A kind of carbon-silicon composite adsorbent and its application

A carbon-silicon composite and adsorbent technology, applied in the fields of environmental chemistry and material chemistry, can solve the problem of inability to apply volatile organic waste gas adsorption, and achieve good heat resistance, easy desorption, and high selective adsorption capacity. , the effect of avoiding unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

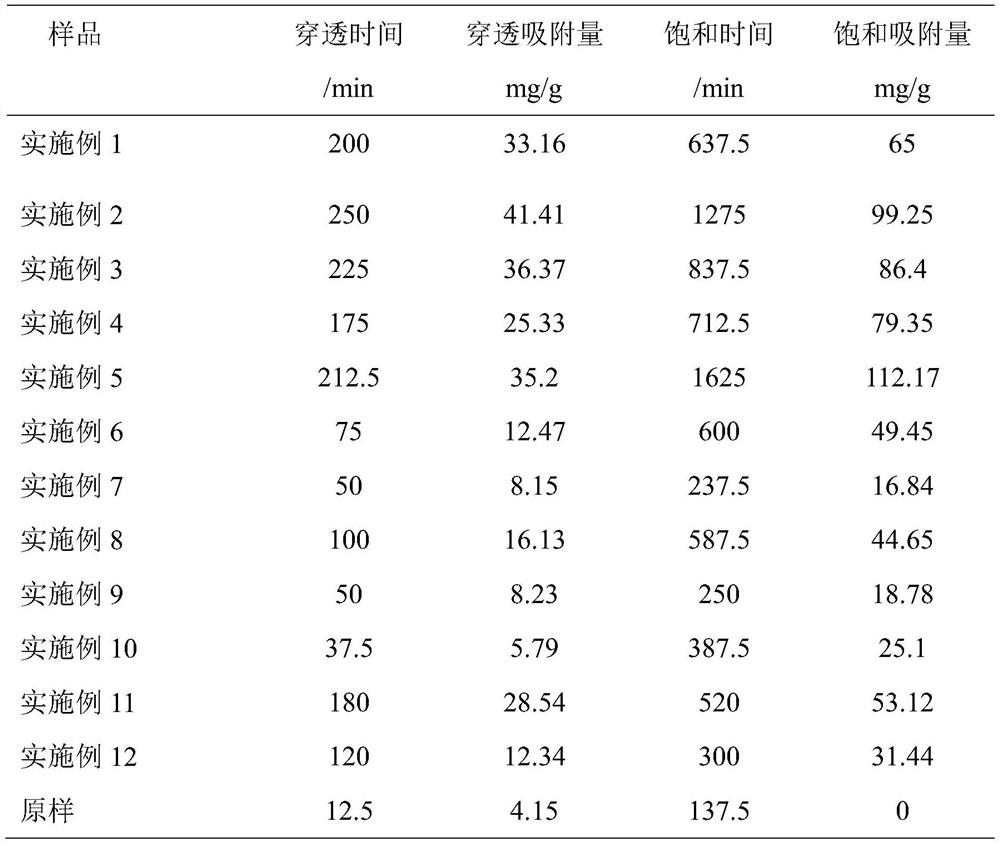

Embodiment 1

[0038] Take 100g of B-type silica gel for pretreatment: wash it with 150ml of ethanol, and dry it in an oven at 110°C for 8h for later use. Soak the pretreated silica gel in 200ml analytical ethanol, add 10% (the ethanol volume is 100%, that is, 20ml) KH-570, condense and reflux at 85°C for 12h, then filter and dry at 110°C to evaporate the ethanol After 24 hours, the silanized silica gel was obtained and stored for future use. Take 3g of sucrose and dissolve it in 12ml of deionized water, stir well to form a 20wt% solution. Put 8g of silanized silica gel into the prepared 20wt% solution, soak it for 8 hours, filter it with a Buchner funnel, put it into a polytetrafluoroethylene liner, put it into a stainless steel reactor, and heat it in water at 180°C for 18 hours. Then cool naturally, wash the hydroheated silica gel several times with deionized water until the charcoal is removed, and dry in an oven at 110°C for 2 hours. Carry out the last step of charcoal burning: placed...

Embodiment 2

[0040] 8 g of sucrose was dissolved in 12 ml of deionized water to form a 40 wt % solution. The rest of the steps are the same as in Example 1 to obtain the sample Sucr-C@Si-0.4. Compared with the original silica gel, the hydrophobicity of this sample has been improved to a certain extent. Compared with the silica gel with a concentration of 20%, the adsorption capacity is significantly increased, indicating that the concentration of the prepared solution has a significant impact on the adsorption capacity.

Embodiment 3

[0042] Get 8g of sucrose and dissolve in 8ml of deionized water to make a 50wt% solution. All other steps are the same as in Example 1 to obtain the product Sucr-C@Si-0.5. Compared with the original silica gel, its p-toluene (5000mg / m 3 ) with a saturated adsorption capacity of 86.4 mg / g and a breakthrough time of 225 min. It shows that there is rich carbon content in the channel, and the effect is remarkable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com