Novel hundred-grade clean room

A clean room, 100-level technology, applied in the clean room field, can solve the problems of costing a lot of manpower and financial resources, not being able to adjust the space, and high construction difficulty, and achieve convenient and simple assembly and disassembly, convenient and simple construction operation, and easy splicing operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

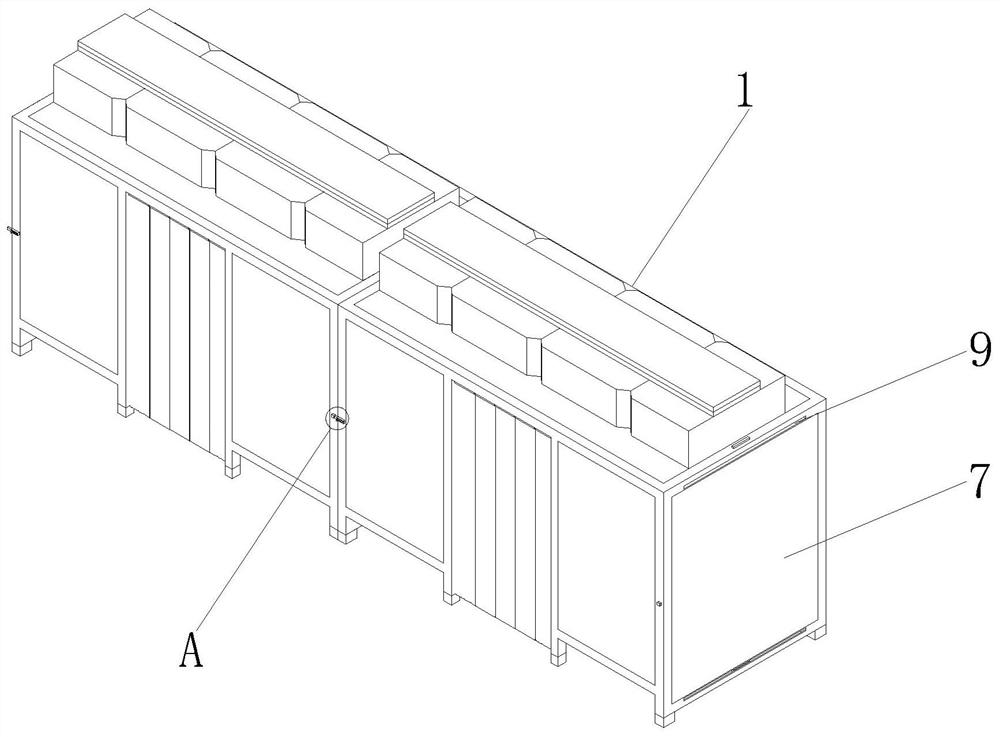

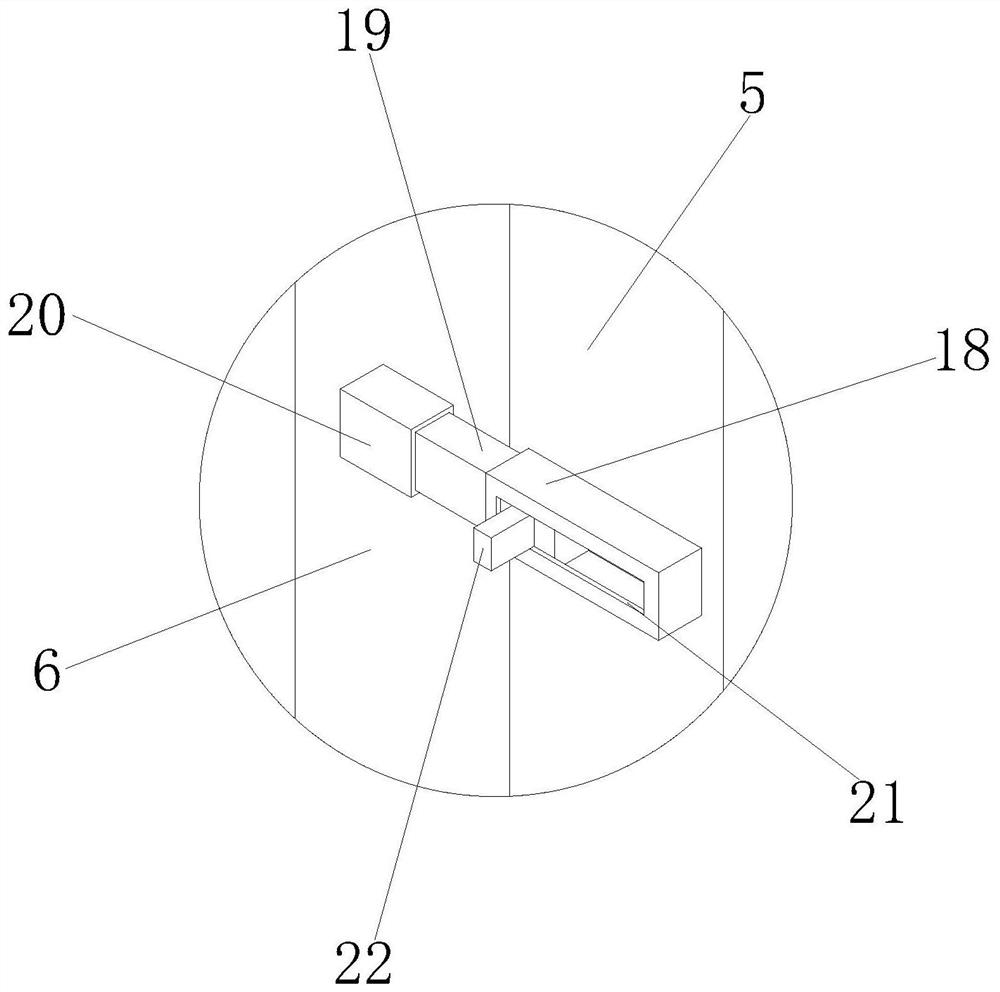

