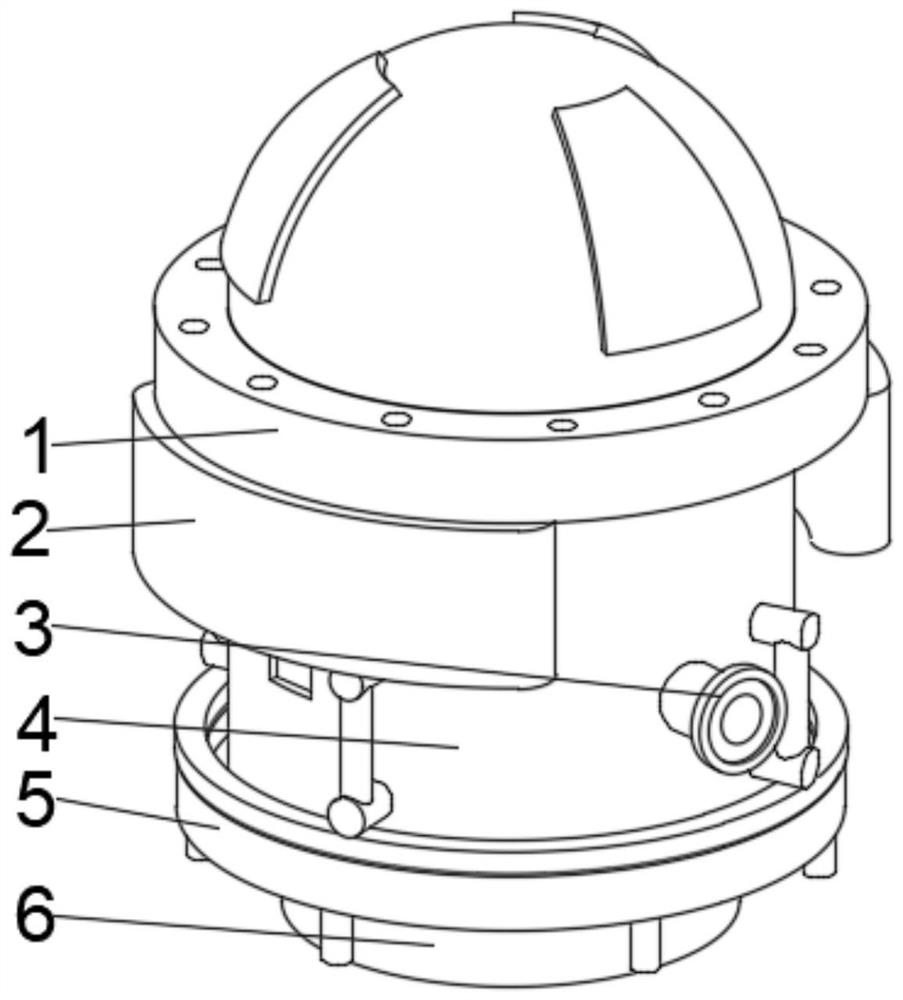

[0040] see Figure 1-6 , the present invention provides a technical solution: a high-efficiency water-sand separation device, including a fixed base 6, the top of the fixed base 6 is fixedly connected with a separation device 4, and the top of the fixed base 6 is located on both sides of the separation device 4. The sand ring 5, the water inlet pipe 3 is connected to the middle of the bottom of the outer wall on the right side of the separation device 4, and the flow pipe 1 is fixedly connected to the top of the outer wall on both sides of the separation device 4, and the top of the separation device 4 is connected to both sides of the bottom of the flow pipe 1. There are 2 water storage tanks.

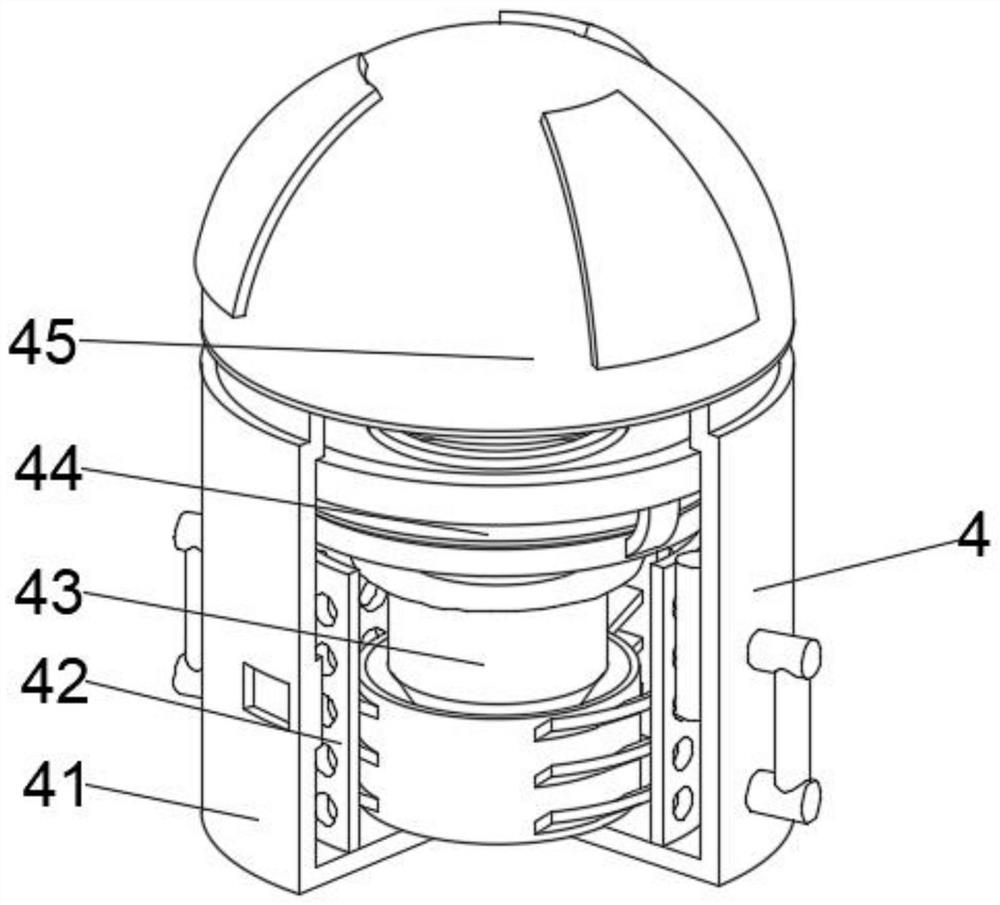

[0041] Wherein, the separation device 4 comprises a separation cylinder 41, a collection mechanism 43 is arranged at the middle position of the inner chamber bottom of the separation cylinder 41, and a transition turntable 44 is fixedly connected to the top of the collection mechanism...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an efficient water-sand separation device, step 1: fix the device through the fixed base 6, and connect the separation device 4 through the water inlet pipe 3 A sufficient amount of water is injected into the interior, and the flow pipe 1 is connected with the water storage tank 2;

[0048] Step 2: Connect the screening mechanism 45 to the collection mechanism 43 via the transitional turntable 44, and use the circulation pipe provided outside the separation cylinder 41 to transport the water body to the inside of the screening mechanism 45, so that the limit screen 42 is connected to the separation cylinder 41;

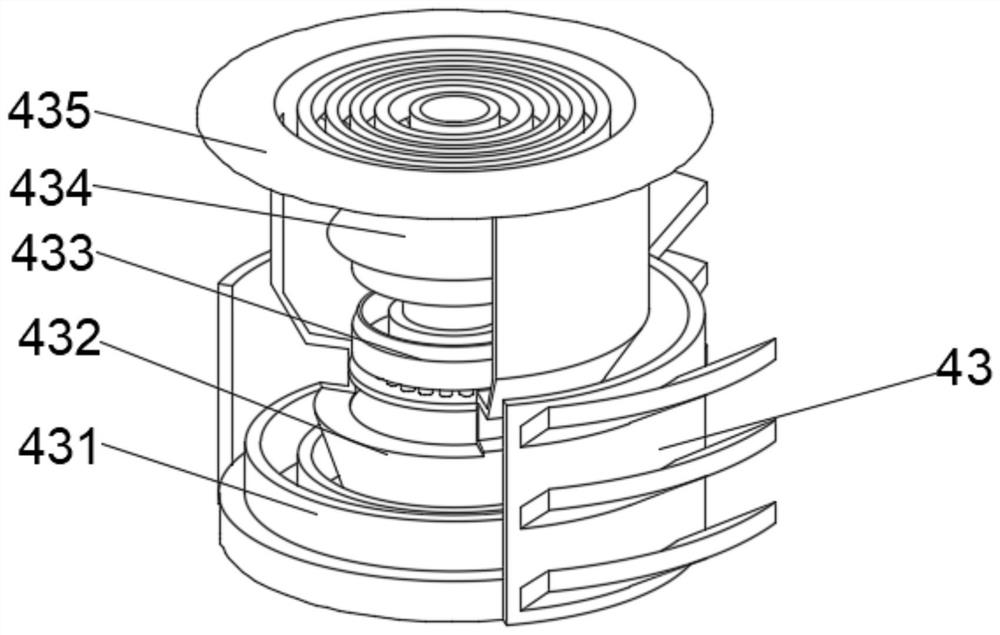

[0049] Step 3: When the water body falls, first contact the support plate 435, use the groove of the support plate 435 to drop to the inside of the solid block 432, connect the overflow body 434 with the fine filter 433, and clean the sand or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com