Panel furniture and assembling method

A panel-type furniture and assembly method technology, which is applied to home appliances, furniture parts, furniture connectors, etc., can solve the problems of time-consuming and labor-consuming hardware, poor customer experience, and complicated production processes, etc., so as to improve the utilization rate of equipment , strong connection and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

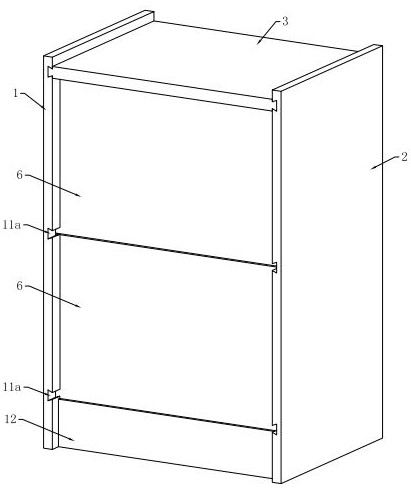

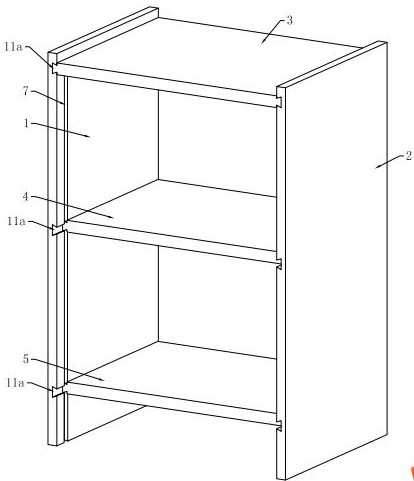

[0045] Such as Figure 1 to Figure 8 Commonly shown, a panel furniture includes a right side panel 1 and a left side panel 2, and also includes a back panel 6, a skirting board 12, and a top panel 3 sequentially arranged between the right side panel 1 and the left side panel 2 from top to bottom , Partition 4 and bottom plate 5. During actual production, the number of partitions 4 can be set according to the size of the panel furniture and actual needs, which can be one partition 4 or two or more partitions 4 . In this embodiment, a partition 4 is taken as an example to illustrate the structure of panel furniture.

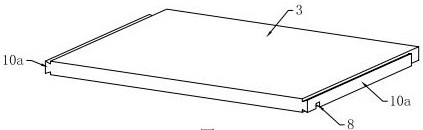

[0046] Both the right side panel 1 and the left side panel 2 are spliced with the top panel 3 , the partition panel 4 and the bottom panel 5 through the dovetail tenon and tenon structure. The left and right ends of the top plate 3, the left and right ends of the partition plate 4, and the left and right ends of the bottom plate 5 are all provided with dovetail...

Embodiment 2

[0057] The difference between this embodiment and the first embodiment is that the dovetails on the top plate 3 , partition plate 4 and bottom plate 5 are segmented dovetails. Such as Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 Commonly shown, the two ends of the top plate 3, the two ends of the partition plate 4 and the two ends of the bottom plate 5 are all provided with two or more sections of dovetails 10b arranged at intervals, and the right side plate 1 and the left side plate 2 are provided with dovetail joints. The tenon 10b matches the dovetail tenon 11b. And the side of the dovetail 11b is provided with a pre-installation notch 13, and the pre-installation notch 13 communicates with the dovetail 11b. Preferably in this embodiment, two spaced dovetails 10 b are provided on the left and right ends of the top plate 3 , the partition plate 4 and the bottom plate 5 . During installation, the dovetail tenon 10b is installed in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com