Long rod type automatic fastening device

The technology of a fastening device and a long rod is applied in the field of long rod type automatic fastening tools, which can solve the problems of inflexible use and difficult operation, and achieve the effects of easy and convenient operation, flexible operation and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

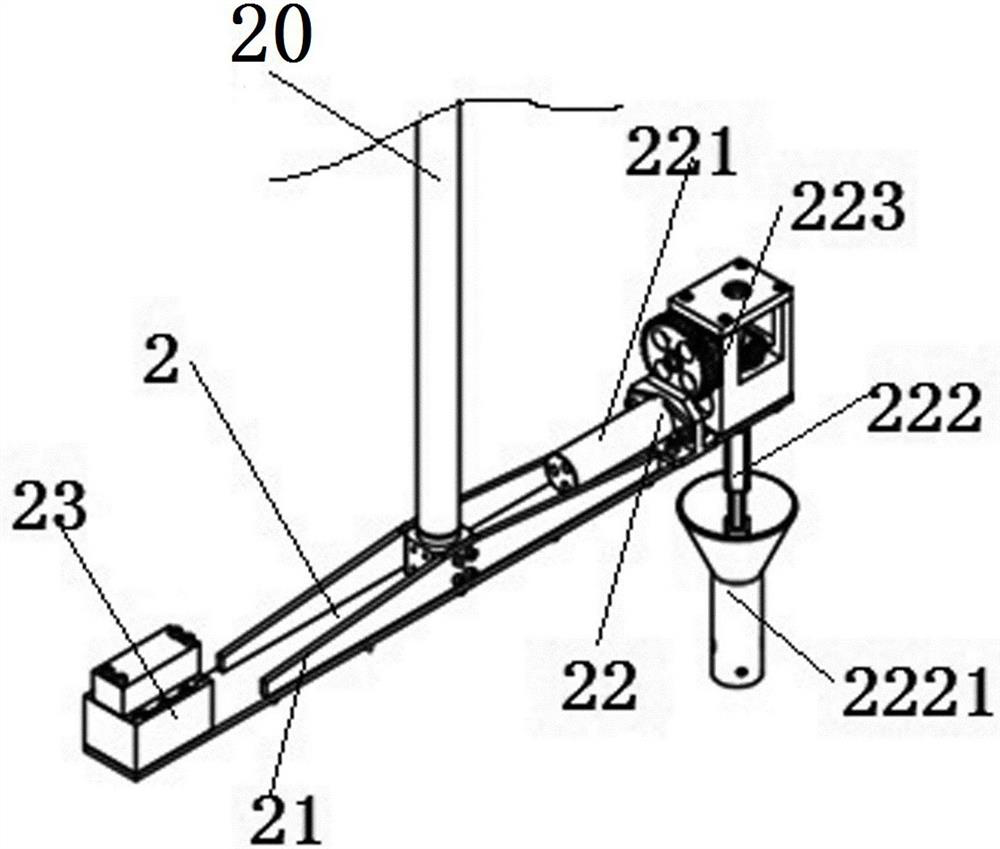

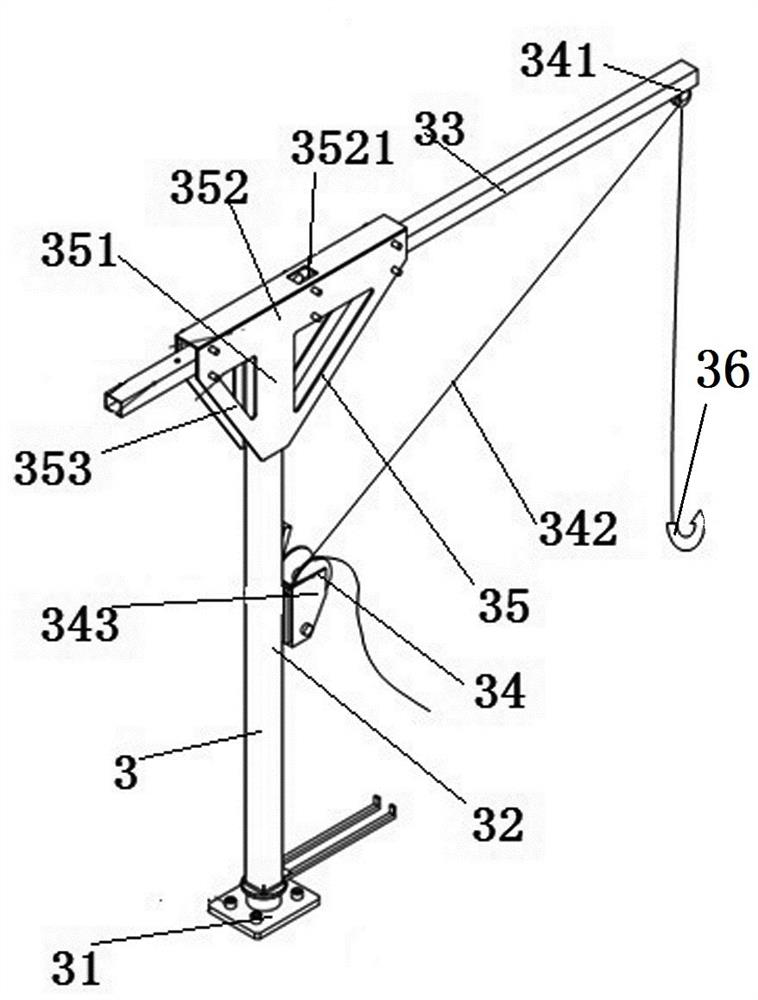

[0034] A long rod type automatic fastening device, comprising a tightening assembly 2 and a hanging assembly 3; the hanging assembly 3 has a liftable hanging head 36; the tightening assembly 2 includes a first cross bar 21, one end and The hanging head 36 is connected to the long bar 20 whose other end is fixed to the first cross bar 21 and the driving unit 22 and the counterweight unit 23 respectively arranged at both ends of the first cross bar 21. The driving unit 22 It includes an operating head 222 and a driving motor 221 that drives the operating head 222 .

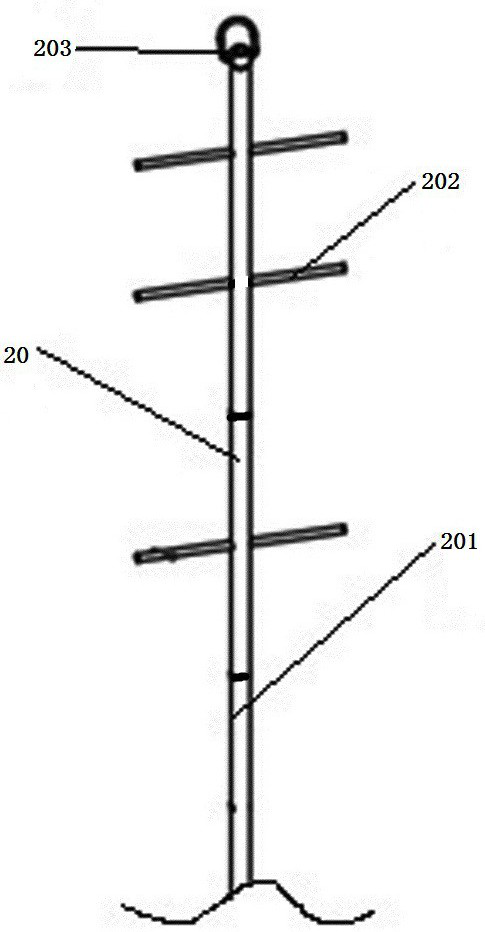

[0035] The long pole 20 is composed of a plurality of connecting units 201, and the length of each connecting unit 201 is 3-4m.

[0036] The long pole 20 is provided with at least one second crossbar 202 which is convenient for rotation operation.

[0037] A reduction gear set 223 is disposed between the driving motor 221 and the operating head 222 .

[0038] The operation head 222 is sheathed with a guide sleeve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com