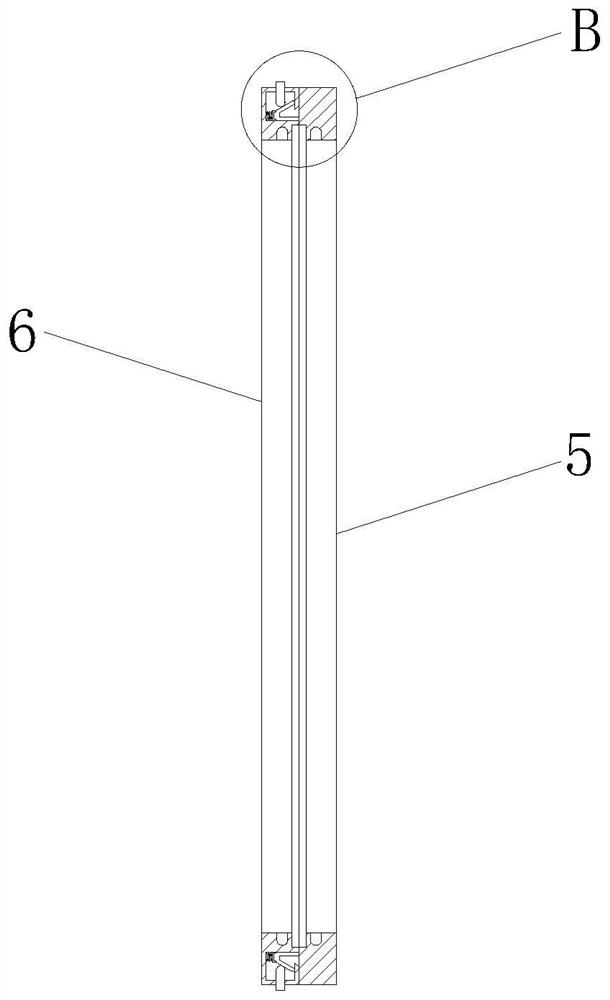

[0037] see figure 1 , image 3 , Figure 4 , Figure 5 As shown, a new class 100 clean room includes several splicing units 1. The splicing unit 1 includes a scaffold 2. Several fan filter units 3 are arranged on the top of the scaffold 2, and a curtain 4 is arranged on the front of the scaffold 2. And the adjacent scaffolds 2 are detachably connected together, the first connecting frame 5 and the second connecting frame 6 are respectively arranged on both ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap