Bottle opener for glass bottle beer

A bottle lifter and beer technology, which is applied in the direction of flange-type cap disassembly, etc., can solve the problems of unable to collect bottle caps, unable to clamp bottle caps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

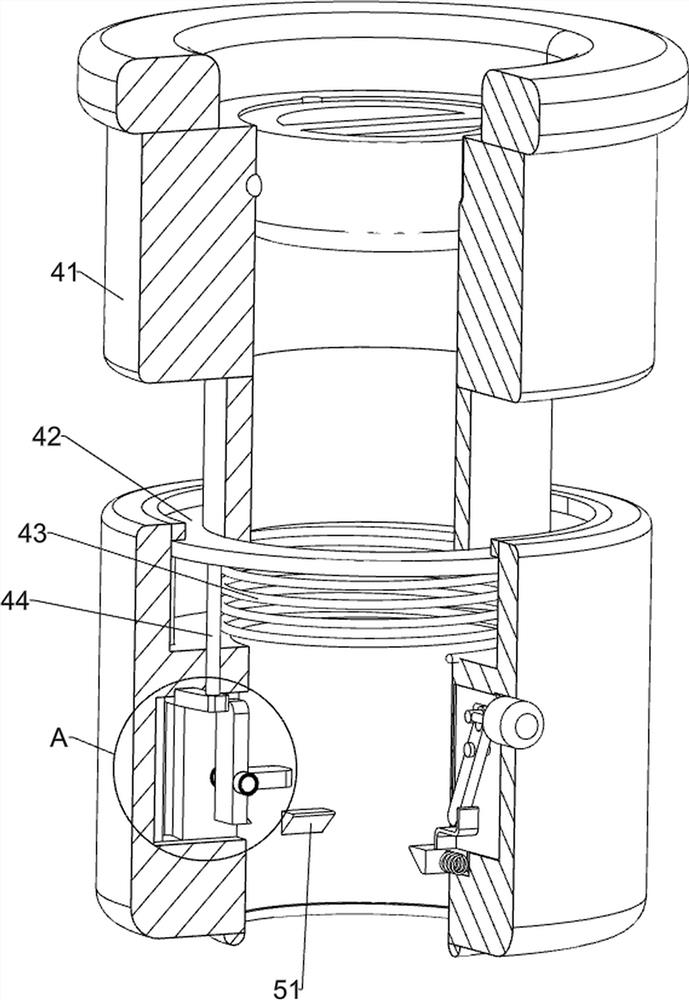

[0028] A bottle opener for glass bottles of beer such as figure 1 , figure 2 , image 3 and Figure 5 As shown, it includes a casing 1 , a protection ring 2 , a hook assembly 3 and a trigger assembly 4 , the bottom of the casing 1 is connected with the protection ring 2 , and the casing 1 is provided with a hook assembly 3 and a trigger assembly 4 respectively.

[0029] The hook assembly 3 includes a scroll spring 32, a connecting shaft 33, a trigger plate 34, a seesaw 35 and a locking tooth 36. The inner walls of the left and right sides of the casing 1 are provided with placement grooves 31, and the casing 1 in the placement groove 31 rotates A connecting shaft 33 is connected in the same way, two scroll springs 32 are connected between the connecting shaft 33 and the inner wall of the housing 1, a seesaw 35 is connected on the connecting shaft 33, a trigger plate 34 is connected to the inner side of the seesaw 35, and a seesaw 35 A locking tooth 36 is connected to the l...

