Detection data analysis and repair method of train wheel rim tread

A technology for detecting data and repairing methods, applied in program control, instrumentation, computer control, etc., can solve problems such as difficulty in ensuring the pertinence of correction processing and consistency of batch correction, affecting wheel life, gross errors, etc., and achieving good generalization Features, Improved Accuracy, Strong Robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

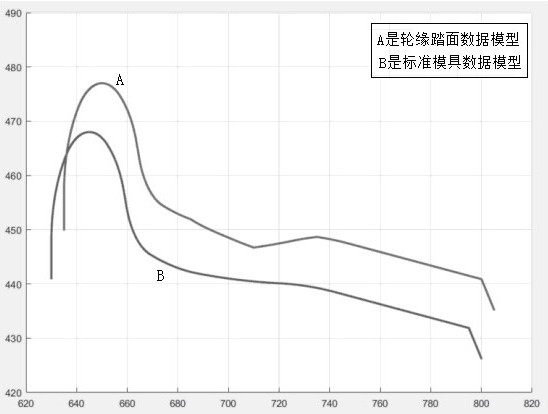

[0040] A detection data analysis and repair method of a train wheel rim tread of the present invention mainly includes several links of data collection, model building, model comparison, and result output, specifically including the following steps:

[0041] Step 1: Select a standard mold from the candidate mold library, and draw a standard mold data model according to multiple contour two-dimensional coordinate data of the standard mold.

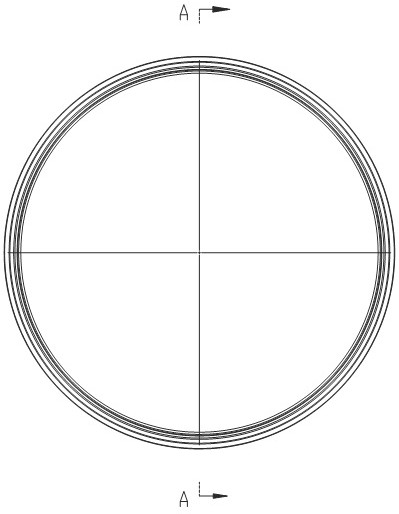

[0042] Step 2: collecting a plurality of two-dimensional coordinate data of the contour line of the worn rim tread through the machine tool detection system, and drawing a data model of the wheel rim tread according to the plurality of two-dimensional coordinate data of the contour line. The step 2 includes:

[0043] Step 2.1: Collect multiple two-dimensional coordinate data of the contour line of the worn rim tread, and ensure that the ordinate of the starting position is greater than the ordinate of the starting position of the standard mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com