Computer vision measurement device

A technology of computer vision and measuring devices, which is applied in the directions of measuring devices, testing plant materials, and material analysis through optical means. It can solve problems such as deviation of measurement results, influence of research, troubles, etc., and achieve the effect of increasing contrast and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is:

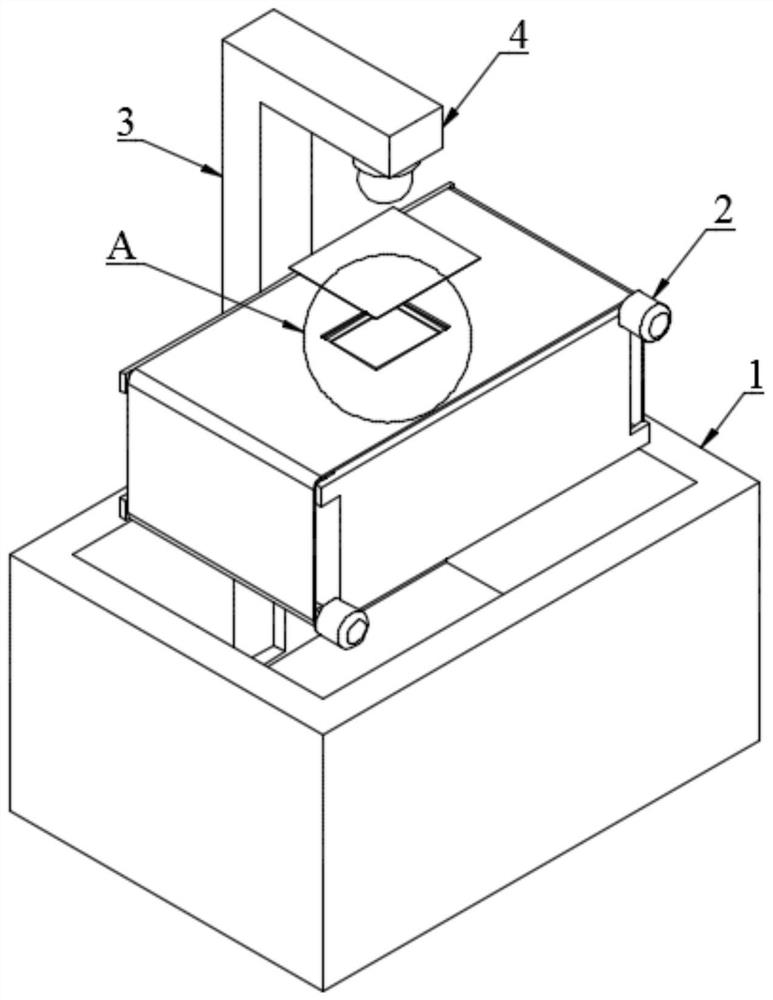

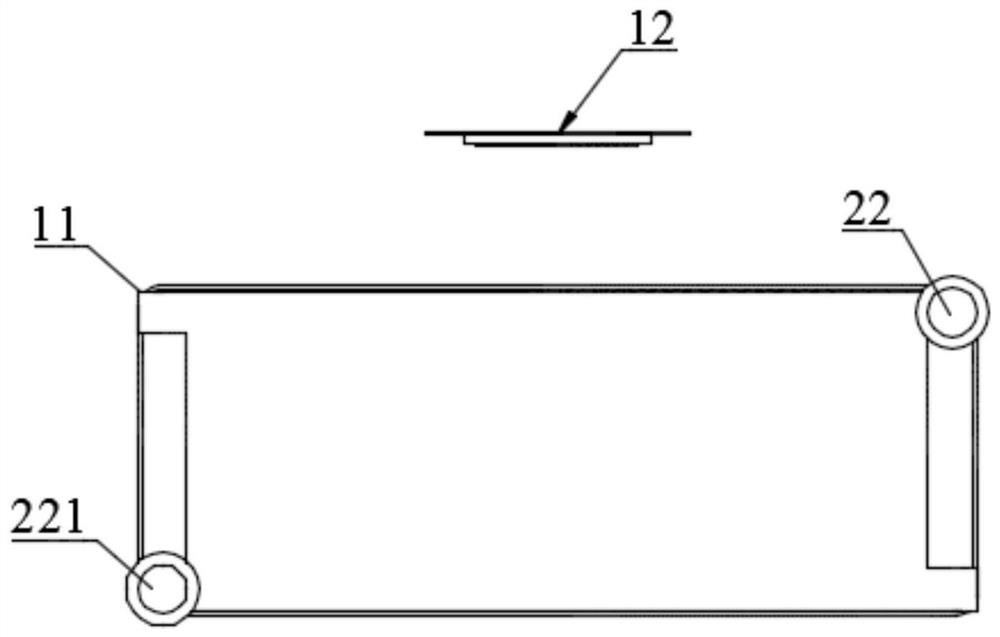

[0061] A computer vision measurement device includes a placement table 1, a background moving component 2, a support frame 3, an image acquisition component and an image processing component.

