Thick sand layer milling equal-thickness cement soil continuous steel wall forming and slurry parameter control method

A parameter control, cement-soil technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem of unable to reach the effective insertion depth of rigid skeleton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific implementations.

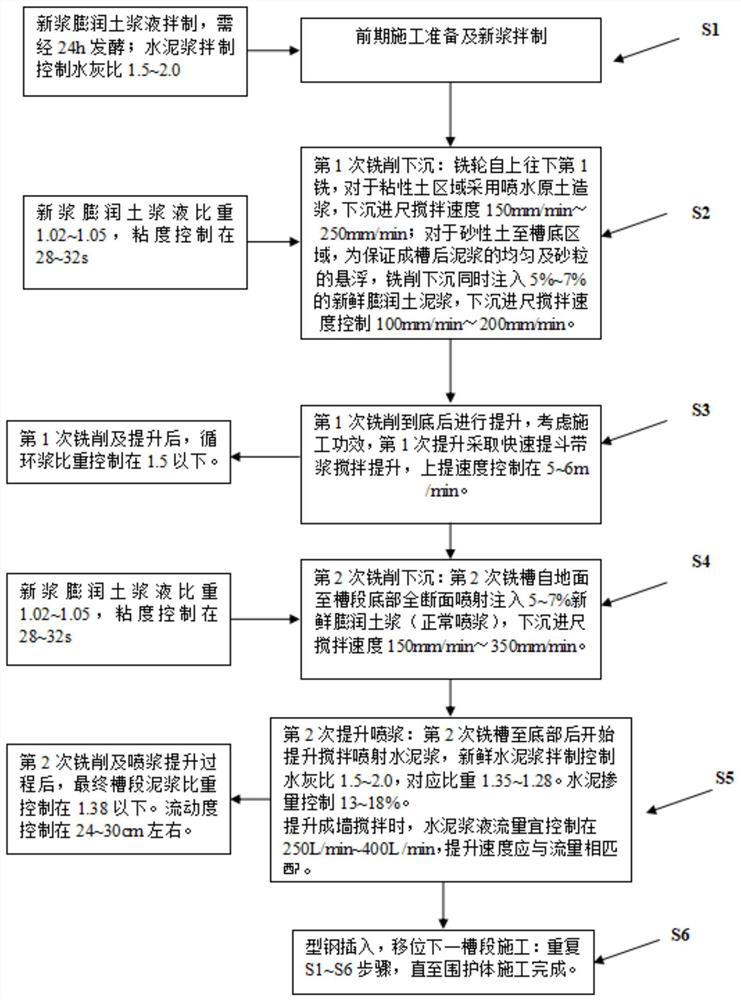

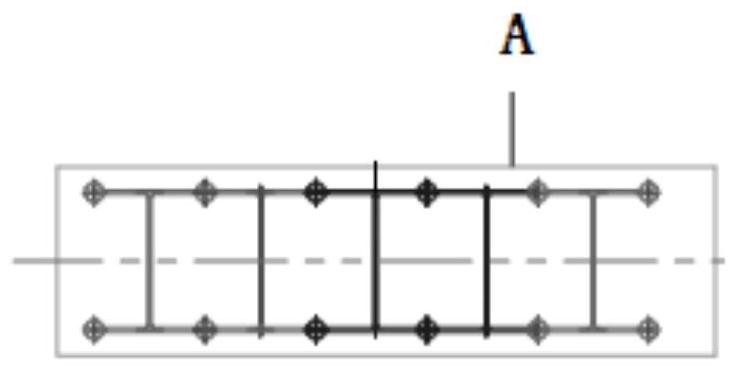

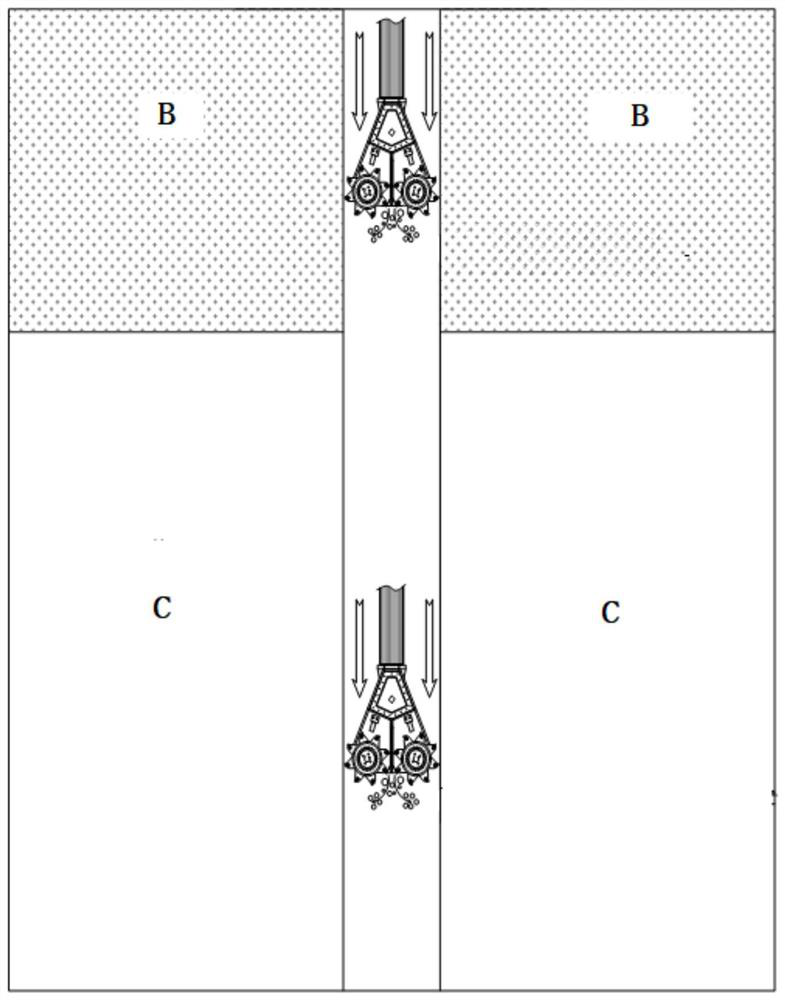

[0032] like Figure 1 to Figure 6 As shown, the construction control method of the present invention is mainly used for thick sand layer milling and other thick cement-soil continuous steel wall A into wall and mud parameter control, and the concrete steps of the method are as follows:

[0033] S1: Pre-construction preparation and new pulp mixing:

[0034] The preliminary preparations mainly include the construction of the guide wall, the debugging and alignment of the milling equipment, and the mixing of fresh mud. Fresh slurries include bentonite slurries and cement slurries. The new bentonite slurry can be put into use only after 24 hours of fermentation. The new pulp is repeatedly stirred during the fermentation process to ensure uniform and full fermentation. After fermentation, the specific gravity of bentonite slurry is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com