Noise reduction method for ultrasonic detection signal of metal internal defect

A technology for metal internal defects and ultrasonic detection, which is applied in the identification of patterns in signals, processing of detected response signals, and material analysis using sonic/ultrasonic/infrasonic waves. It can solve the problem of low signal-to-noise ratio and inability to obtain noise reduction effects , it is difficult to obtain sparse decomposition results, etc., to achieve the effect of suppressing noise components, high reference and reference significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present disclosure will be described in detail below in conjunction with the accompanying drawings.

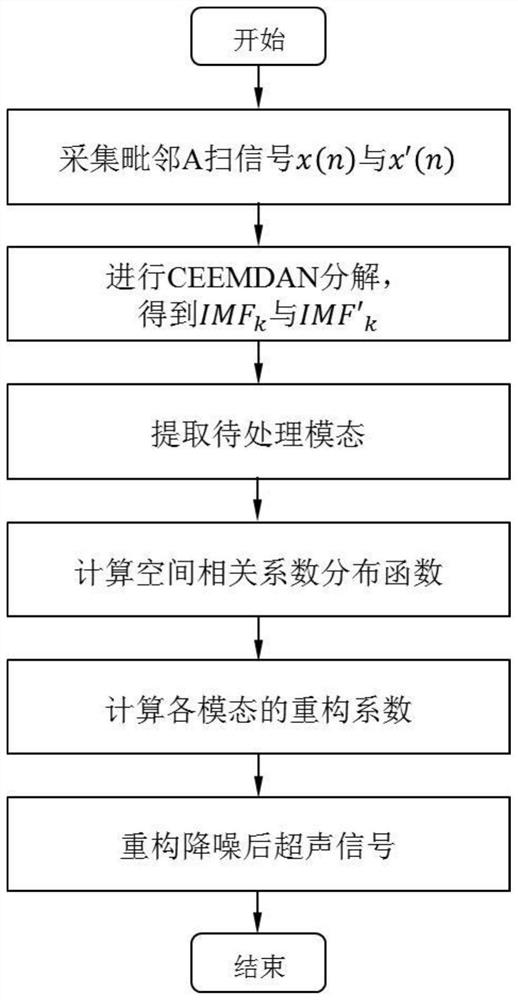

[0029] figure 1 It is a flowchart of the method described in this application, such as figure 1 As shown, the method specifically includes:

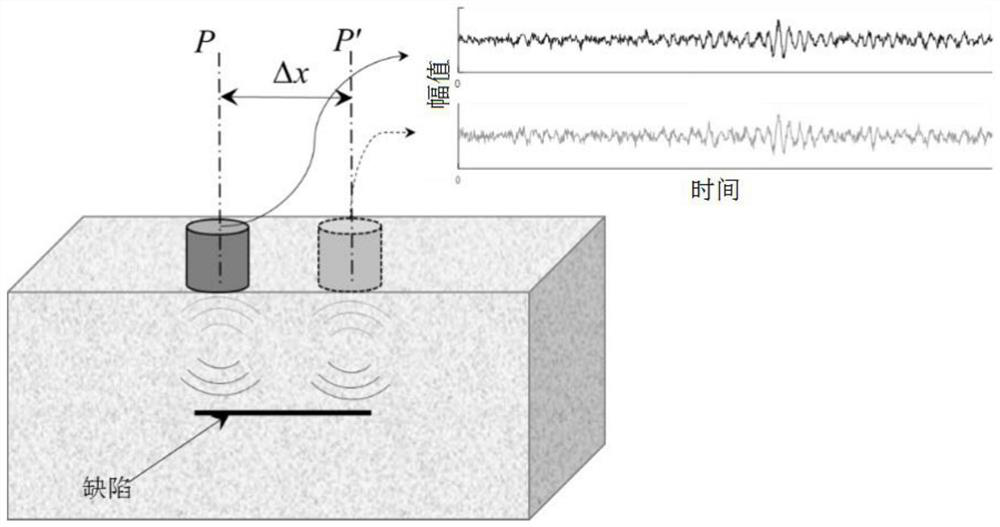

[0030] Step S1: collect ultrasonic A-scan signals at two adjacent detection positions P and P′ respectively, cut off the initial wave and bottom wave part of the ultrasonic A-scan signal, and obtain the ultrasonic detection signal x( n) is spatially correlated with the reference signal x'(n) at the detection position P'.

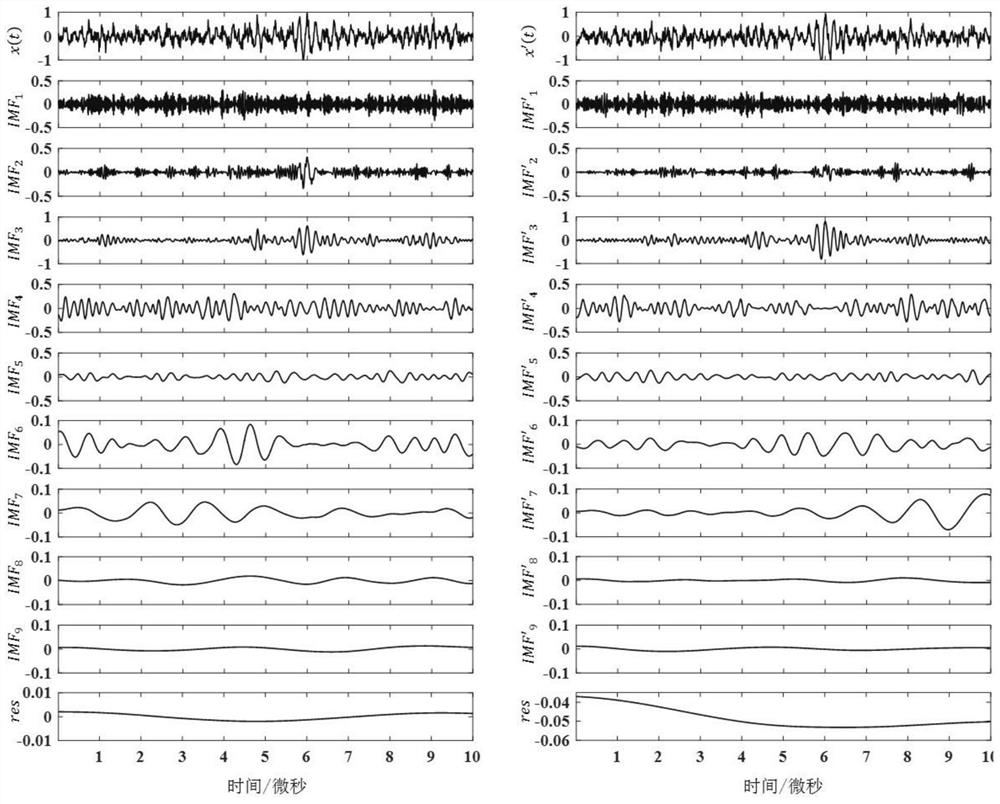

[0031] Step S2: Decompose the x(n) and x'(n) respectively using the CEEMDAN algorithm to obtain the modal IMF respectively k (n) with modal IMF' k' (n); among them, k=1,2,3,...,K; k'=1,2,3,...,K'; when k=k', the modal IMF k (n) with modal IMF' k' (n) is called a pair of parallel modes.

[0032] Specifically, step S2 includes:

[0033] Step S21: through the EMD algorithm to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com