Embodiment 2

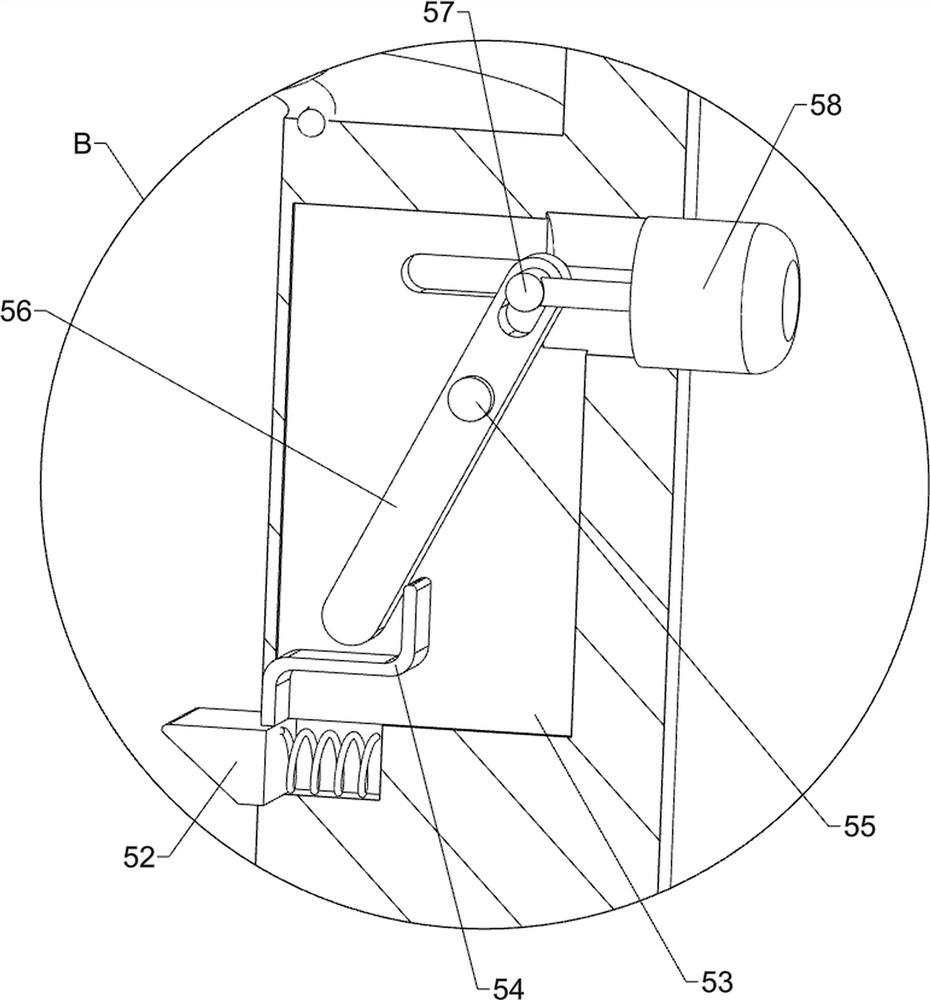

[0033] On the basis of Example 1, such as figure 2 , image 3 and Figure 6 As shown, a clip cover assembly 5 is also included, and the clip cover assembly 5 includes a first elastic block 51, a second elastic block 52, a pull plate frame 54, a fixed shaft 55, a slotted connecting rod 56, a push frame 57 and The button 58 is slidably connected with a first elastic block 51 on the rear side of the shell 1, and is slidably connected with a second elastic block 52 on the front side of the shell 1, and the top of the second elastic block 52 is connected with a pull plate frame 54, The front side in the housing 1 has a mounting groove 53, the housing 1 in the mounting groove 53 is connected with a fixed shaft 55, and the fixed shaft 55 is rotatably connected with a slotted connecting rod 56. 54 contact fits, slotted connecting rod 56 tops are slidably connected with a push frame 57, and the push frame 57 is slidably connected with the shell 1, and the push frame 57 is connected ...

Embodiment 3

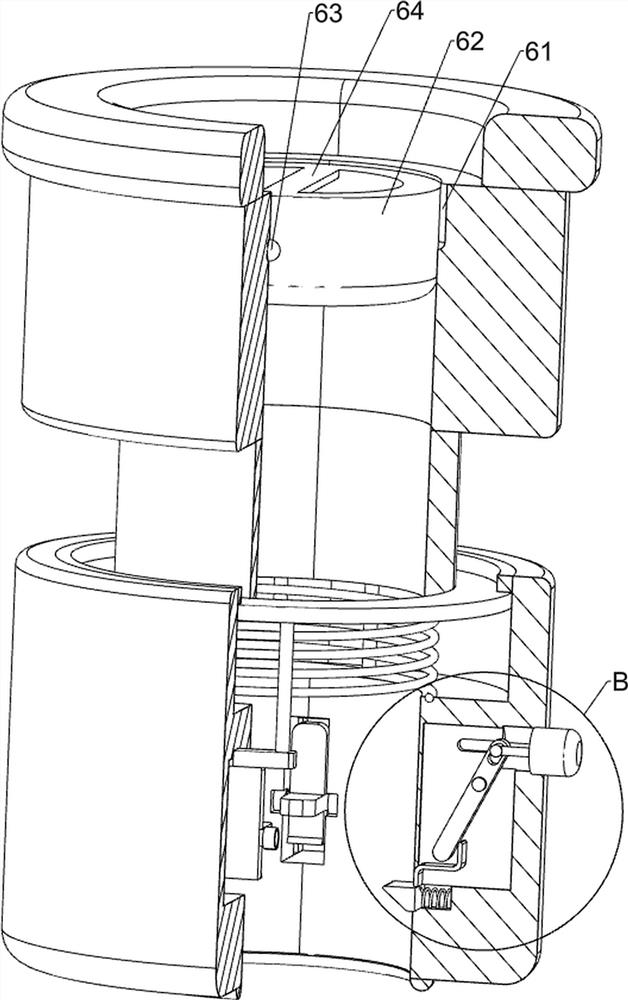

[0036] On the basis of Example 2, such as figure 2 and Figure 4 As shown, a movable cover assembly 6 is also included. The movable cover assembly 6 includes a plug cover 62, a fixed block 63 and a hand-twist block 64. Two locking grooves 61 are symmetrically opened on the inner wall of the extrusion barrel 41, and the extrusion barrel A plug 62 is placed on the top of the inner wall of 41, and the outer wall of the plug 62 is connected with two fixed blocks 63, the fixed blocks 63 cooperate with the locking groove 61, and the top of the plug 62 is connected with a hand-twist block 64.

[0037]The squeeze barrel 41 can be plugged by the plug cover 62, thereby preventing impurities such as dust from entering the shell 1 and the squeeze barrel 41. Twist the block 64 by hand so that the plug cover 62 rotates, and the plug cover 62 rotates to drive the fixed block 63 to rotate. The deformed bottle cap of prying is taken out through extrusion barrel 41, and after bottle cap is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com