Wavelength conversion device, manufacturing method thereof and backlight source

A technology of wavelength conversion and manufacturing method, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of short life of wavelength conversion devices and low effective utilization of LED light emission, and achieve good energy saving and reliability, and improve Effective utilization and the effect of eliminating optical crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with examples, but the present invention is not limited to these examples.

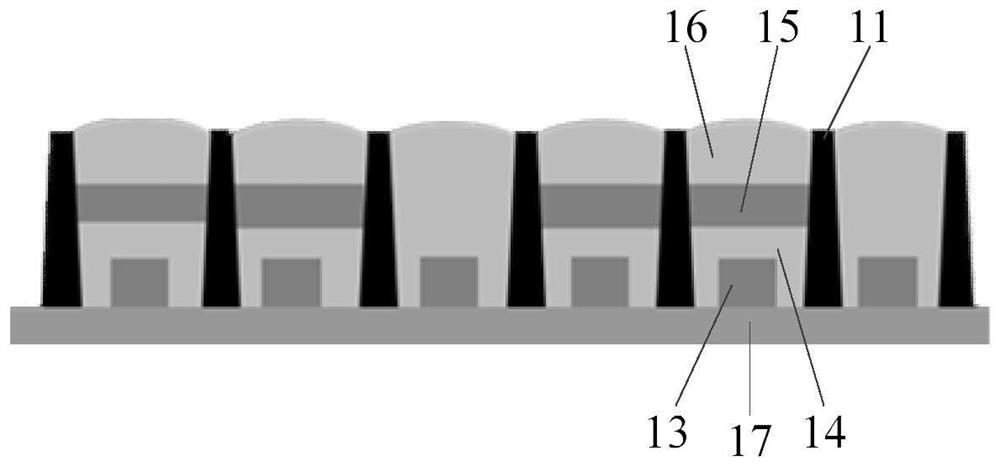

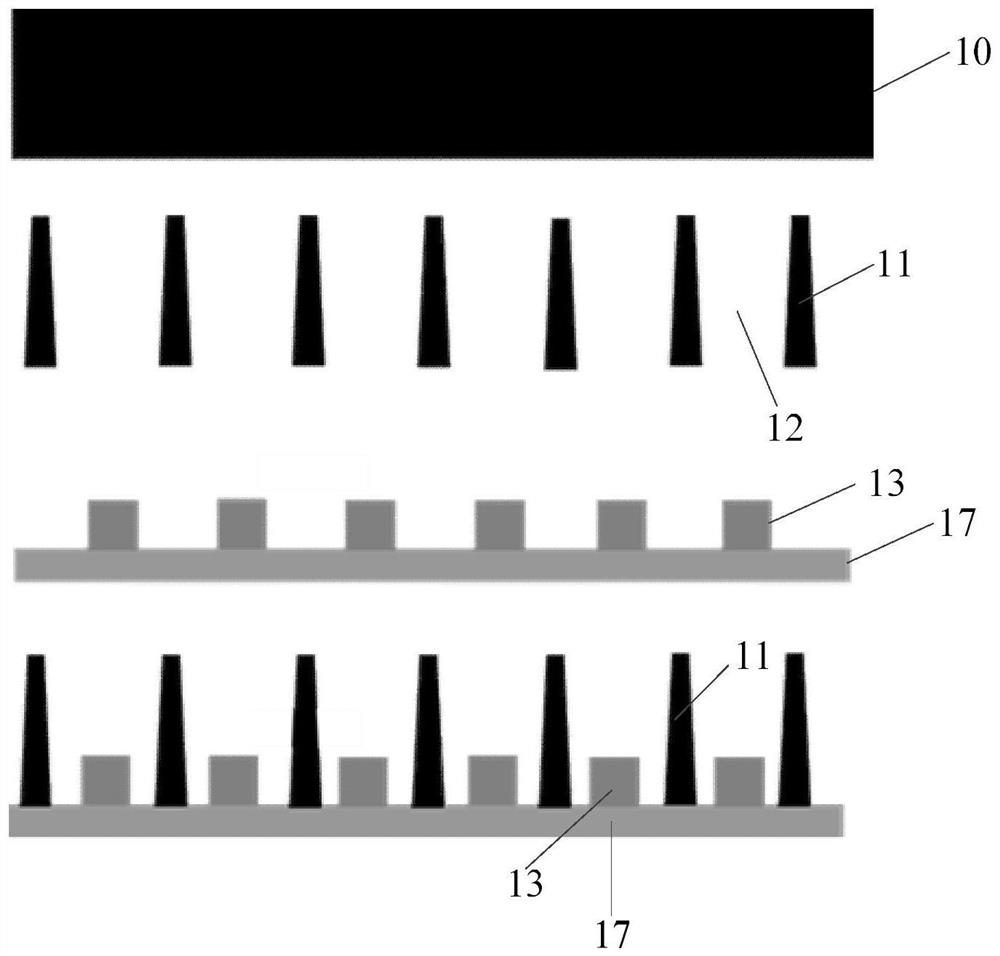

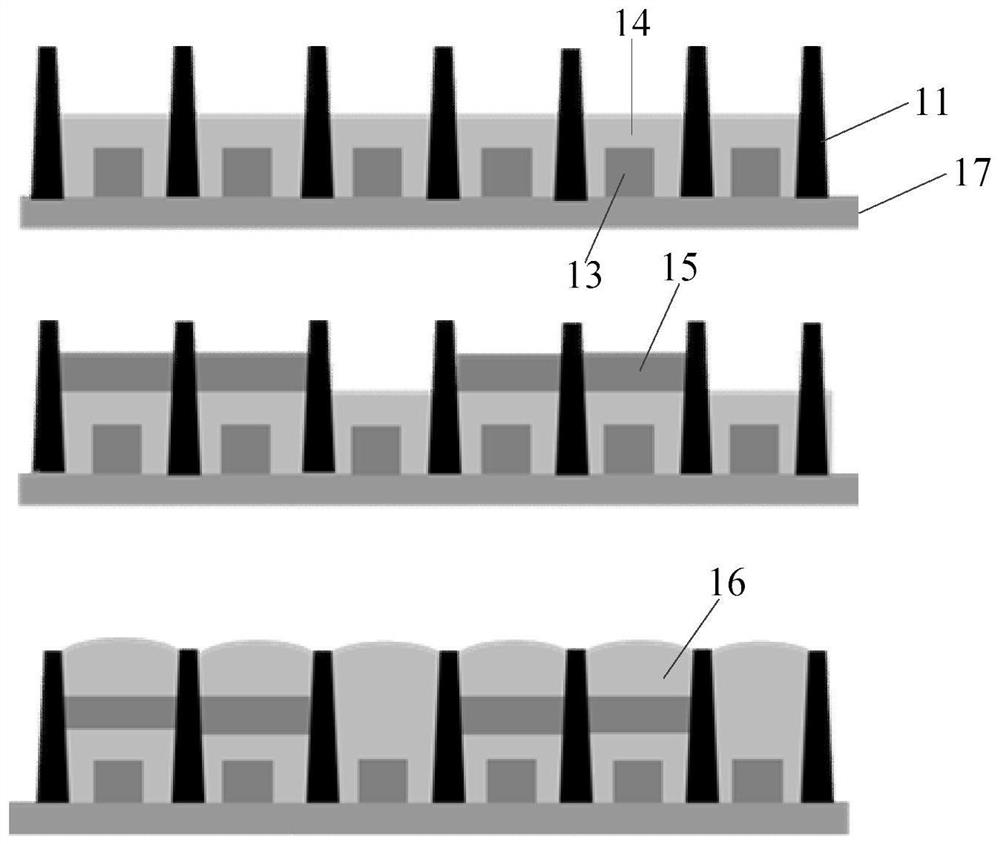

[0033] An embodiment of the present invention provides a wavelength conversion device, referring to Figure 1 to Figure 5 As shown, it includes a metal mesh plate 11; a plurality of through holes 12 are arranged in an array on the metal mesh plate 11, and the through holes 12 are used to place the light source 13; An encapsulation adhesive layer 14, a wavelength conversion layer 15 and a second encapsulation adhesive layer 16; the light source 13 is used to emit the light of the first waveband, and the light of the first waveband is generally blue light; the wavelength conversion layer 15 is used for converting the first waveband The light in the second waveband is converted into light in the second waveband, and the light in the second waveband is generally red light and / or green light.

[0034] Wherein, the metal mesh plate 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com