Construction method of variable-cross-section edge-grooving round bottom plate assembly type foundation

A construction method and prefabricated technology, which can be applied in basic structure engineering, construction, etc., can solve the problems of large weight of a single basic module, large basic module area, and few longitudinally divided modules, so as to shorten the construction period, simplify the construction, and improve the hoisting and installation. Simple operation and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Best practice:

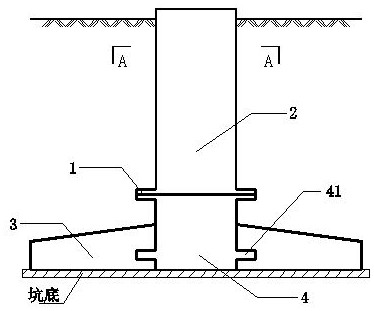

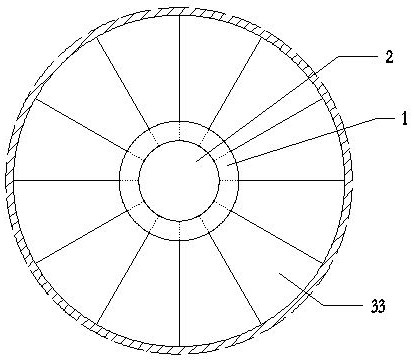

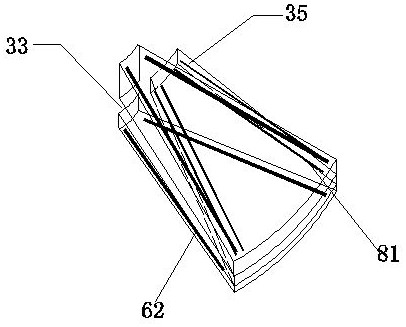

[0043] Refer to attached Figure 1-2, the present invention is firstly based on a variable cross-section "grooving side" circular floor assembled foundation, including a foundation floor and a base column 2, and the foundation floor includes a base 4 installed at the center of the pit bottom and a foundation module body 3, the base 4 has a cylindrical structure, and a plurality of tenon blocks 41 are arranged on the lower circumference of the base 4; Seat 4, the annular cone-column structure includes an upper annular cone-shaped structure 31 and a lower annular cylindrical structure 32, and the upper surface of the annular cone-shaped structure 31 is an inclined surface gradually lowering from the inner ring to the outer ring; The basic module body 3 is divided into 12 identical fan-ring splicing modules 33 corresponding to the tenon blocks on the base; if the base size is small, it can be divided into 8, and if the size is large, it can be divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com