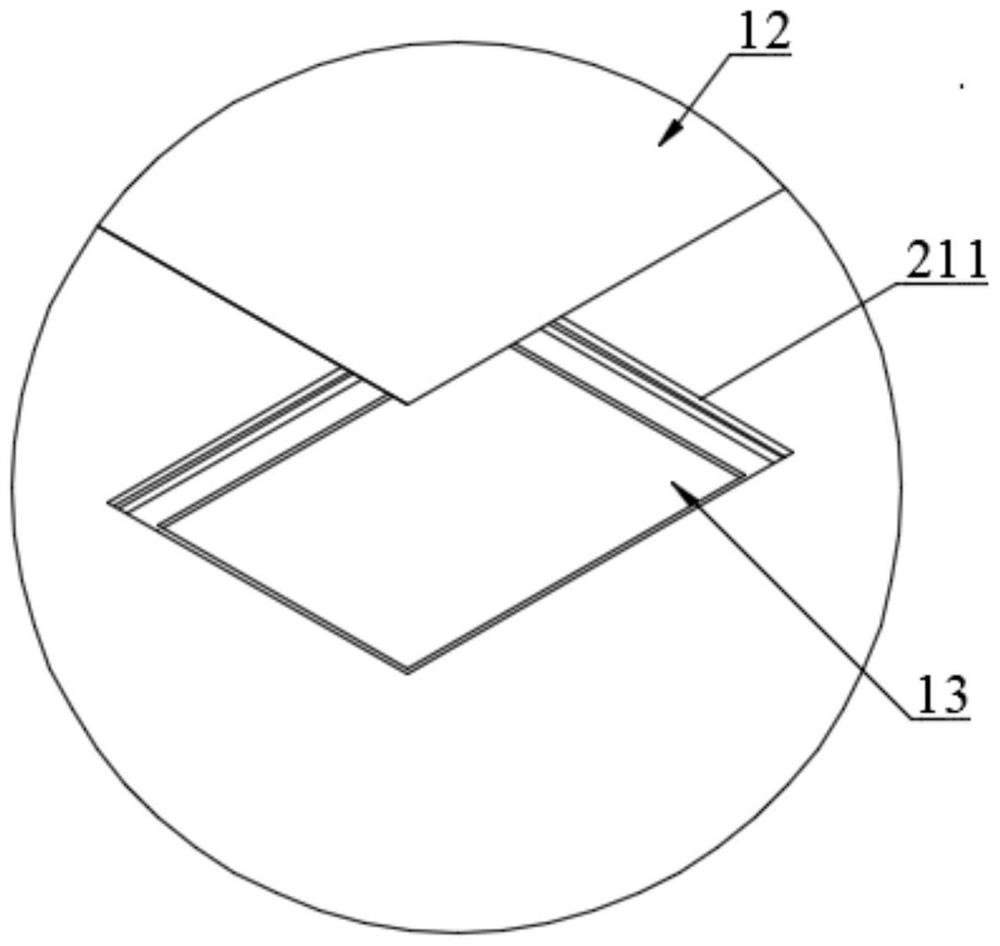

[0062] Such as figure 1 , figure 2 and Figure 5 It can be seen that the placement table 1 includes a placement surface 11 , a carrier 12 located on the placement surface 11 and a groove 13 corresponding to the carrier 12 , the bottom of the groove 13 is provided with a magnetic change component 14 that can exhibit different polarities.

[0063] Such as Figure 5 As shown, the stage 12 includes a flat magnet 121 arranged in the middle of the bottom near the groove 13, a flat plate-shaped pressing plate 122 extending outward on four sides of the top, and a first stepped surface facing inward on the four sides of the bottom. 123 . On the side of the flat magnet 121 away from the magnetic chang...

Embodiment 2

[0076] Please refer to Figure 1 to Figure 6 , the second embodiment of the present invention is:

[0077] A computer vision measurement device, on the basis of the first embodiment above, the placing table 1 is further provided with at least one second rotating shaft 223 between the two sides of one of the two sides of the rotating path of the flexible member, And a third rotating shaft 224 corresponding to the number position of the second rotating shaft 223 is provided at a position close to the other side, and the flexible member sequentially passes through the first rotating shaft 222 on the upper side on the side where the second rotating shaft 223 is provided, The second rotating shaft 223 located in between, the third rotating shaft 224 located near the other side, and the first rotating shaft 222 located below form a zigzag structure.

[0078] Therefore, in this embodiment, four placement backgrounds 21 can be placed, and more placement backgrounds 21 can be placed b...

Embodiment 3

[0079] Please refer to Figure 1 to Figure 5 as well as Figure 7 to Figure 9 , Embodiment three of the present invention is:

[0080] A computer vision measuring device, on the basis of the first embodiment above, the annular electromagnet 141 is a strong magnet, at this time, a magnetic isolation material can be arranged around and at the bottom of the strong magnet, so that it only generates magnetic force upward.

[0081] In this embodiment, a turntable 5 , a turn bar 6 , a splicing plate 7 and a second motor 8 are also included. Wherein the output shaft of the second motor 8 is connected to the bottom of the turntable 5, the turntable 5 is provided with a guide groove 51 from the inside to the outside, and the four splicing plates 7 are diagonally spliced into a rectangle matching the bottom of the groove 13, each The bottom of each splicing plate 7 is connected with one end of a rotating rod 6 , and the other end of the rotating rod 6 is located in the guide groove 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com