A resistance-reducing online cleaning method based on a final cooling tower

A technology of final cooling tower and resistance reduction, applied in the directions of flushing, water shower cooler, cleaning heat transfer device, etc., can solve the problems of deformation and bending, heat rise, etc., and achieve the effect of improving effect, simple operation and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

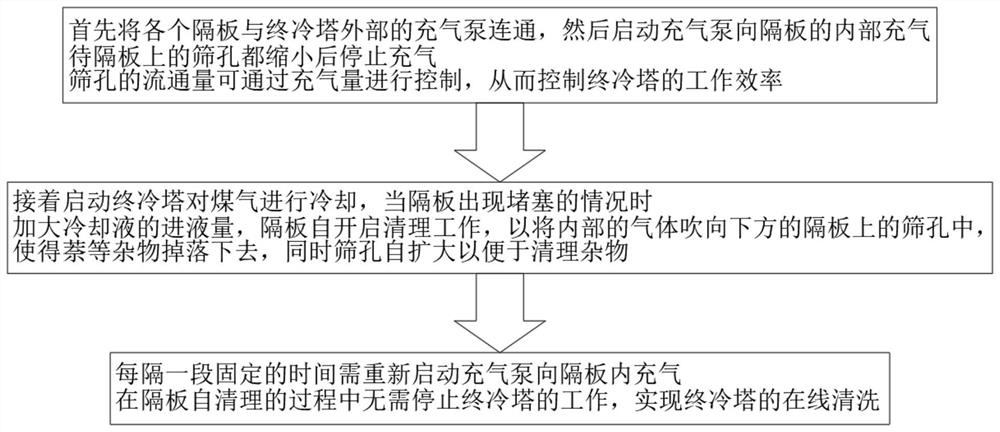

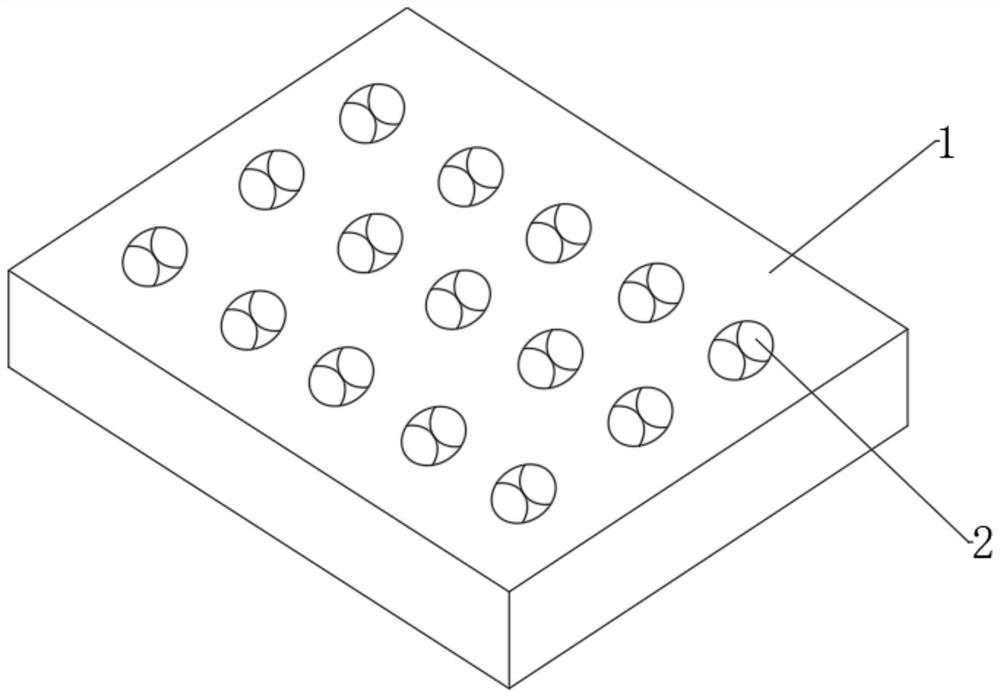

[0050] see Figure 1-11 , a drag-reducing online cleaning method based on a final cooling tower, see figure 1 , including the following cleaning steps:

[0051] S1, first connect each partition 1 with the air pump outside the final cooling tower, then start the air pump to inflate the interior of the partition 1, stop the inflation after the screen holes 101 on the partition 1 are reduced, and the circulation of the screen holes 101 The volume can be controlled by the air filling volume, so as to control the working efficiency of the final cooling tower;

[0052] S2, then start the final cooling tower to cool the gas. When the partition 1 is blocked, increase the liquid intake of the cooling liquid, and the partition 1 will automatically open and clean to blow the internal gas to the lower partition 1, so that sundries such as naphthalene fall down, and at the same time, the screen hole 101 expands to facilitate cleaning of sundries;

[0053] S3, the air pump needs to be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com