BEST small machine system started in multiple modes and operation method of BEST small machine system

A multi-mode, electric motor technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of affecting the efficiency of small machines, waste of steam waste heat, increasing plant power consumption, etc., to reduce coal consumption, reduce consumption, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with embodiment.

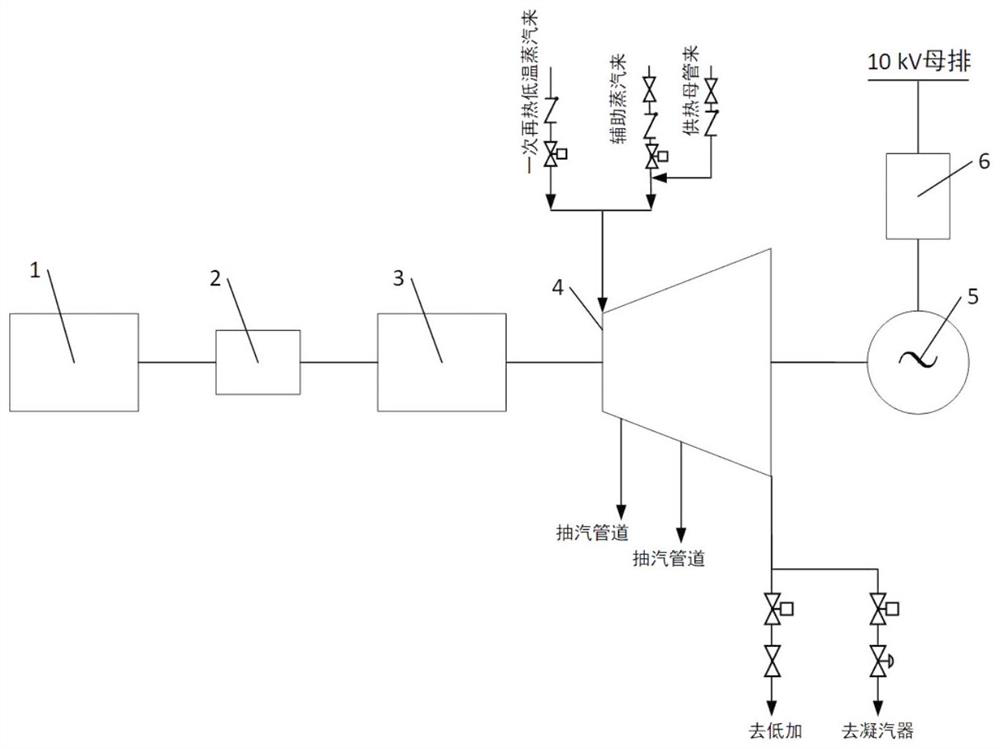

[0025] Such as figure 1 As shown, the main equipment of a multi-mode start-up BEST small machine system includes a front pump 1 , a gear box 2 , a feed water pump 3 , a BEST small machine 4 , a high-speed synchronous motor 5 , and a converter 6 . Also included are some steam pipes.

[0026] In one embodiment, the water feed pump 3, the BEST small machine 4 and the high-speed synchronous motor 5 are connected by the same shaft system. The front pump 1 is connected with the feed water pump 3 through the gear box 2 . The converter 6 is connected to the 10kV busbar of the plant power and the high-speed synchronous motor 5 respectively.

[0027] In one embodiment, the steam pipeline includes a steam incoming pipeline, a steam extraction pipeline and a steam exhaust pipeline.

[0028] In one embodiment, several steam extraction pipes are arranged on the body of the BEST small mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com