Method for preparing multi-scale porous structure on surface of polyether-ether-ketone

A polyetheretherketone, porous structure technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problem of single preparation, and achieve the effect of improving osseointegration performance, mechanical performance and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

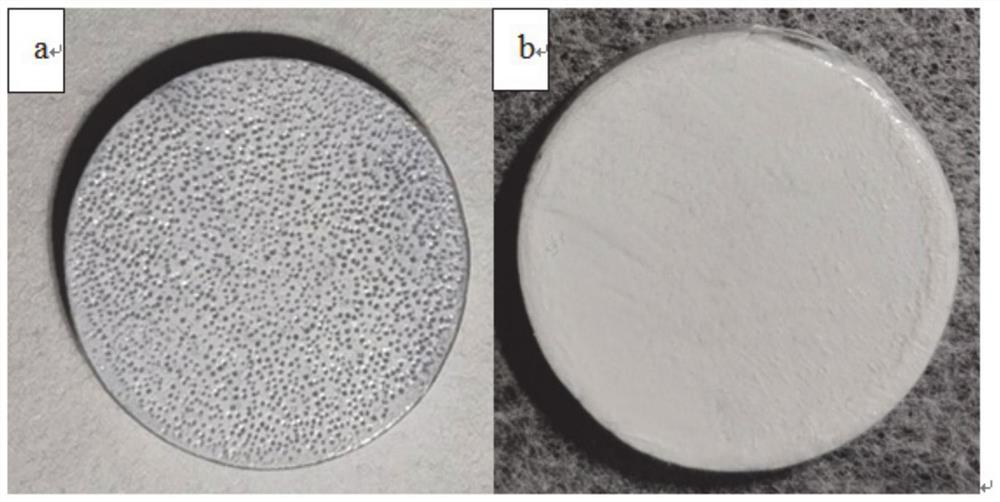

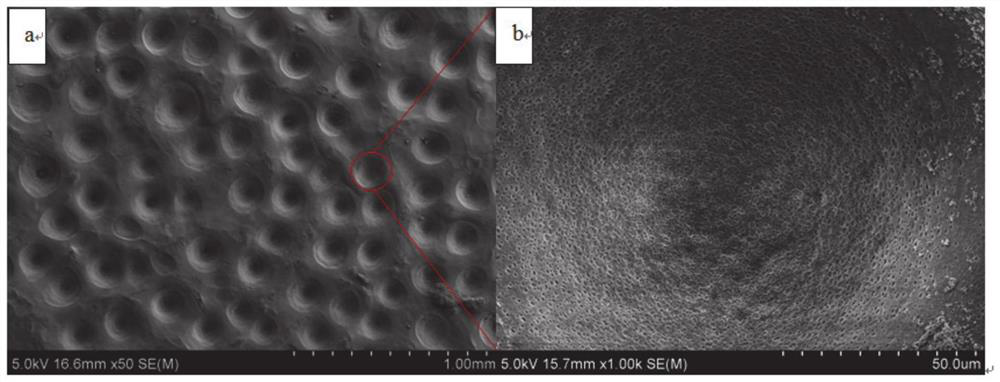

[0039] A method for preparing micro-nano multi-scale pores on the surface of polyether ether ketone, the specific steps are as follows:

[0040] (1) Clean and degrease polyether ether ketone with acetone for 15 minutes at room temperature;

[0041] (2) Soak the sample obtained in step (1) at room temperature in a beaker filled with 98% concentrated sulfuric acid to swell, and place the beaker in an ultrasonic field at the same time. The ultrasonic power is 120W, the ultrasonic frequency is 40kHZ, and the time is 3min. ;

[0042] (3) Wash the sample obtained in step (2) with deionized water for 10 minutes, and place it in a drying oven to dry.

Embodiment 2

[0048] A method for preparing micro-nano multi-scale pores on the surface of polyether ether ketone, the specific steps are as follows:

[0049] (1) Clean and degrease polyether ether ketone with acetone for 15 minutes at room temperature;

[0050] (2) The sample obtained in step (1) is soaked in a beaker filled with 96% concentrated sulfuric acid at room temperature to swell, and the beaker is placed in an ultrasonic cleaner at the same time, the ultrasonic power is 180W, the ultrasonic frequency is 40kHZ, and the time is 5min;

[0051] (3) Wash the sample obtained in step (2) with deionized water for 10 minutes, and place it in a drying oven to dry.

Embodiment 3

[0053] A method for preparing micro-nano multi-scale pores on the surface of polyether ether ketone, the specific steps are as follows:

[0054] (1) Clean and degrease polyether ether ketone with acetone for 15 minutes at room temperature;

[0055] (2) The sample obtained in step (1) is immersed in a beaker filled with 96% concentrated sulfuric acid to swell at room temperature, and the beaker is placed in an ultrasonic cleaner at the same time. The ultrasonic power is 240W, and the ultrasonic frequency is 27.5kHZ. for 10min;

[0056] (3) Wash the sample obtained in step (2) with deionized water for 10 minutes, and place it in a drying oven to dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com