Hydrophobic slurry, liquid diode and preparation method and application of liquid diode

A diode and slurry technology, which can be used in pharmaceutical formulations, textiles and papermaking, etc., can solve problems such as residues and waste, and achieve the effect of reducing loss and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is a preparation method of a liquid diode, comprising the following steps:

[0036] S1. Pretreatment of polyester fabric (polyester woven fabric, warp density is 188 threads / 10cm, weft density is 160 threads / 10cm, fineness is 35tex):

[0037] Wash the polyester fabric, dry it, and iron it for later use.

[0038] S2, preparation of hydrophobic slurry:

[0039] In terms of mass percentage, 80% waterproof agent (Shanghai Saichao Chemical Auxiliary Co., Ltd. MT410), 3% nano silicon dioxide (McLean, particle diameter is 15nm, specific surface area 300 ± 50m 2 / g, CAS No.: 68611-44-9) and 3% thickener (Foshan Chuanhua Fulian Fine Chemical Co., Ltd. ATF) were mixed (the balance was water), and the hydrophobic slurry was obtained under mechanical stirring for 20 minutes.

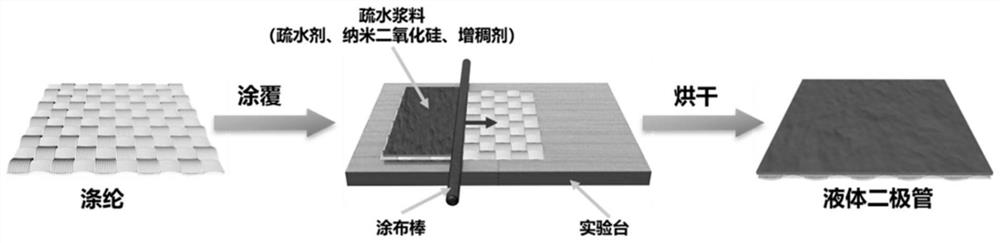

[0040] S3, such as figure 1 As shown, the above-mentioned hydrophobic slurry was coated on one side of the pretreated polyester fabric by the bar coating method, and the coating thickness w...

Embodiment 2

[0042] This embodiment is a preparation method of a liquid diode, comprising the following steps:

[0043] S1. Pretreatment of polyester fabric:

[0044] Wash the polyester fabric (polyester woven fabric, with a warp density of 188 threads / 10cm, a weft density of 160 threads / 10cm, and a fineness of 35tex), dry, and iron for subsequent use.

[0045] S2, preparation of hydrophobic slurry:

[0046] In terms of mass percentage, 80% waterproof agent (Shanghai Saichao Chemical Auxiliary Co., Ltd. MT410), 4% nano silicon dioxide (McLean, particle diameter is 15nm, specific surface area 300 ± 50m 2 / g, CAS No.: 68611-44-9) and 3% thickener (Foshan Chuanhua Fulian Fine Chemical Co., Ltd. ATF) were mixed (the balance was water), and the hydrophobic slurry was obtained under mechanical stirring for 20 minutes.

[0047] S3, such as figure 1 As shown, the above-mentioned hydrophobic slurry was coated on one side of the pretreated polyester fabric by the bar coating method, and the coati...

Embodiment 3

[0049] This embodiment is a preparation method of a liquid diode, comprising the following steps:

[0050] S1. Pretreatment of polyester fabric:

[0051] Wash the polyester fabric (polyester woven fabric, with a warp density of 188 threads / 10cm, a weft density of 160 threads / 10cm, and a fineness of 35tex), dry, and iron for subsequent use.

[0052] S2, preparation of hydrophobic slurry:

[0053] By mass percentage, 80% waterproofing agent (Shanghai Saichao Chemical Auxiliary Co., Ltd. MT410), 5% nano silicon dioxide (McLean, particle diameter is 15nm, specific surface area 300 ± 50m 2 / g, CAS No.: 68611-44-9) and 3% thickener (Foshan Chuanhua Fulian Fine Chemical Co., Ltd. ATF) were mixed (the balance was water), and the hydrophobic slurry was obtained under mechanical stirring for 20 minutes.

[0054] S3, such as figure 1 As shown, the above-mentioned hydrophobic slurry was coated on one side of the pretreated polyester fabric by the bar coating method, and the coating thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com